Double metal composite plate strip solid-liquid vibration cast rolling device and method

A composite strip and bimetal technology, applied in metal processing equipment, metal rolling, metal rolling, etc., can solve problems such as poor bonding strength of composite material interface, limited composite strength of composite process, and problems that cannot be fundamentally solved, and achieve Uniform distribution of alloy composition, improvement of structural composition segregation and rolling force fluctuation, and reduction of horizontal offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

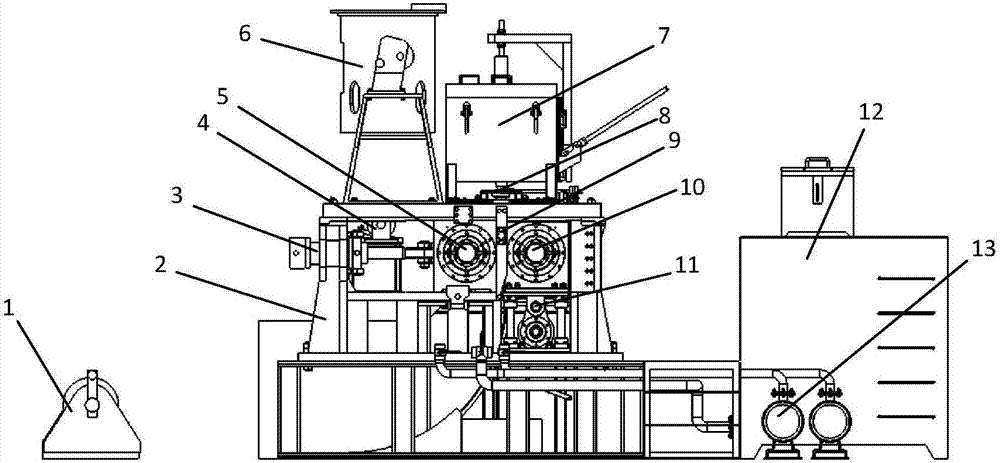

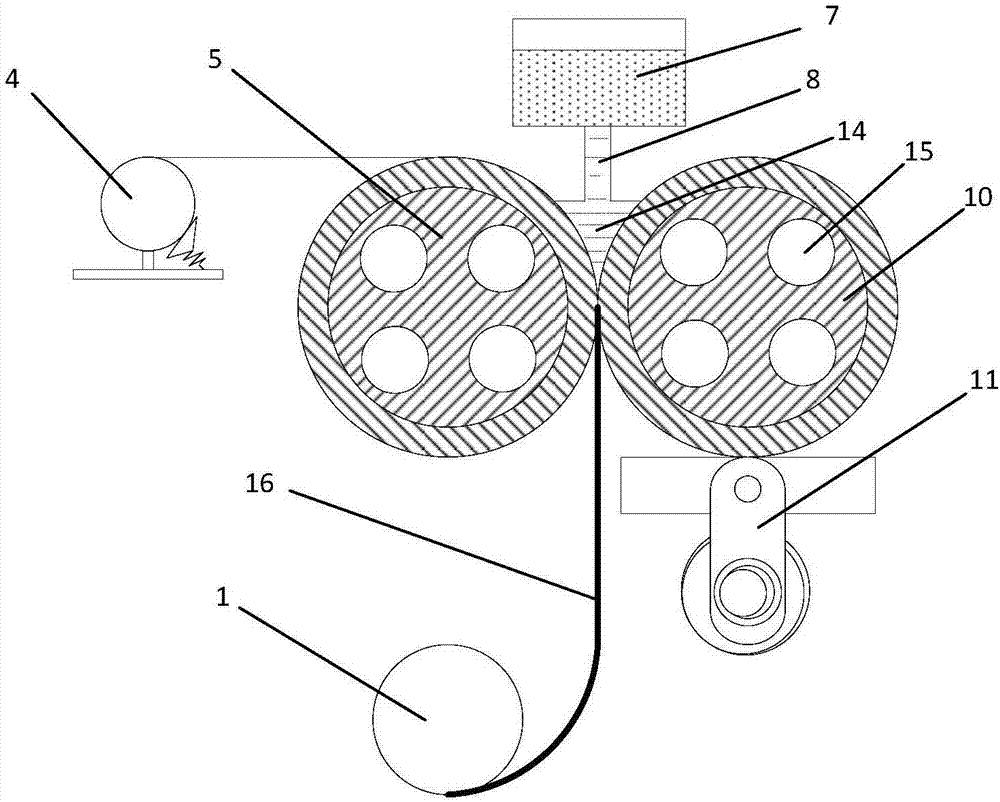

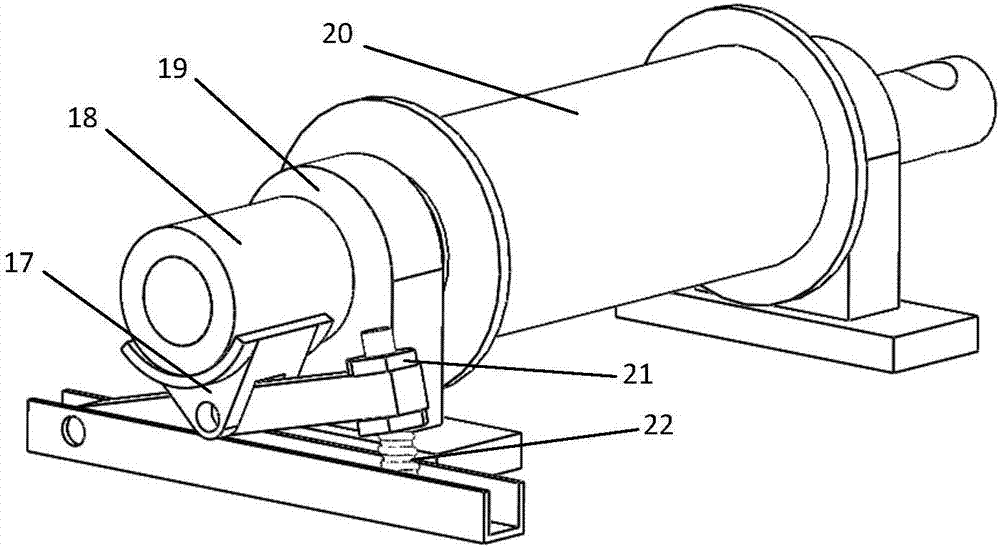

[0031] Taking the copper-aluminum composite board as an example, the equipment and method of the present invention are used to process the copper-aluminum composite board strip. Metal A is made of industrial red copper, and metal B is made of industrial pure aluminum. The thickness of the composite board is 2mm, and the copper-aluminum thickness ratio is about 1:3, the product width is 350mm. According to the thickness specification of the finished product, the roll gap between the two casting rolls is set to be 2mm, considering the compression of the solid metal A strip blank by composite rolling, a copper strip with a thickness of 0.6mm is used as the solid base material. A 0.6mm thick copper strip is wound on the tension roller 20 of the self-tensioning uncoiling mechanism 4, and the end of the drawn blank is led to the coiler 1 through the gap between the two casting rolls and fixed on the coiler 1. Under the action of the tightening force, ensure that the metal A strip bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com