Method for removing impurities through directional solidification with electron beam inducing

An electron beam-induced, directional solidification technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as inability to remove, reduce process links, facilitate large-scale popularization and application, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

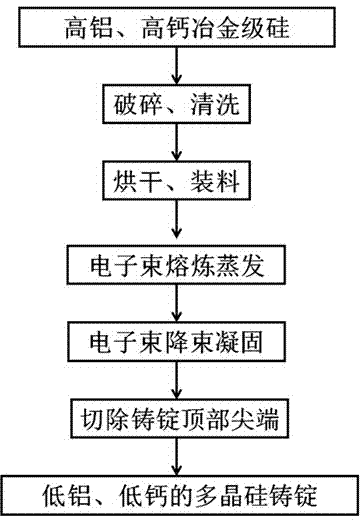

Image

Examples

Embodiment 1

[0021] (1) Retrieving and pretreatment: Select metallurgical grade silicon with an impurity aluminum content of 103ppmw and a calcium content of 42ppmw as raw material, wherein the mass fraction of silicon is 98.5%, break the raw material into small pieces, and place them in analytical pure alcohol for ultrasonication Vibration cleaning to remove residual oil and dust on the surface; the cleaned silicon material is placed in a water-cooled copper crucible in an electron beam melting furnace after drying; the furnace is vacuumed to 1.2 by mechanical pump, Roots pump and diffusion pump ×10-2Pa;

[0022] (2) Evaporation and impurity removal by electron beam smelting: Start the electron gun, set the high voltage to 30kV, and bombard the surface of the polysilicon material with a beam current of 700mA. The state bombards the surface of the silicon material to ensure that the silicon material is heated evenly and stably. Through the observation window, it can be clearly observed tha...

Embodiment 2

[0025] (1) Retrieving and pretreatment: Select metallurgical grade silicon with an impurity aluminum content of 98ppmw and a calcium content of 36ppmw as raw materials, in which the mass fraction of silicon is 99.2%, break the raw materials into small pieces, and place them in analytical pure alcohol for ultrasonication Vibration cleaning to remove residual oil and dust on the surface; the cleaned silicon material is placed in a water-cooled copper crucible in an electron beam melting furnace after drying; the furnace is vacuumed to 1.4 by mechanical pump, Roots pump and diffusion pump ×10-2Pa;

[0026] (2) Evaporation and impurity removal by electron beam smelting: start the electron gun, set the high voltage to 30kV, and bombard the surface of the polysilicon material with a beam current of 600mA. The state bombards the surface of the silicon material to ensure that the silicon material is heated evenly and stably. Through the observation window, it can be clearly observed t...

Embodiment 3

[0029](1) Retrieving and pretreatment: Select metallurgical grade silicon with an impurity aluminum content of 67ppmw and a calcium content of 28ppmw as raw material, in which the mass fraction of silicon is 99.5%, break the raw material into small pieces, and place them in analytical pure alcohol for ultrasonication Vibration cleaning to remove residual oil and dust on the surface; the cleaned silicon material is placed in a water-cooled copper crucible in an electron beam melting furnace after drying; the furnace is vacuumed to 1.1 by mechanical pump, Roots pump and diffusion pump ×10-2Pa;

[0030] (2) Evaporation and impurity removal by electron beam smelting: start the electron gun, set the high voltage to 30kV, and bombard the surface of the polysilicon material with a beam current of 600mA. The state bombards the surface of the silicon material to ensure that the silicon material is heated evenly and stably. Through the observation window, it can be clearly observed that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com