Method and device for coupling and purifying polysilicon and removing phosphorus and metal with electron beams

A polysilicon and electron beam technology, applied in non-metallic elements, chemical instruments and methods, silicon compounds, etc., can solve the problems of high energy consumption and uneven distribution of impurities, and achieve the effects of energy saving, low cost and fast removal speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for the coupled purification of polysilicon by electron beam dephosphorization and metal removal. First, a stable molten pool is formed on the top of a low-phosphorus, low-metal high-purity silicon ingot through an electron beam, and then the silicon powder to be purified is dropped into the molten pool for melting , realize rapid melting of powder to remove volatile impurity phosphorus in silicon powder, and at the same time carry out directional ingot pulling to enable directional solidification and growth of low-phosphorus polysilicon, and remove metal impurities in polysilicon through segregation effect. The specific steps are as follows:

[0022] The first step of material preparation: use low-phosphorus, low-metal high-purity silicon ingots in vacuum equipment as carriers, and put high-phosphorus and high-metal powder silicon materials that need to be purified into powder buckets on top of them;

[0023] The second step of pretreatment: vacuumize the vacuu...

Embodiment 2

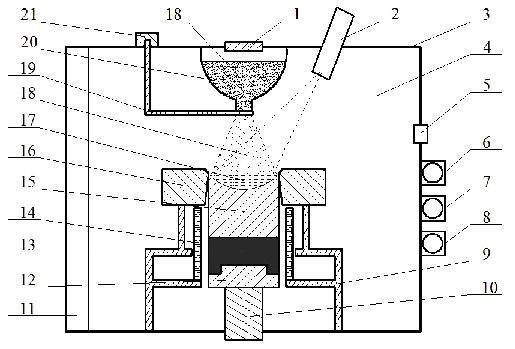

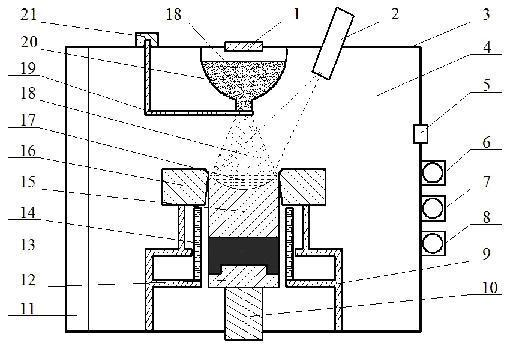

[0026] Such as figure 1The equipment used in the coupling purification method of polysilicon by electron beam dephosphorization and metal removal is shown. The equipment adopts a vacuum cover 11, a vacuum furnace wall 3 and a powder filling cover 1 to form a vacuum equipment, and the inner chamber of the vacuum equipment is a vacuum chamber 4; The upper part of the vacuum chamber is equipped with a powder loading bucket, the top of the powder loading bucket is equipped with a powder loading cover, the powder loading cover is located on the vacuum furnace wall, the bottom of the powder loading bucket has a discharge port, and the discharge port is equipped with an externally driven powder baffle. The externally driven powder baffle is an L-shaped powder baffle. One end of the powder baffle is rotated and installed in the rotating mechanism. The rotating mechanism is installed outside the vacuum furnace wall. A crucible is installed at the bottom of the outlet of the powder loadi...

Embodiment 3

[0028] Adopt the equipment described in embodiment 2 to carry out the method for the coupling purification polysilicon of electron beam dephosphorization, metal removal, specifically:

[0029] The first step of material preparation: put the low-phosphorus, low-metal high-purity silicon ingot 15 with a phosphorus content of 0.00004% and a total metal content of 0.0002% on the graphite block 8, and the top of the low-phosphorus, low-metal high-purity silicon ingot 15 is connected with the water-cooled copper The upper surface of the annular crucible 16 should be horizontal, and the powder baffle plate 19 should be rotated to the bottom of the powder loading bucket 20 by the rotating mechanism 21 to block the powder falling hole at the bottom of the powder loading bucket 20, and open the powder loading cover 1 to the powder loading bucket 20 Add phosphorus content 0.003%, metal impurity total content 0.01% high phosphorus, high metal silicon powder 18, high phosphorus, high metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com