Concrete water-retention anti-segregation agent and preparation method thereof

An anti-segregation agent and concrete technology, applied in the field of concrete admixtures, can solve problems such as use restrictions, and achieve the effects of improving workability, avoiding mildew and compatibility, and being easy to popularize in large areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

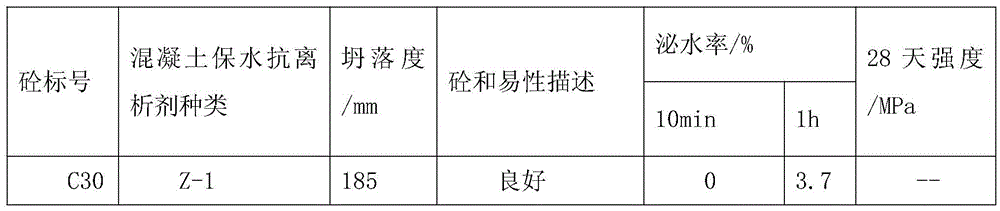

Embodiment 1

[0023] Embodiment 1: Preparation of concrete water-retaining anti-segregation agent

[0024] Add 300 parts of TPEG, 100 parts of acrylamide, 5 parts of vinyltrimethylsilane and 1250 parts of deionized water into the reactor. After stirring for 10 minutes, 4.3 parts of potassium persulfate were added in one go. Then, under the condition of constant stirring, a mixed solution of 3 parts of sodium hydrogen sulfoxylate formaldehyde, 1.5 parts of tertiary dodecylmercaptan and 250 parts of deionized water was added dropwise, and the dripping was completed within 1 to 4 hours. After dripping, stir for another 1-3 hours, then add liquid caustic soda into the reaction kettle, adjust the final pH to 6-10, and obtain the water-retaining anti-segregation agent. Record the sample as Z-1.

Embodiment 2

[0025] Example 2: Preparation of concrete water retention and anti-segregation agent

[0026] Add 300 parts of TPEG, 100 parts of acrylamide, 12.5 parts of γ-methacryloxypropyltrimethoxysilane and 1500 parts of deionized water into the reaction kettle. After stirring for 10 minutes, 3.6 parts of ammonium persulfate were added in one go. Then, under the condition of constant stirring, a mixed solution of 1 part of ascorbic acid, 1 part of thioglycolic acid and 300 parts of deionized water was added dropwise, and the drop was completed within 1 to 4 hours. After dripping, stir for another 1-3 hours, then add liquid caustic soda into the reaction kettle, adjust the final pH to 6-10, and obtain the water-retaining anti-segregation agent. Record the sample as Z-2.

Embodiment 3

[0027] Example 3: Preparation of concrete water retention and anti-segregation agent

[0028] 130.4 parts of TPEG, 78 parts of acrylamide, 3.9 parts of γ-methacryloxypropyltrimethoxysilane and 1800 parts of deionized water were added to the reaction kettle. After stirring for 10 minutes, 3 parts of ammonium persulfate were added in one go. Then, under the condition of constant stirring, a mixed solution of 2.6 parts of sodium bisulfite formaldehyde, 22 parts of acrylic acid, 1.5 parts of octyl mercaptan and 360 parts of deionized water was added dropwise, and the dripping was completed within 1 to 4 hours. After dripping, stir for another 1-3 hours, then add liquid caustic soda into the reaction kettle, adjust the final pH to 6-10, and obtain the water-retaining anti-segregation agent. Record the sample as Z-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com