Method and device for efficiently and continuously smelting and purifying polysilicon with electron beams

An electron beam, polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problem of inability to achieve continuous feeding and continuous discharging, increase material consumption, energy consumption costs, and inability to smelt powder silicon materials, etc. problem, to achieve the effect of low cost, high production efficiency and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for efficiently and continuously melting and purifying polysilicon by electron beams. First, a stable high-purity silicon molten pool is formed in a crucible by electron beams, and then the silicon powder to be purified is continuously dropped into the molten pool through a feeding vacuum chamber, and melted after rapid melting. , so as to remove the impurity phosphorus in the silicon powder, and the obtained low-phosphorus silicon liquid periodically overflows from the crucible, forms a silicon block in the water-cooled inclined copper tank, and falls into the collection cylinder for cooling, and finally flows out continuously through the discharge vacuum lock chamber. Material, complete the process of continuous purification of polysilicon powder.

Embodiment 2

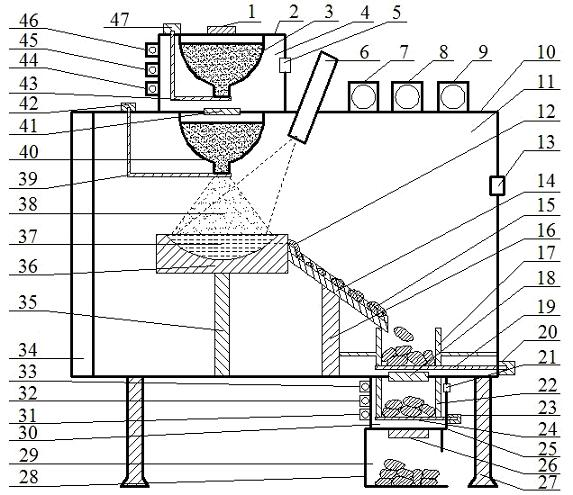

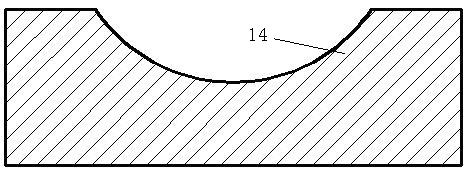

[0028] Such as figure 1 The equipment shown is a high-efficiency, continuous smelting and purification of polysilicon by electron beams. It consists of a vacuum cover 34, a vacuum furnace wall 10, a feeding vacuum lock chamber furnace wall 2, a discharging vacuum lock chamber furnace wall 25, and a collection chamber furnace wall 28 for powder loading. Cover 1 and blanking cover 26 form the shell of the device; the whole device is composed of four chambers, namely the feeding vacuum lock chamber 4, the vacuum chamber 11, the discharging vacuum lock chamber 30, and the collection chamber 29; the vacuum furnace wall 10 is installed on the support leg 27, the charging vacuum chamber furnace wall 2 is installed above the vacuum furnace wall 10, and is connected through the powder falling vacuum valve 41. 18 connected, the upper end of the collection chamber furnace wall 28 is connected to the vacuum lock chamber furnace wall 25, the lower end is fixed on the ground, and connected ...

Embodiment 3

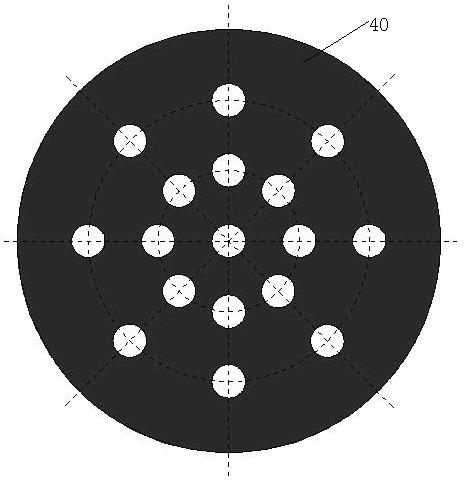

[0030] Adopt the equipment described in embodiment 2 to carry out efficient, continuous smelting and purification of polysilicon by electron beam, the specific process is: the low-phosphorus silicon block with a phosphorus content of 0.00004% is placed on the water-cooled copper crucible 36, and the loading amount of the low-phosphorus silicon block is At the three-fifth position of the water-cooled copper crucible 36, the lower powder baffle plate 39 is rotated to the position of blocking the bottom of the lower powder bucket 40 through the lower rotating mechanism 42, the powder falling vacuum valve 41 is opened, and the upper blocking plate 39 is turned by the upper rotating mechanism 47. The powder plate 43 is rotated to a position away from the bottom of the top loading powder bucket 3, the powder loading cover 1 is opened, and high phosphorus silicon powder 38 is added into the top loading powder bucket 3, and the high phosphorus silicon powder 38 will pass through the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com