Environment-friendly water-oil automatic segregation water tank

An automatic separation and water-oil separation technology, applied in the direction of filtration separation, liquid separation, separation methods, etc., can solve the problems of poor effect, inconvenient operation of water-oil separation, etc., and achieve reasonable structural design, simple operation, and good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with accompanying drawing, the present invention will be further described.

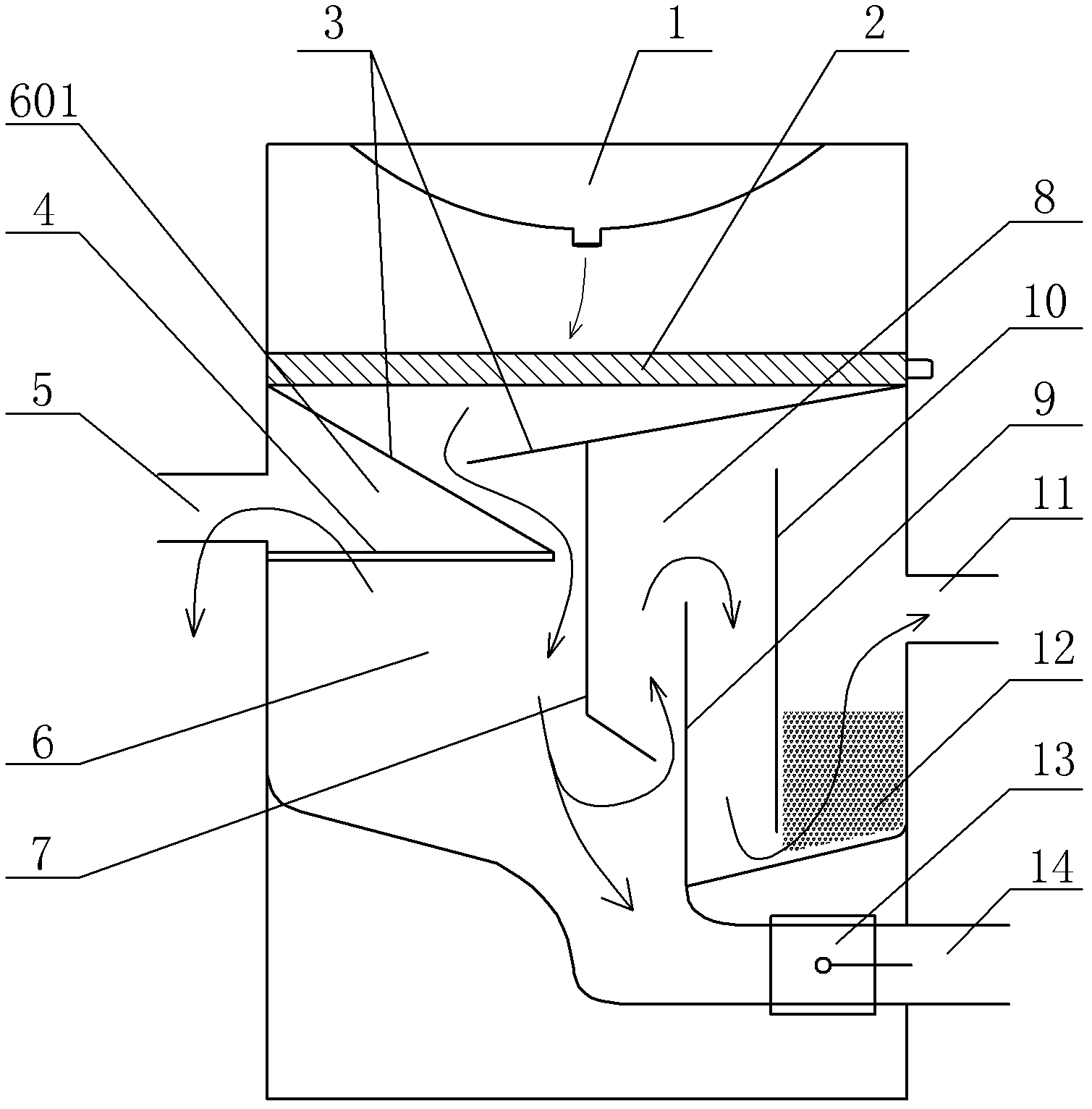

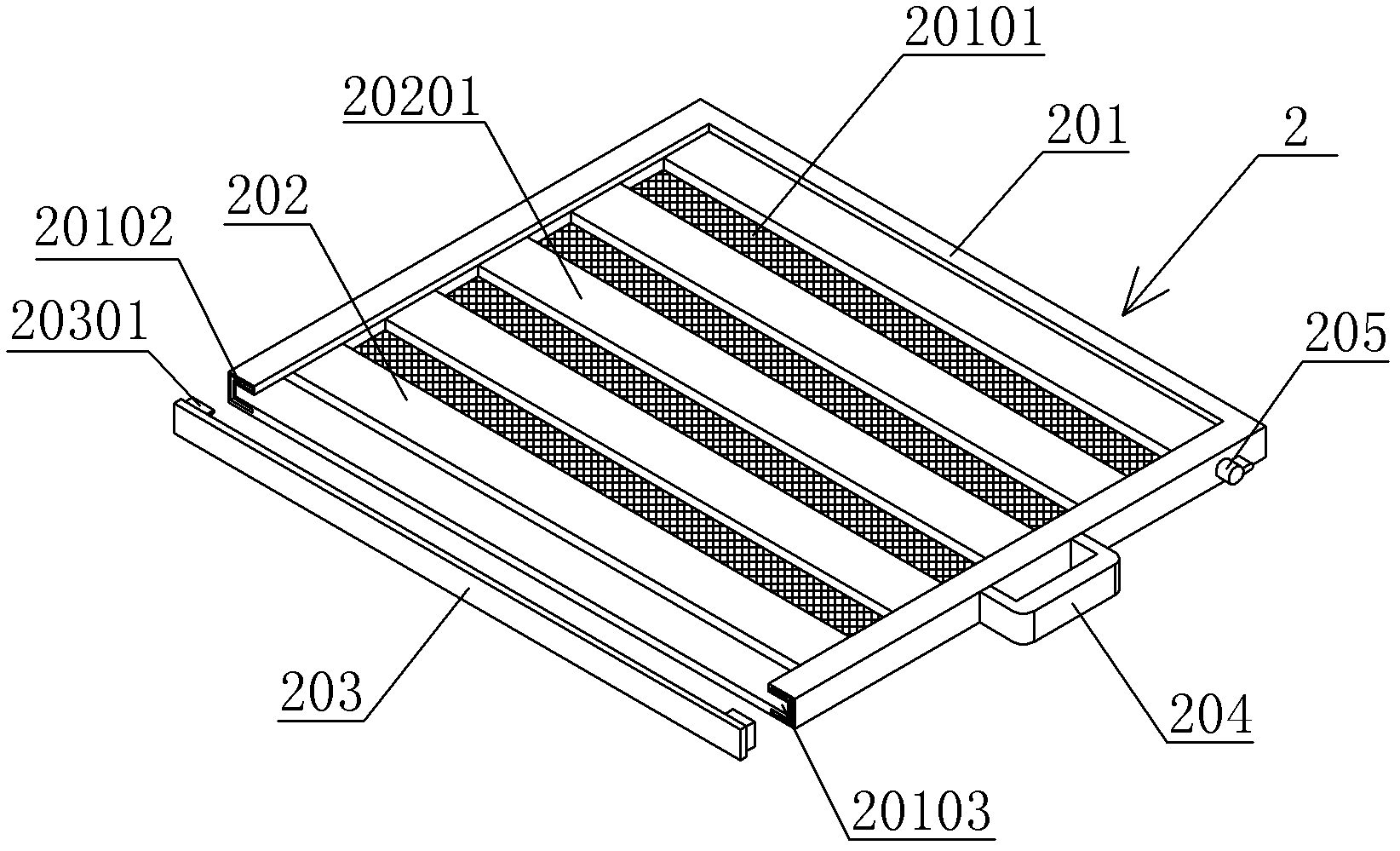

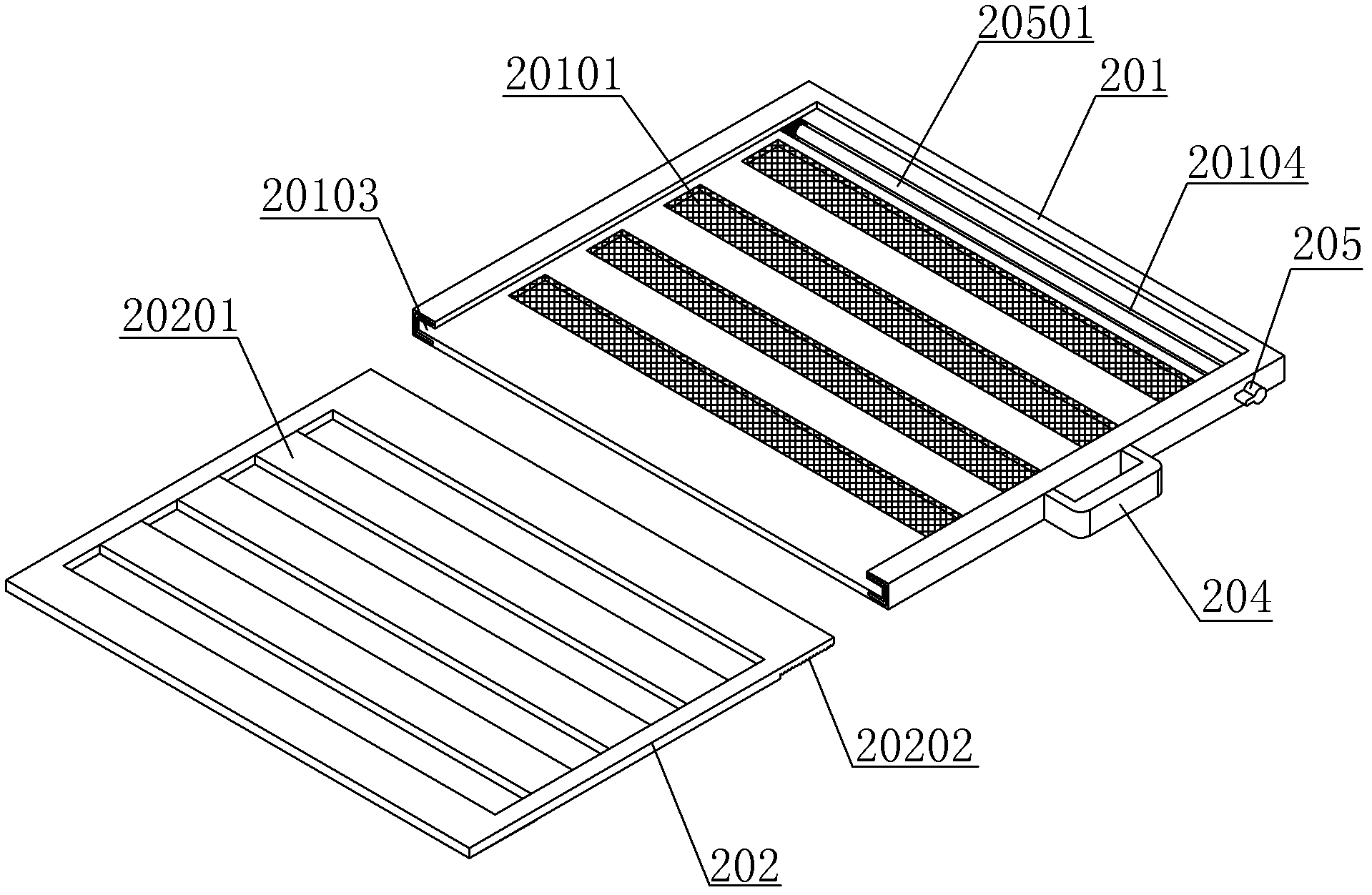

[0022] Such as figure 1 As shown, the environment-friendly water and oil automatic separation tank includes a tank body 1, a drawer-type filter layer 2, and a water-oil separation box. Floor. The upper end of the water-oil separation box is provided with a diversion and converging device, and the diversion and converging device is composed of two inclined slide plates 3, and a converging port is formed between the two slide plates. Wherein the bottom of the slide plate on the right side is fixed with a layered partition 7, and the layered partition divides the water-oil separation box into an oil overflow chamber 6 and a water outlet chamber 8, namely figure 1 The left side of the middle layer partition is the oil overflow chamber, and the right side is the water outlet chamber. In the oil spill chamber, an oil outlet 5 is provided on the upper side, and a horizontally ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com