Constituent control method used in thermal simulation experiment of steel

A control method and thermal simulation technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of prolonging the research and development cycle and research and development costs of ultra-fine grained steel materials, duplication of labor and equipment, etc., and achieve convenient maintenance. The effect of upgrading, saving research and development time, and improving the level of research and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

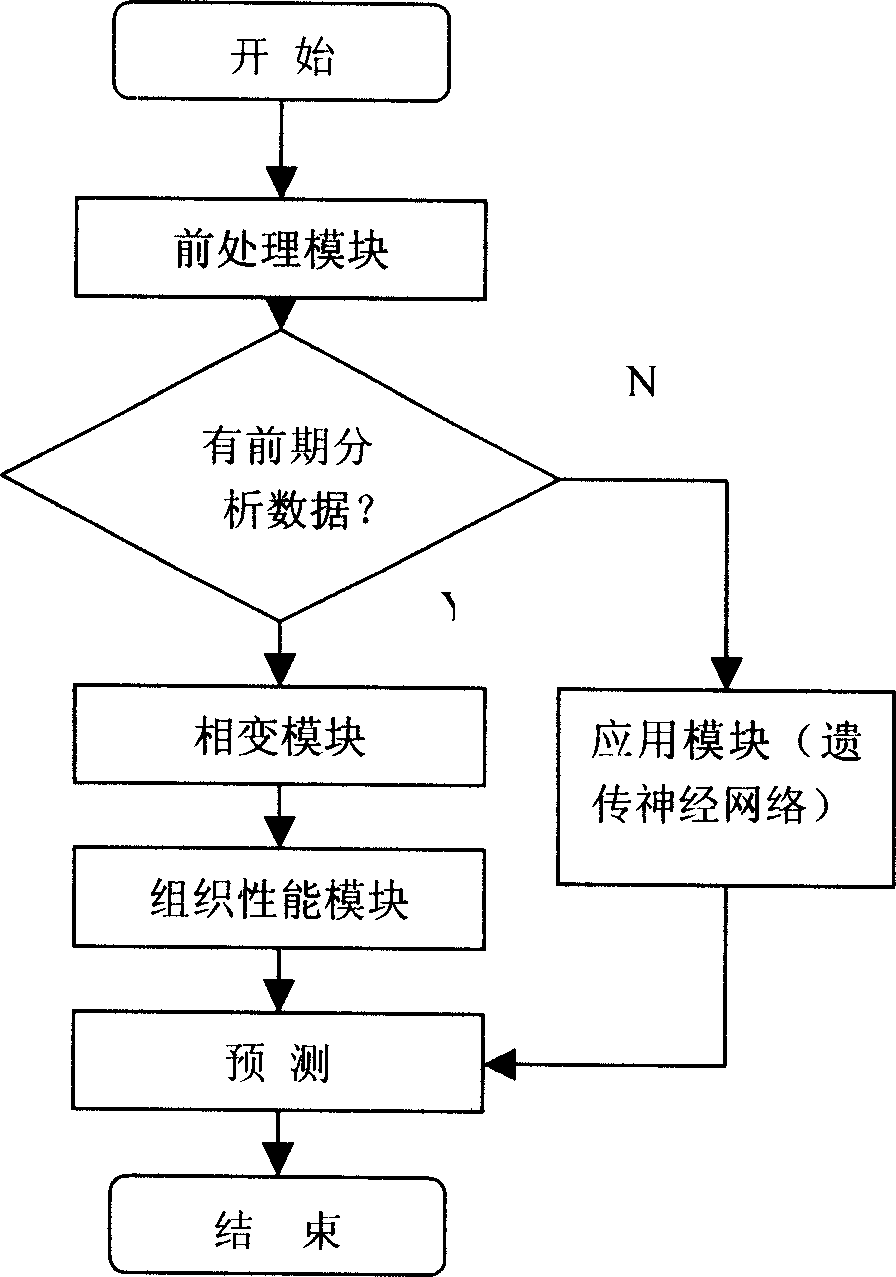

Image

Examples

Embodiment Construction

[0031] As far as the thermal simulation test of ultra-fine grain steel is concerned, its input space includes: chemical composition of test steel, deformation temperature, deformation amount, deformation pass, deformation rate, interval time, holding time, cooling conditions and other ten parameters; The output space is mainly the grain size and percentage content of ultrafine-grained ferrite and the corresponding mechanical properties. The samples for training the network are taken from the Gleeble-2000 thermal simulation test data of low-carbon microalloy steel. 0.8, P: 0.008-0.012, S: 0.005-0.008, V: 0.02-0.13, Nb: 0.02-0.13, N: 0.003-0.008. When the development time is limited and the process data is limited, the genetic neural network model of the application module is used to analyze various factors. After entering the main interface of the system's genetic neural network, select the submenu of "Build Genetic Neural Network" under "Application Module", and the "Build Ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com