Making and application methods for atlas of microstructure of titanium alloy

A technology of microstructure and manufacturing method, which is applied in the preparation of test samples, measuring devices, and material analysis through optical means, and can solve problems such as increased safety risks, thickening of intragranular sheets, and coarsening of grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Take the mechanical performance samples of the same furnace ZTA15 and the same furnace ZTC4 single-cast titanium alloy, and divide them into two batches and mark them before performing the mechanical performance test. One batch is directly processed according to HB5413 "Metal Room Temperature Tensile Test Method" A short sample with a diameter of 8mm was tested for mechanical properties, and the test data was recorded. Another batch of short samples with a diameter of 8mm was processed according to HB5413 "Metal Room Tensile Test Method" after hot isostatic pressing, and the mechanical properties were tested. Test, and record the test data, and then classify according to the limit range of mechanical properties and the range of elongation;

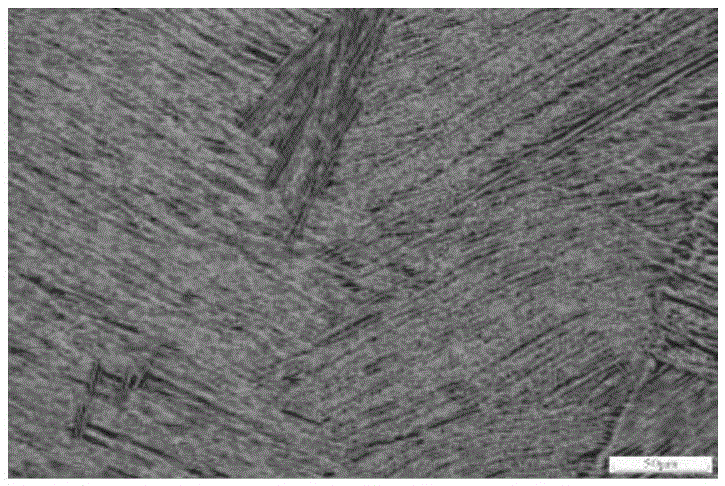

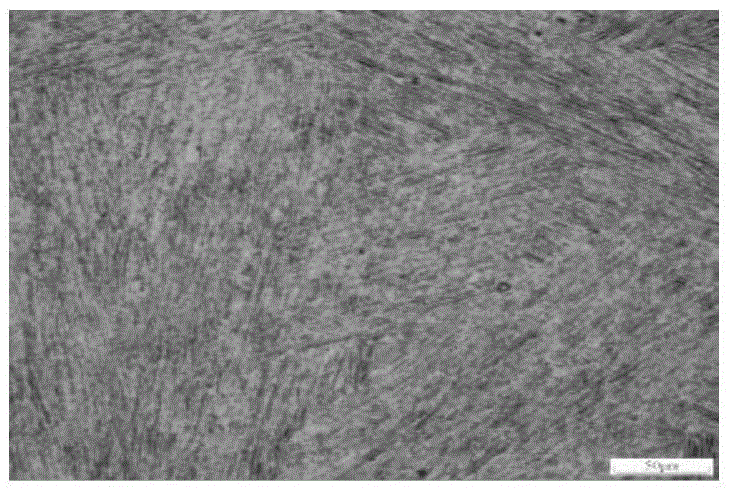

[0043] (2) Grind and polish the sample after the mechanical performance test to make a metallographic sample, and then observe it under an optical microscope at a magnification of 200 times, and select the most representative fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com