Polycarboxylene high-performance water reducing agent and preparation method thereof

A technology of polycarboxylate and water reducer, applied in the preparation of the polycarboxylate high performance water reducer, in the field of polycarboxylate high performance water reducer, can solve the problem of singleness of polycarboxylate products, adaptability Sexual stenosis and other problems, to achieve the effect of convenient application, lower cost, and improved properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

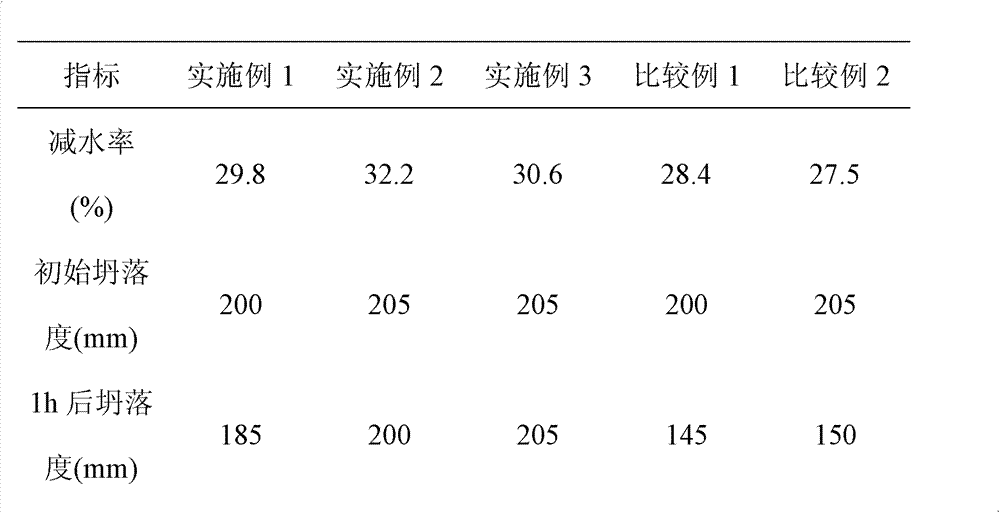

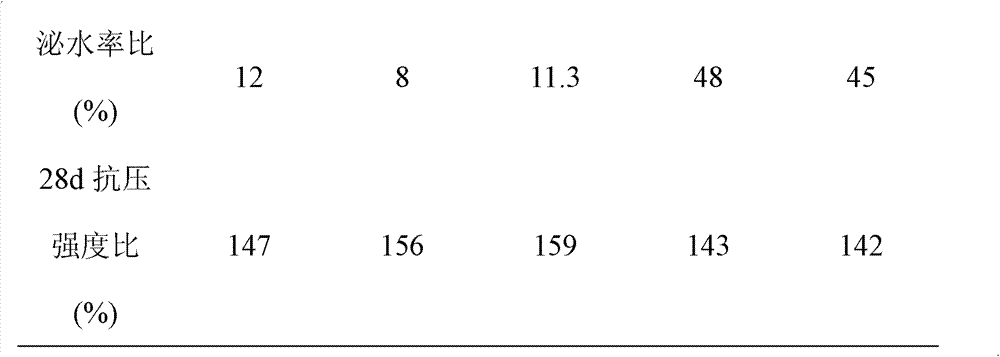

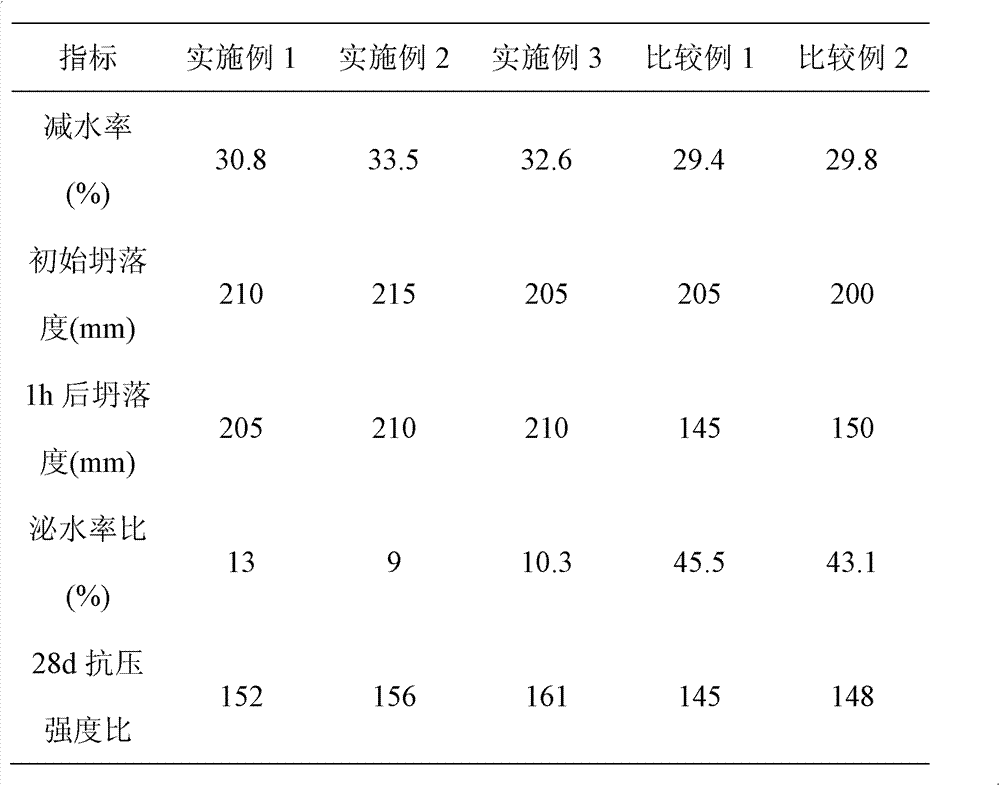

Examples

Embodiment 1

[0062] Add 2200g of MPEG (molecular weight: 1200) into a 3000ml flask and heat up to 70°C. After it is completely dissolved, add 0.40g of polymerization inhibitor phenothiazine and 2g of hydroquinone, stir for 2 to 3 minutes, and then add 438g of methacrylic acid. After stirring for 2-3 minutes, add 41g of concentrated sulfuric acid, raise the temperature to 120±5°C and keep it warm for 6 hours, and after keeping it warm for 1.5 hours, start filling with nitrogen for 3 hours to dehydrate to improve the esterification rate, and cool down to below 70°C to generate MPEGMAA.

