GaN-based Single chip white light emitting diode epitaxial material

A technology of light-emitting diodes and epitaxial materials, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of not being practical, and the white light luminous efficiency of GaN-based white light-emitting diodes is not high enough, so as to reduce dislocations and improve light utilization Efficiency, simplification of the production process and the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

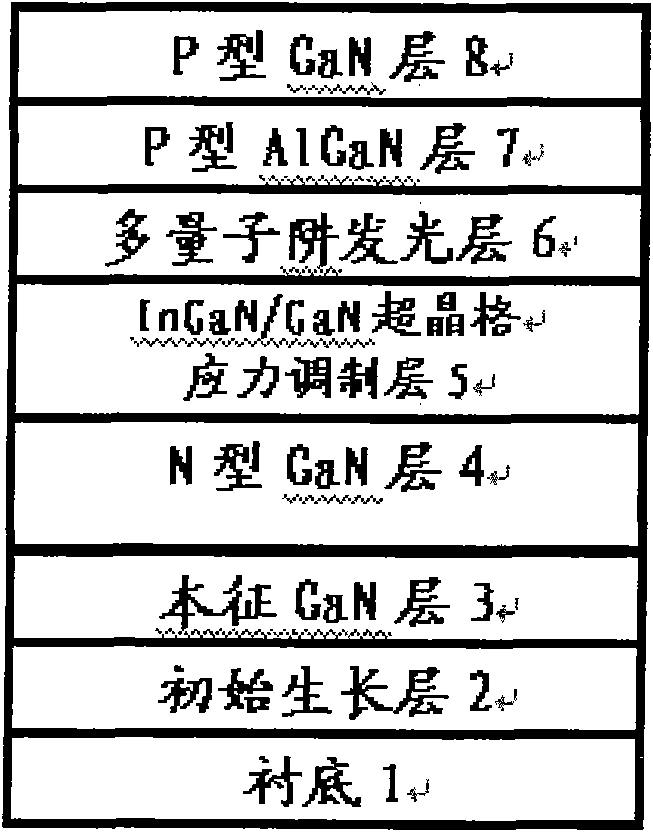

[0030] refer to figure 1 , making a GaN-based single-chip white light-emitting diode epitaxial material of the present invention, its structure is as follows:

[0031] Using sapphire as the substrate 1, a 20nm thick GaN initial growth layer 2, a 200nm intrinsic GaN layer 3, and a 1 μm thick n-type GaN layer 4 (doped Concentration 5×10 18 cm -3 ), 20 cycles of 10nm thick (referring to In 0.1 Ga 0.9 N monolayer thickness) In 0.1 Ga 0.9 N / 10nm thick GaN superlattice stress modulation layer 5, InGaN multi-quantum structure light-emitting layer 6 (composed of barrier layer In 0.05 Ga 0.95 N and quantum well layer In 0.15 Ga 0.85 5 periods of multiple quantum wells composed of N, in which the barrier layer In 0.05 Ga 0.95 The thickness of N is 10nm, the quantum well layer In 0.15 Ga 0.85 N thickness is 3nm), 100nm thick p-type Al 0.2 Ga 0.8 N interlayer 7, 100nm thick p-type GaN layer 8 (doping concentration 3×10 17 cm -3 ), to obtain the GaN-based single-chip white...

Embodiment 2

[0033] refer to figure 1 , make a GaN-based single-chip white light-emitting diode epitaxial material of the present invention: adopt 0.4mm thick SiC as the substrate 1, use metal organic chemical vapor deposition technology (MOCVD) to sequentially grow 100nm thick AlN initial growth on it Layer 2, 0.3 μm thick intrinsic GaN layer 3, 1 μm thick n-type GaN layer 4, 150 nm thick 10 periods of 5 nmIn 0.15 Ga 0.85 N / 10nm thick In 0.05 Ga 0.95 N superlattice stress modulation layer 5, InGaN multi-quantum structure light-emitting layer 6 (composed of barrier layer GaN and quantum well layer In 0.15 Ga 0.85 4 periods of multiple quantum wells composed of N, in which the thickness of the barrier layer GaN is 12nm, and the quantum well layer In 0.15 Ga 0.85 The thickness of N is 3 nm, and the doping concentration of GaN in the barrier layer is 1×10 18 / cm 3 , the doping concentration of the quantum well layer InxGa1-xN layer is 0), 50nm thick p-type Al 0.2 Ga 0.8 N interlayer...

Embodiment 3

[0035] refer to figure 1 , making a GaN-based single-chip white light-emitting diode epitaxial material of the present invention: a 0.3mm thick silicon substrate is used as the substrate 1, and a 200nm thick AlN initial growth layer 2 is sequentially grown on it by molecular beam epitaxy (MBE) , 0.5 μm thick intrinsic GaN layer 3, 0.5 μm thick n-type GaN layer 4, 15 cycles of 1nm In 0.3 Ga 0.7 N / 8nm In 0.05 al 0.02 Ga 0.93 N superlattice stress modulation layer 5, InGaN multi-quantum structure light-emitting layer 6 (composed of barrier layer GaN and quantum well layer In 0.15 Ga 0.85 4 periods of multiple quantum wells composed of N, in which the thickness of the barrier layer GaN is 10nm, and the quantum well layer In 0.15 Ga 0.85 The thickness of N is 3 nm, and the doping concentration of GaN in the barrier layer is 1×10 17 / cm 3 , the quantum well layer In x Ga 1-x The doping concentration of the N layer is 2×10 17 / cm 3 ), 100nm thick p-type Al 0.2 Ga 0.8 N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com