Method for improving copper oxidation resistance of authigenic nonmetal oxide composite film

A technology of non-metallic oxide and anti-oxidation ability, applied in the field of self-generated non-metallic oxide composite film to improve the anti-oxidation ability of copper, can solve the problems of copper-based products being easily corroded, affecting copper performance, use restrictions, etc., to improve the anti-oxidation ability. Effects of oxidizing power, improving oxidation resistance, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

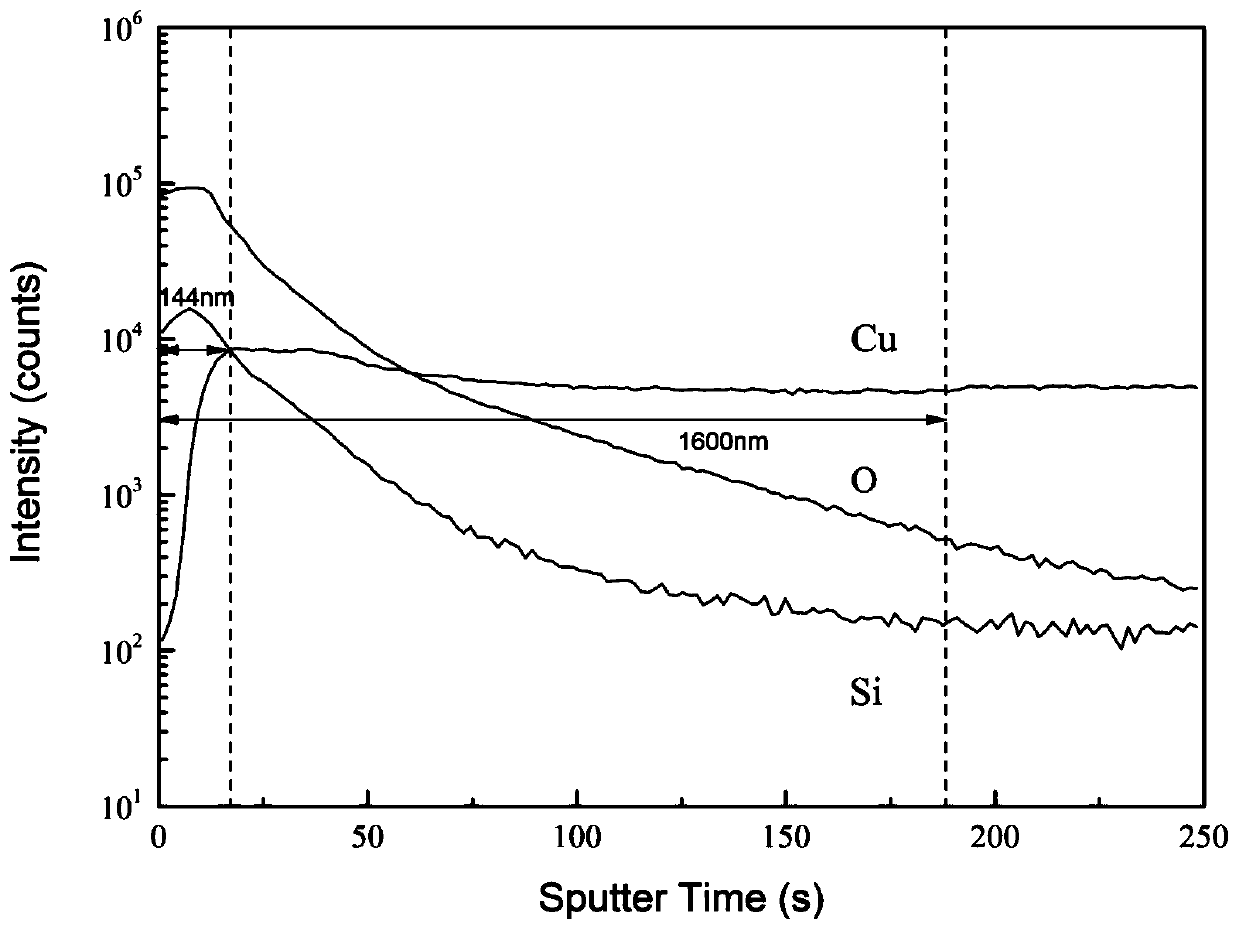

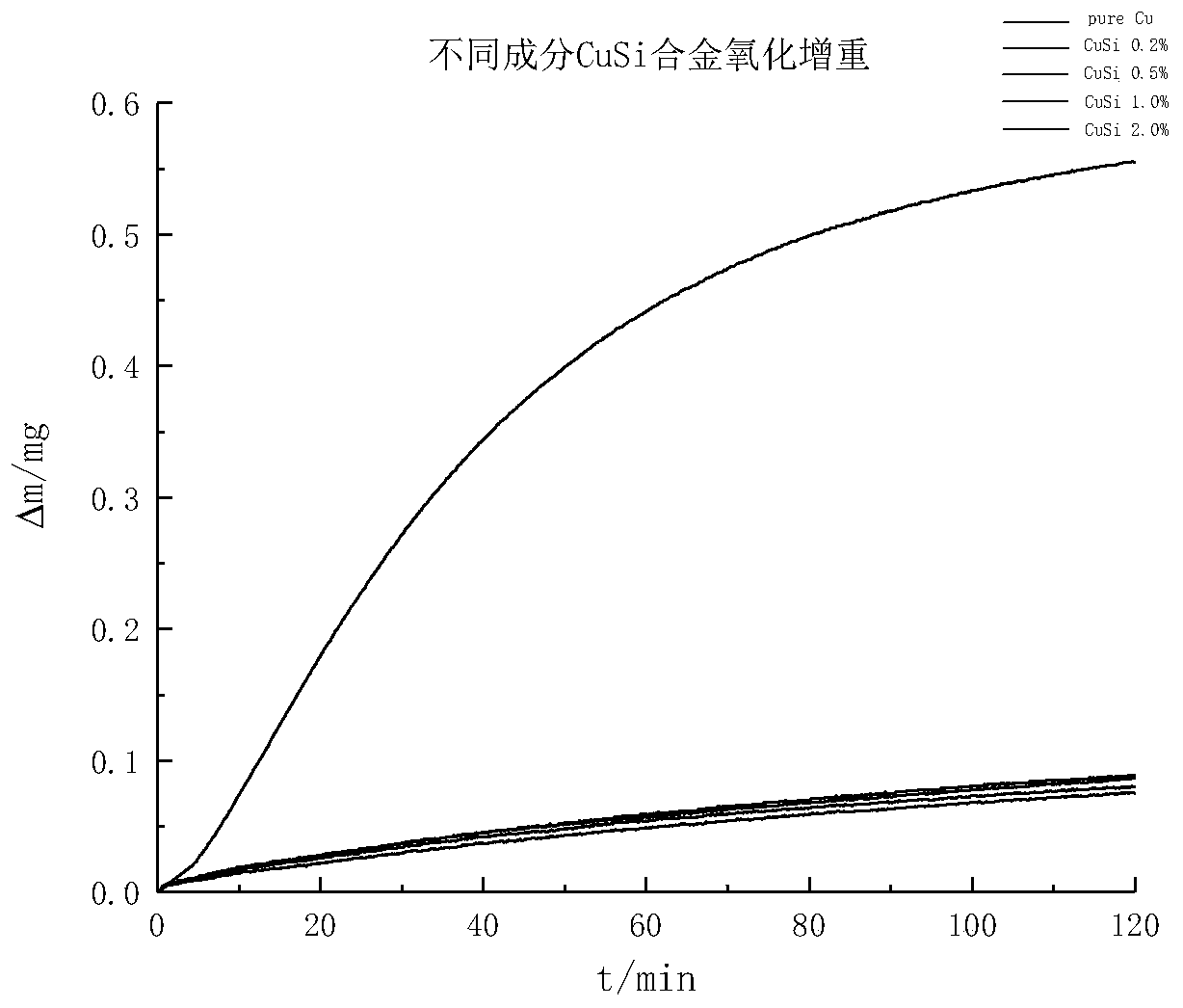

Image

Examples

Embodiment 1

[0031] a. being that 0.2% Si with a granular mass fraction of a purity of 99.99% is mixed with pure Cu with a granular mass fraction of 99.8% and a purity of 99.9999%;

[0032] b. Put the mixed materials in three different crucibles on the melting plate of the vacuum melting furnace, and put the titanium ingot (standard deoxidized sample) in the crucible in the center of the melting plate, and then pump the furnace to a low vacuum (-0.1 atm). Introduce high-purity argon, the flow rate of high-purity argon is 3000-6000cm 3 / min, the air pressure is 1atm, and the ventilation is repeated 3-5 times to ensure the argon protective gas environment in the vacuum melting furnace;

[0033] c. Turn on the welding machine, the welding machine adopts WS-IGBT manual tungsten argon arc welding machine, start the welding torch located in the vacuum melting furnace, point the welding torch at the crucible with titanium ingot in the center of the melting plate of the vacuum melting furnace, an...

Embodiment 2

[0038] a. be 0.5% Si with a purity of 99.99% and a granular mass fraction of 99.5% pure Cu mixed with a mass fraction of 99.9999%;

