Preparing method for high-activity and high-stability composite catalyst for fuel cells

A composite catalyst and high-stability technology, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., to achieve the effects of inhibiting migration and agglomeration growth, improving stability, and facilitating popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

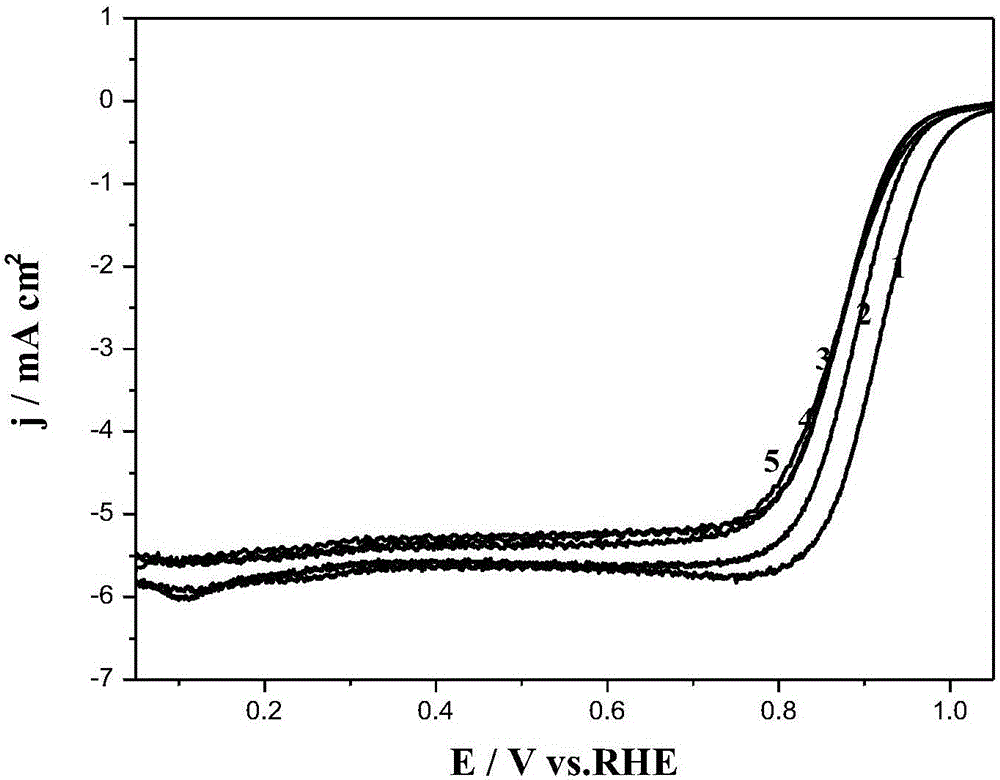

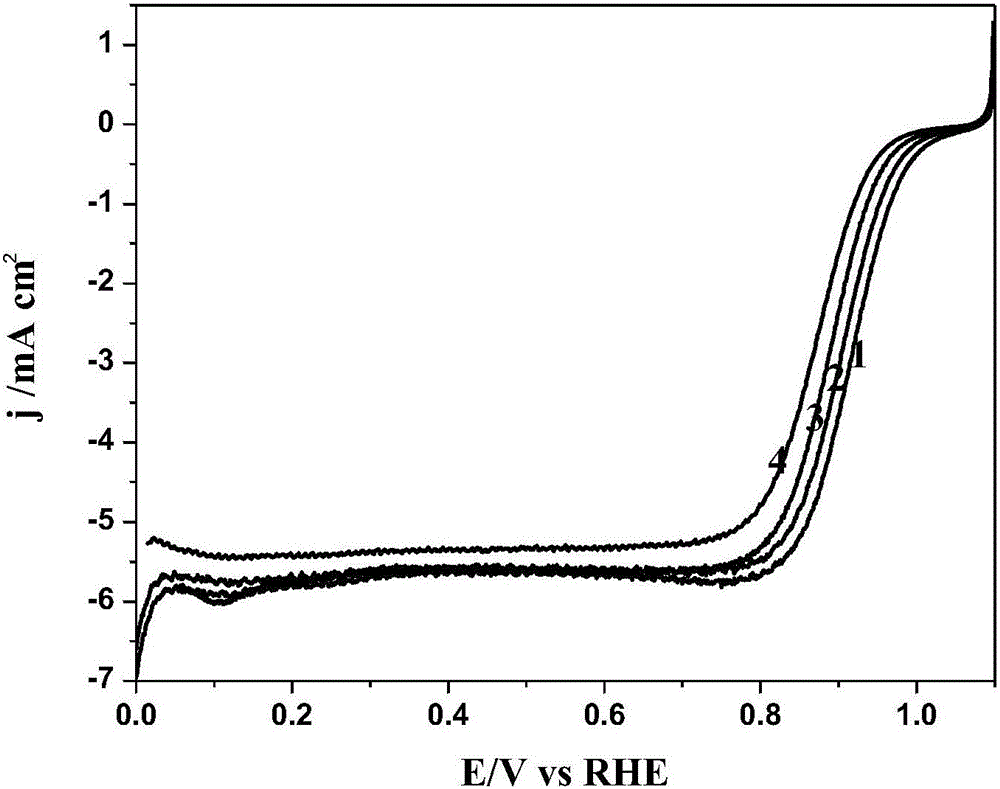

Examples

Embodiment 1

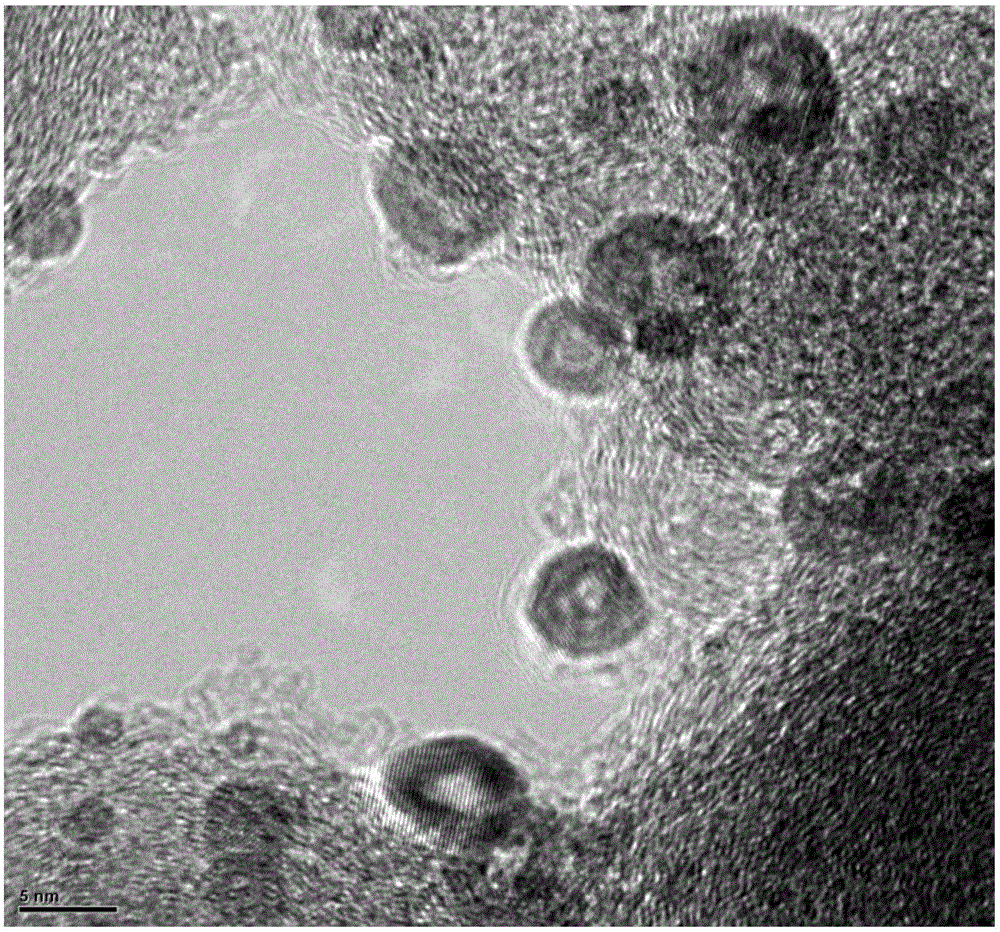

[0032] A method for preparing a high-activity and high-stability fuel cell composite catalyst, the specific method steps comprising:

[0033] (1) In situ polymerization of dopamine and adsorption of iron ions

[0034] First, the Pt / C catalyst and dopamine are weighed according to the mass ratio of the Pt / C catalyst and dopamine in the ratio of 1:0.7, and then the mixed solution with the volume ratio of ethanol and water of 1:1 is used as a solvent to control the concentration of the solution. The mass concentration of the Pt / C catalyst is 0.1 mg / ml, and the prepared solution is ultrasonicated for 10 minutes to uniformly disperse the Pt / C catalyst, and then the mass ratio of Tris-HCl to dopamine is 1:1. HCl buffer solution, stirred and polymerized at 30°C for 2 hours, centrifuged and washed the stirred sample with deionized water several times, then added ferric chloride according to the molar ratio of Pt and ferric chloride at 1:1, and stirred for 2 hours Make it fully absorb...

Embodiment 2

[0044] A method for preparing a high-activity and high-stability fuel cell composite catalyst, the specific method steps comprising:

[0045] (1) In situ polymerization of dopamine and adsorption of iron ions

