Method and equipment for purifying polycrystalline silicon through solidification crucible rotary electron beam melting

An electron beam smelting, polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of inability to realize continuous feeding and continuous discharging, increase the time for multiple smelting, and be unfavorable for industrialized production. Reduced purification time, compact structure, increased continuity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

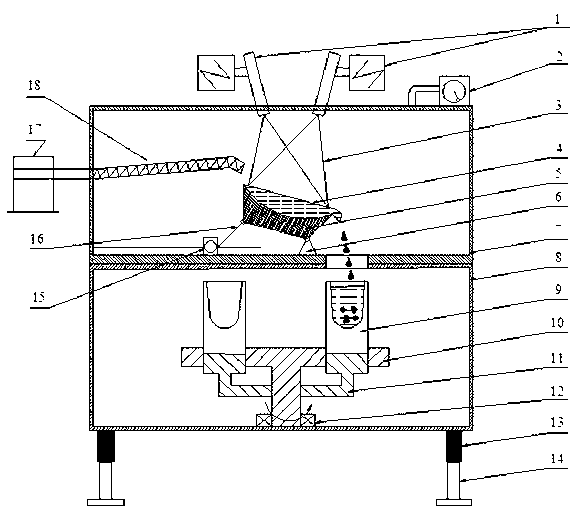

[0023] Such as figure 1 and figure 2 The equipment used in the method of solidifying crucible rotary electron beam melting and purifying polysilicon shown in the figure is composed of an upper chamber 7 and a lower chamber 8 as a whole, the upper chamber 7 is fixedly installed on the ground base support, and the upper chamber Two electron guns 1 are installed on the top of the chamber. The vacuum pump group 2 communicates with the upper chamber 7 through a vacuum pipeline. The vacuum pump group 2 includes a mechanical pump, a Roots pump and a diffusion pump. A vacuum gauge is installed on the vacuum pipeline.

[0024] On the bottom plate of the upper chamber 7, the melting crucible 5 is movably installed through the crucible frame 6, the sliding mechanism 15 is installed on one side of the melting crucible through the transmission rod 16, the charging box 17 is fixedly installed on the side wall of the upper chamber 7, and the feeding belt 18 is fixed Installed on the chargi...

Embodiment 2

[0027] Utilize the electron beam smelting equipment described in embodiment 1 to smelt and purify polycrystalline silicon, concrete steps are as follows:

[0028]The first step of material preparation and pre-treatment: First, use the feeding belt to transport the high-phosphorus silicon material in the charging box with a phosphorus content of 10ppmw to the melting crucible, until the silicon material fills 95% of the volume of the melting crucible, turn on the vacuum pump group, and the chamber The vacuum degree is pumped to 5×10 -2 Pa; preheat the electron gun, set the high voltage to 30kV, and after the high voltage is stable for 10 minutes, turn off the high voltage, set the beam current of the electron gun to 200mA, and perform preheating. After preheating for 10 minutes, turn off the beam current of the electron gun;

[0029] The second step of smelting and purification: turn on the high voltage and beam current of the electron gun at the same time, and after the voltag...

Embodiment 3

[0032] Utilize the electron beam smelting equipment described in embodiment 1 to smelt and purify polycrystalline silicon, concrete steps are as follows:

[0033] The first step of material preparation and pre-treatment: first, use the feeding belt to transport the high-phosphorus silicon material with a phosphorus content of 34ppmw in the charging box to the melting crucible until the silicon material fills 92% of the volume of the melting crucible, turn on the vacuum pump group, and turn on the chamber Medium vacuum pumped to 3×10 -2 Pa; preheat the electron gun, set the high voltage to 31kV, and after the high voltage is stable for 8 minutes, turn off the high voltage, set the beam current of the electron gun to 150mA, and perform preheating. After preheating for 12 minutes, turn off the beam current of the electron gun;

[0034] The second step of smelting and purification: turn on the high voltage and beam current of the electron gun at the same time, after the voltage an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com