Segregation type centrifugal material screening and grading technology and special device thereof

A kind of material sieving and centrifugal technology, which is applied in the direction of sieving, solid separation, grille, etc., can solve the problems that affect the output and sieving efficiency of the sieving machine, it is difficult to achieve the layering effect, and the particles are difficult to separate, etc. High efficiency, low noise and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

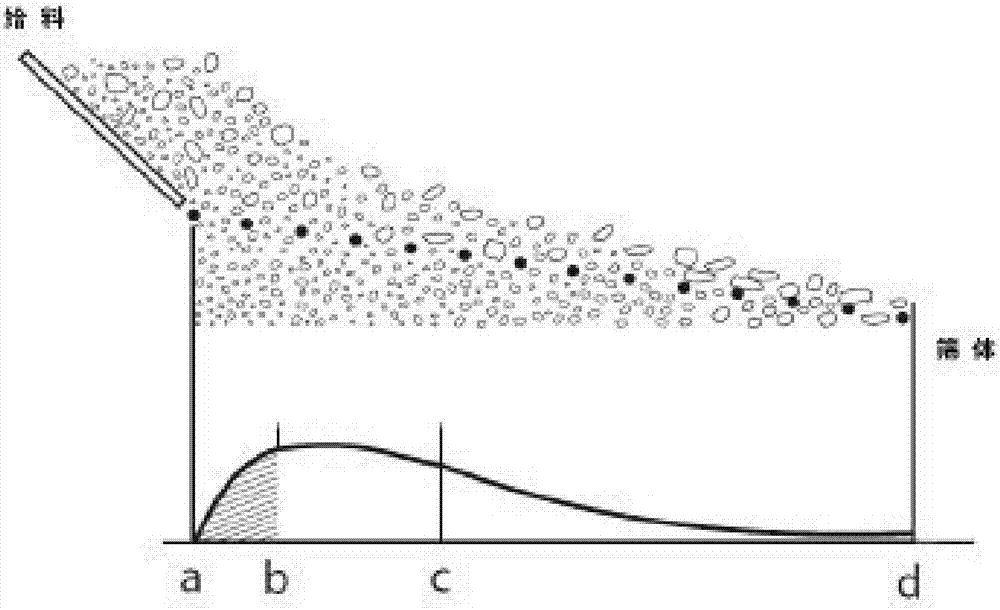

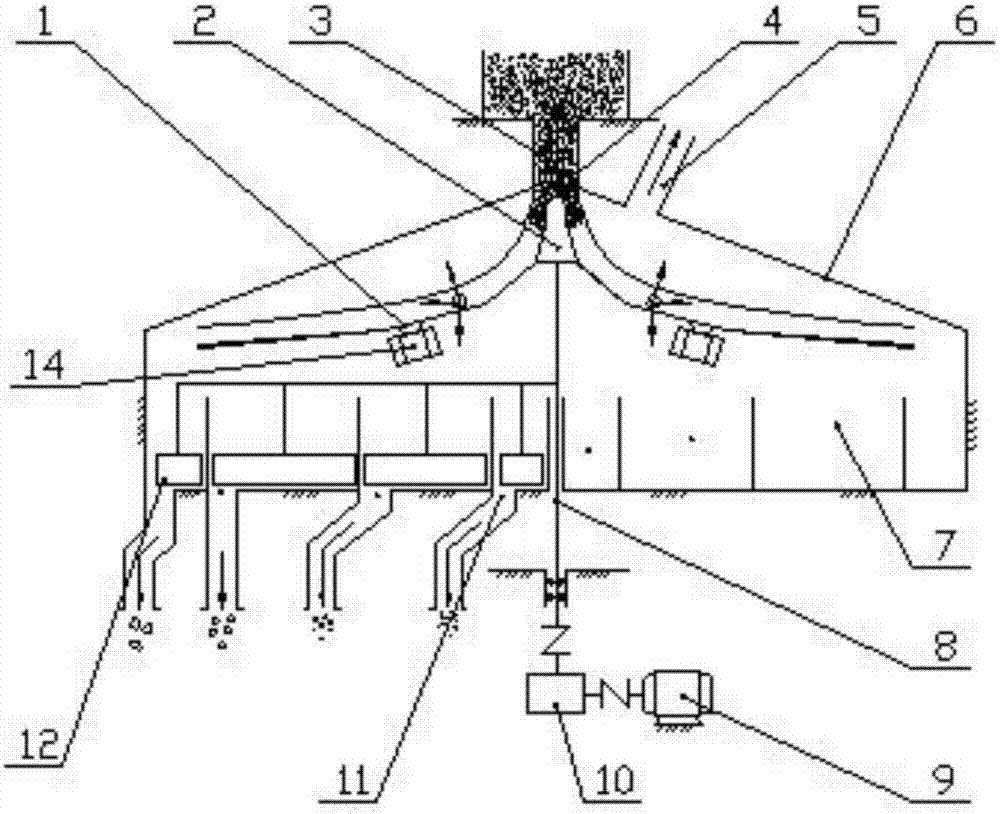

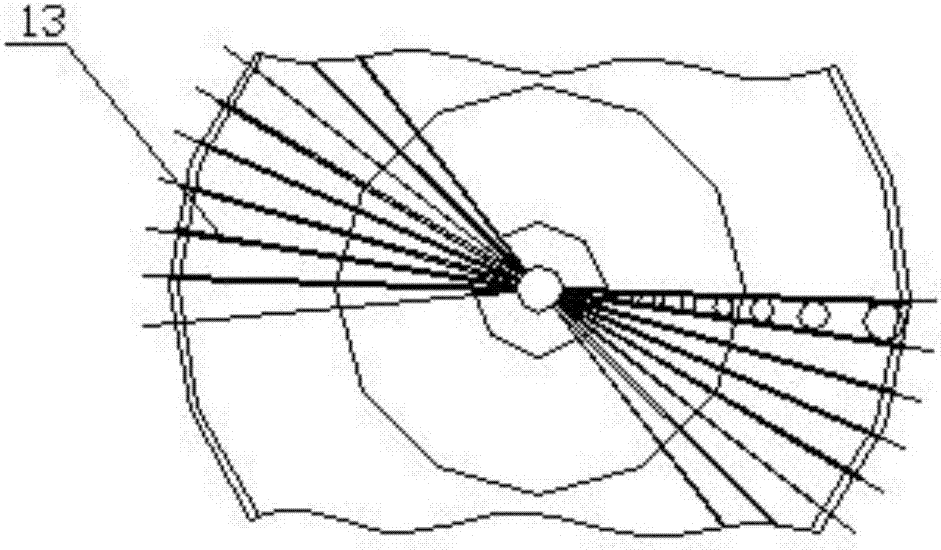

[0016] Example: see attached figure 1 , 2 , 3, 4, segregation centrifugal material screening and grading process, the material is fed from the feeding cylinder 4 above the center of the sieve, and the material is evenly fed to the screen surface through the screw feeding device 3 on the top of the feeding cone 2, and the material leaves the feeder After the barrel 4, under the action of gravity, the material is evenly divided by the feeding cone 2, and then falls to the screen surface 1. The material is firstly separated under the action of the segregation effect, and the particles (r) of different particle sizes are initially stratified, and the smaller particles Accumulated around the center of the screen surface, the larger particles are farther away from the center; at the same time, because the gap B (sieve gap) of the radial screen bar 13 is getting wider and wider from the center to the outside, the small particle materials first pass through the narrower screen gap nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com