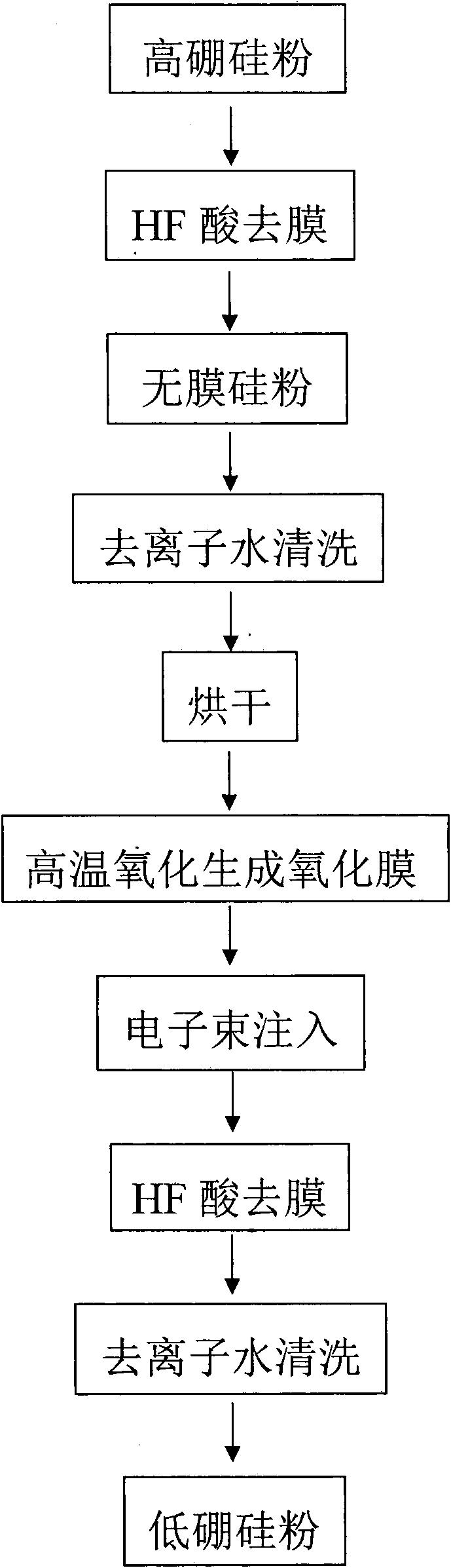

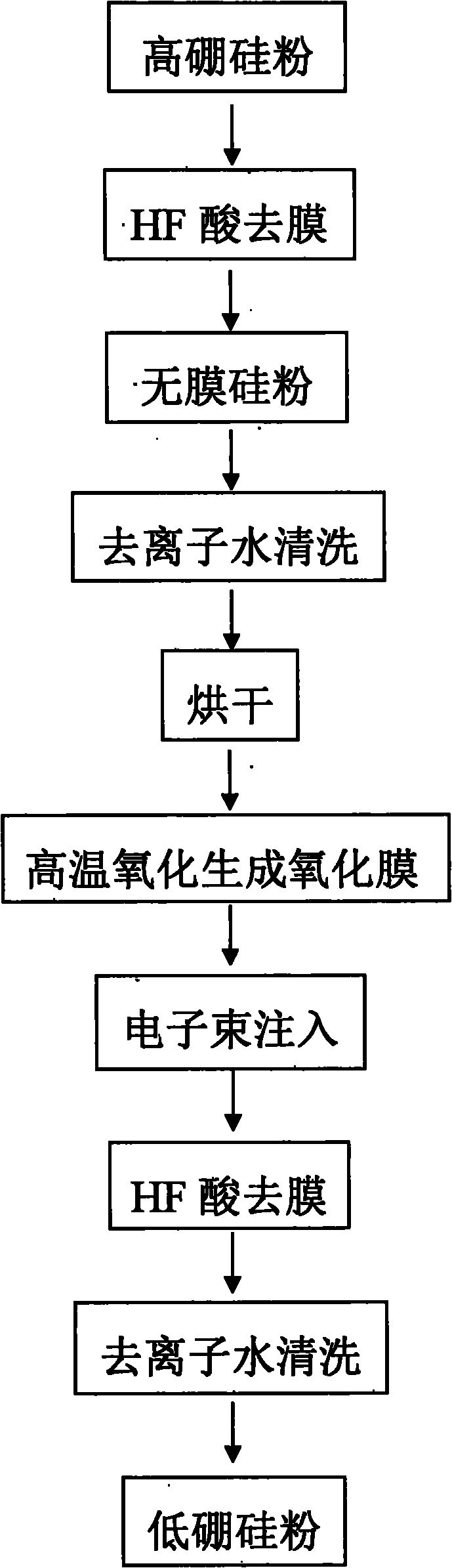

Method for removing boron impurities contained in polysilicon by injecting electron beams

A technology of electron injection and electron beam, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high application cost, low production efficiency, unfavorable industrial production, etc., and achieve high production efficiency, short cycle, and purification good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the manufacturing process of semiconductor devices, the silicon dioxide film has the function of absorbing boron, that is, in Si / SiO 2 The enrichment of boron exists on the side of the interface oxide layer. The diffusion rate of impurity boron in silicon is much faster than that in silicon dioxide, and in Si / SiO 2 The interface layer exists in a cationic state, and the SiO of the interface layer 2 One-way diffusion behavior occurred, macroscopically, there was a segregation effect, and the segregation coefficient (the content of boron in silicon / the content of boron in silicon dioxide) was 0.3. Studies have shown that the silicon dioxide layer with PLD (Peroxy linkage defects) has the effect of adsorbing boron. Because of its negative charge, according to the principle that the same-sex charges repel and the opposite-sex charges attract each other, boron atoms are segregated in the silicon dioxide layer during high-temperature heat treatment. In the process, elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com