Concrete anti-segregation method

A concrete and anti-segregation technology, applied in the field of concrete, can solve the problems affecting the construction performance of concrete pumping, reducing economic benefits, and affecting the construction period, etc., to achieve the effects of improving conveying performance and construction performance, reducing labor intensity, and no pollution residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Source of raw materials: The cement is 42.5-grade ordinary Portland cement produced by Guizhou Taiwan Cement, and its performance meets the requirements of GB175-2007; the methylene blue value of the sand is 1.2, the fineness modulus is 2.9, the gradation area is the second area, and the gravel It is a continuous gradation of 5-31.5mm, and the fly ash is selected as the secondary ash of Jinsha Power Plant. Polyacrylamide with a molecular weight of 2.5 million.

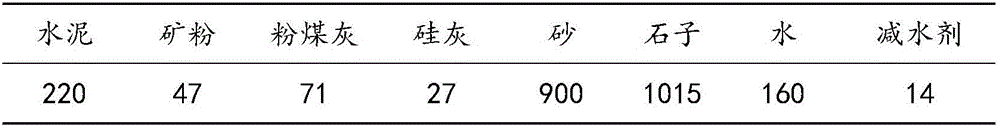

[0013] The mix ratio of C30 segregated concrete is shown in Table 1: the polycarboxylate superplasticizer is overmixed.

[0014] Table 1 per 1m 3 The mass of each raw material of segregated concrete (unit: kg)

[0015]

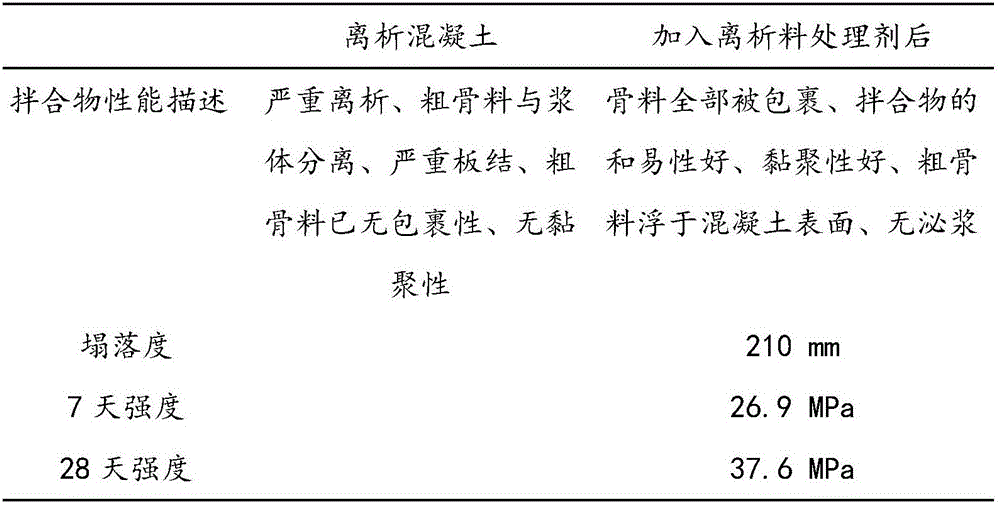

[0016] Add 4.4kg of cement, 1.42kg of fly ash, 0.92kg of mineral powder, 0.54kg of silica fume, 18kg of sand, 20.3kg of gravel, 6.2kg of water, and 280g of polycarboxylate superplasticizer into a concrete mixer with a capacity of 60L and stir for 4 minutes. After the concrete stays in the ...

Embodiment 2

[0020] The source of raw materials is the same as in Example 1.

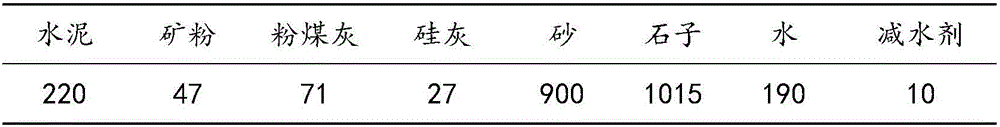

[0021] The mix ratio of C30 segregated concrete is shown in Table 3: too much water is added.

[0022] Table 3 per 1m 3 The mass of each raw material of segregated concrete (unit: kg)

[0023]

[0024] Add 4.4kg of cement, 1.42kg of fly ash, 0.92kg of mineral powder, 0.54kg of silica fume, 18kg of sand, 20.3kg of stone, 6.2kg of water, and 210g of polycarboxylate superplasticizer into a concrete mixer with a capacity of 60L and stir for 4 minutes. After the concrete stayed in the mixer for 0.5 hours, its properties were described in Table 2. After that, 1.0 g of polyacrylamide was added, stirred for 2 minutes, poured out, and the properties of the mixture were measured. The properties are shown in Table 4.

[0025] Table 4 Performance description of concrete before and after segregation treatment

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com