[0039] b. Put the mixed materials in three different crucibles on the melting plate of the vacuum melting furnace, and put the titanium ingot (standard deoxidized sample) in the crucible in the center of the melting plate, and then pump the furnace to a low vacuum (-0.1 atm). Introduce high-purity argon, and the flow rate of high-purity argon is 3000-6000cm 3 / min, the air pressure is 1atm, and the ventilation is repeated 3-5 times to ensure the argon protective gas environment in the vacuum melting furnace;

[0040] c. Turn on the welding machine, the welding machine adopts WS-IGBT manual tungsten argon arc welding machine, start the welding torch located in the vacuum melting furnace, point the welding torch at the crucible with titanium ingot in the center of the melting plate of the vacuum melting furnace, and repeatedly smelt titanium Ingo...

Embodiment 3

[0045] a. being 99.99% Si with a granular mass fraction of 1% purity and 99% pure Cu with a granular mass fraction of 99%; Put the titanium ingot (standard deoxidized sample) in the crucible in the center of the melting plate, and then pump the furnace to a low vacuum (-0.1atm). Introduce high-purity argon, and the flow rate of high-purity argon is 3000-6000cm 3 / min, the air pressure is 1atm, and the ventilation is repeated 3-5 times to ensure the argon protective gas environment in the vacuum melting furnace;

[0046] c. Turn on the welding machine, the welding machine adopts WS-IGBT manual tungsten argon arc welding machine, start the welding torch located in the vacuum melting furnace, point the welding torch at the crucible with titanium ingot in the center of the melting plate of the vacuum melting furnace, and repeatedly smelt titanium Ingot 8-10 times, each time 40-60s, current 3-5A, to remove possible residual oxygen in the vacuum melting furnace, to prevent the form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com