[0046] First, weigh the Pt / C catalyst and dopamine according to the mass ratio of the Pt / C catalyst and dopamine in the ratio of 1:3, and then use the mixed solution with the volume ratio of ethanol and water as 1:3 as the solvent to control the concentration of the solution. Make the mass concentration of the Pt / C catalyst 0.1 mg / ml, ultrasonic the prepared solution for 60 minutes to uniformly disperse the Pt / C catalyst, then add Tris- HCl buffer solution, stirred and polymerized at 0°C for 2 hours, centrifuged and washed the stirred sample several times with deionized water, then added ferric nitrate according to the molar ratio of Pt and ferric nitrate at 1:1, and stirred for 2 hours to make it Fully absorb iron ions.

[0047] (2) Encapsulation and confinement of p...

Embodiment 3

[0054] A method for preparing a high-activity and high-stability fuel cell composite catalyst, the specific method steps comprising:

[0055] (1) In situ polymerization of dopamine and adsorption of cobalt ions

[0056] First, weigh the Pt / C catalyst and dopamine according to the mass ratio of the Pt / C catalyst and dopamine in the ratio of 1:3, and then use the mixed solution with the volume ratio of ethanol and water as 1:3 as the solvent to control the concentration of the solution. The mass concentration of the Pt / C catalyst is 2 mg / ml, and the prepared solution is ultrasonicated for 60 minutes to uniformly disperse the Pt / C catalyst, and then the mass ratio of Tris-HCl to dopamine is 1:3 by adding Tris- HCl buffer solution, stirred and polymerized at 30°C for 24 hours, centrifuged and washed the stirred sample several times with deionized water, then added cobalt nitrate according to the molar ratio of Pt and cobalt nitrate at 1:5, and stirred for 24 hours to make it Full...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com