Material segregation apparatus for blast furnace top bunker

A raw material silo and raw material technology, applied in the field of raw material silo, can solve the problems of raw material segregation effect limit and length limitation, and achieve the effect of improving raw material segregation effect and avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

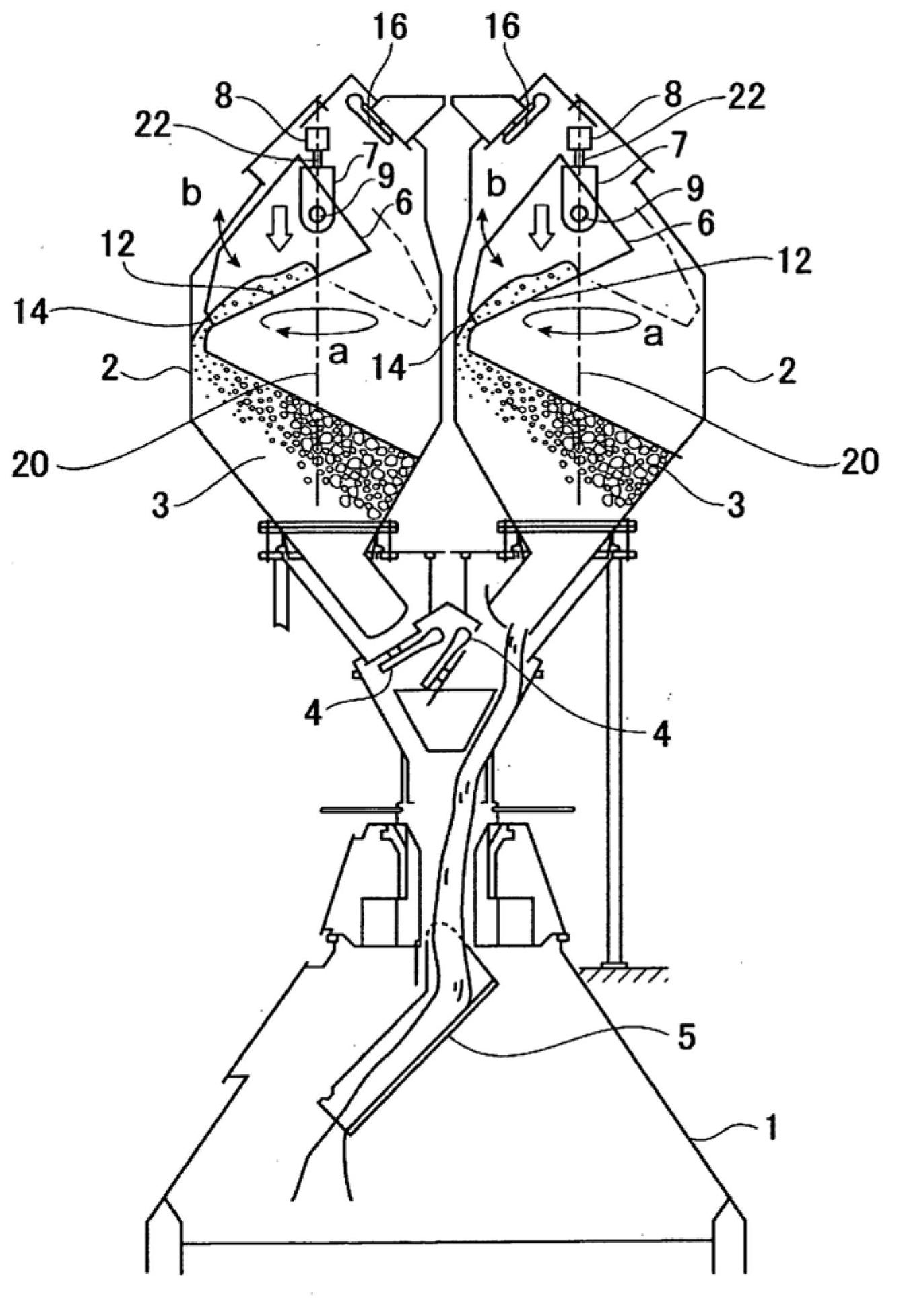

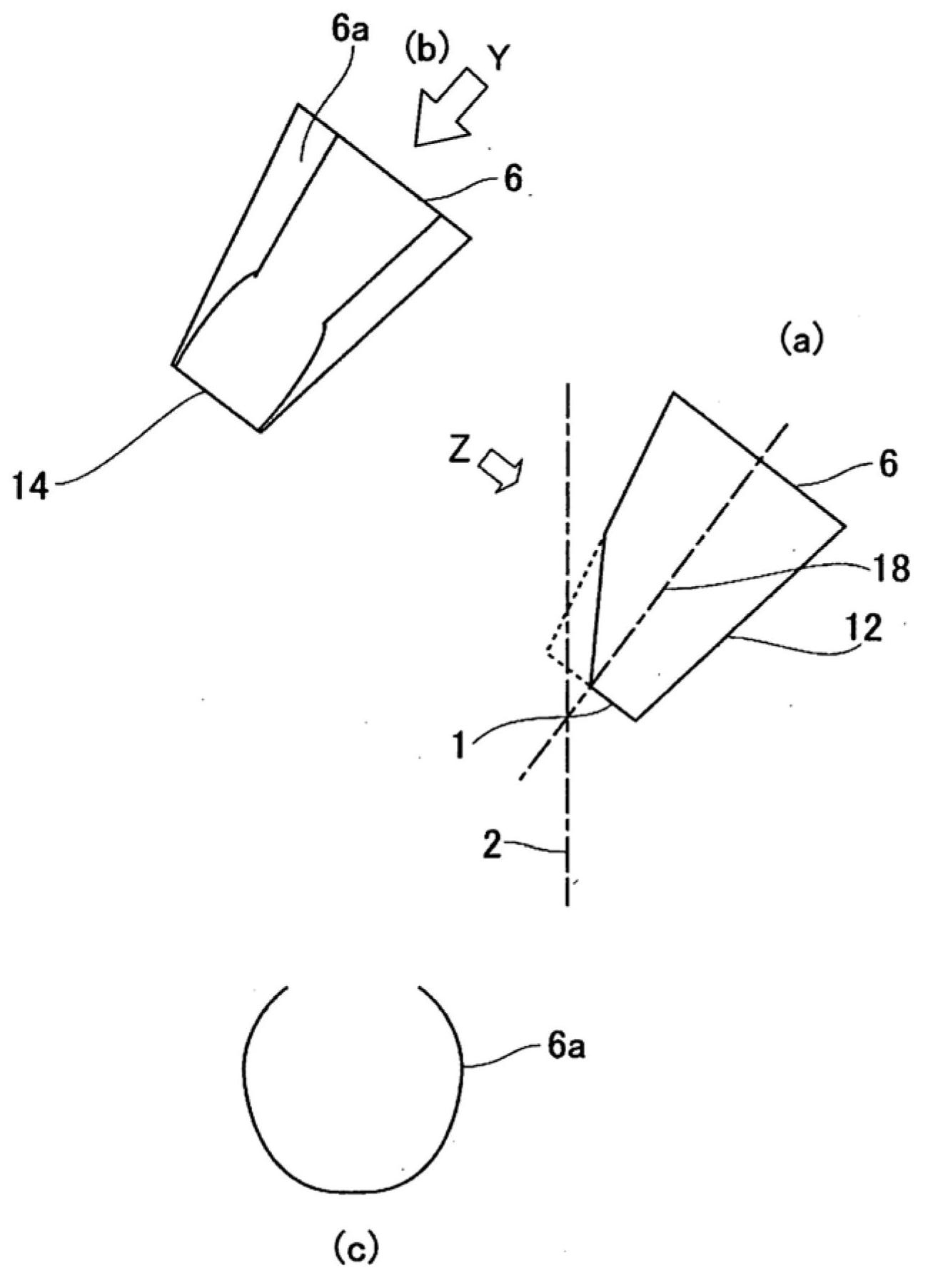

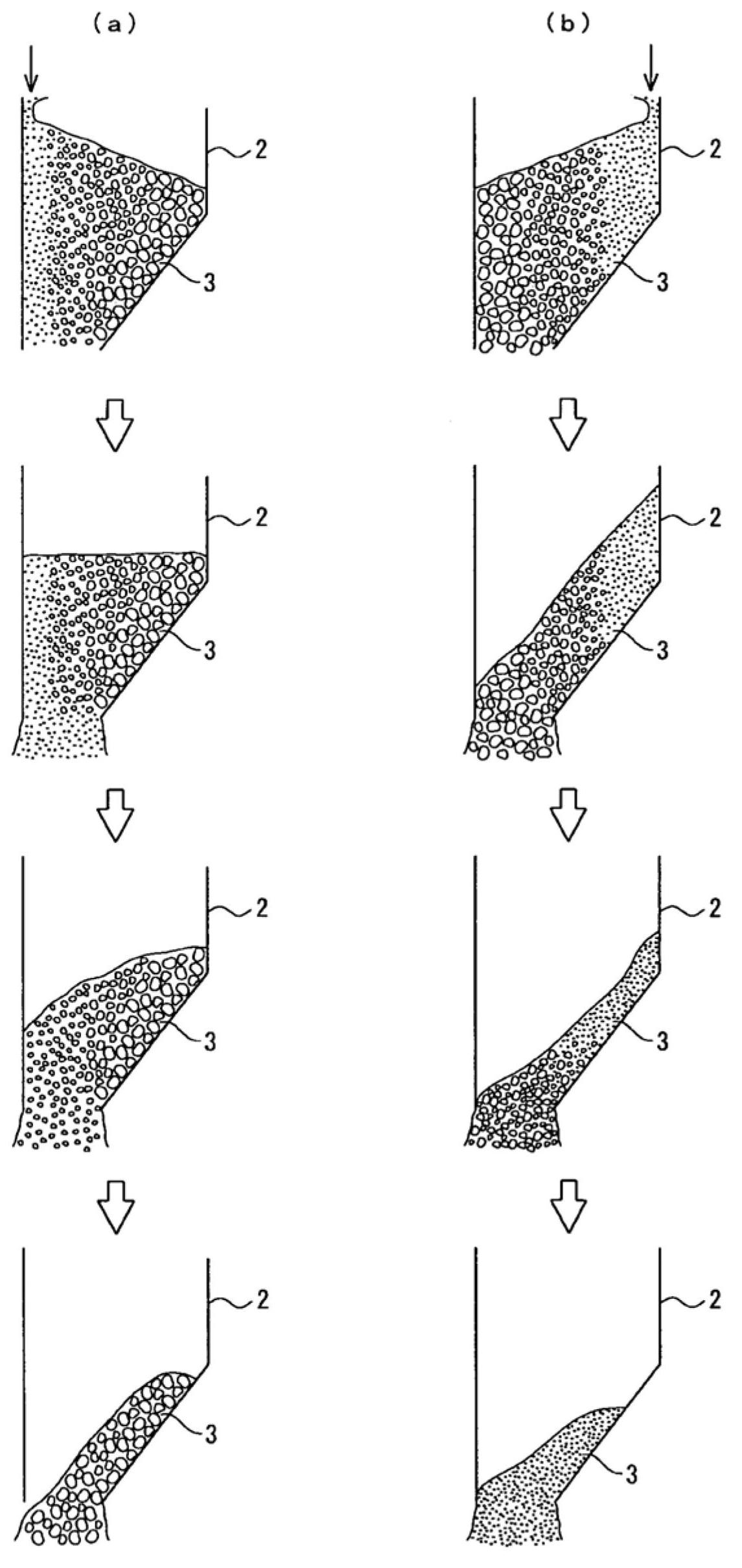

[0020] An embodiment of the raw material segregation device of the blast furnace roof raw material warehouse of the present invention will be described with reference to the accompanying drawings.

[0021] figure 1 It is a longitudinal sectional view of the blast furnace roof to which the automatic covering structure of this Example is applied. A plurality of raw material bins 2 are arranged above the furnace roof of the blast furnace 1 . The raw material silos 2 respectively store the raw materials 3 to be charged into the blast furnace 1 . Coke and iron ore can be cited as examples of the charged raw material 3 . A gate 16 is provided at the upper end of the raw material bin 2, and by opening the gate 16, the loaded raw material 3 is loaded into the raw material bin. A gate 4 is provided at the lower end of the raw material bin 2 , and by opening the gate 4 , the charged raw material 3 inside is dropped into the blast furnace 1 . A distribution chute 5 is provided below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com