[0063] Add 1600g of APEG and 1000g of deionized water into a 5000ml flask, raise the temperature to 60°C, add 110g of hydrogen peroxide diluted to 2% after the APEG is completely dissolved, mix material A (water 580g+AA200g+SA9.8g) and material B (MPEGMAA180g+water 120g) for 3 hours After uniform dropwise addition, keep warm at 60°C-65°C for 2 hours, cool down to 45°C, add 30% NaOH to adjust the pH value to a...

Embodiment 2

[0065] MPEGMAA was prepared in the same manner as in Example 1.

[0066] Add 1500g of APEG, 15g of MA and 950g of deionized water into a 5000ml flask, raise the temperature to 60°C, add 110g of hydrogen peroxide diluted to 2% after the APEG is completely dissolved, mix A material (water 580g+AA190g+SA9. ) after 3 hours of uniform dropwise addition, keep warm at 60°C-65°C for 2h, cool down to 45°C, add 30% NaOH to adjust the pH value to about 6.5, and finally add water to adjust the product to 40% and store it for later use.

Embodiment 3

[0068] MPEGMAA was prepared in the same manner as in Example 1.

[0069] Add 1400g of APEG, 25g of MA and 950g of deionized water into a 5000ml flask, raise the temperature to 60°C, add 110g of hydrogen peroxide diluted to 2% after the APEG is completely dissolved, mix material A (water 580g+AA180g+SA8. ) after 3 hours of uniform dropwise addition, keep warm at 60°C-65°C for 2h, cool down to 45°C, add 30% NaOH to adjust the pH value to about 6.5, and finally add water to adjust the product to 40% and store it for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com