Method for online test of steel plate mechanic property during rolling process

A rolling process and mechanics technology, applied in the field of steel rolling, can solve the problems of restricting the development of TMCP technology, uneven structure and performance, etc., and achieve the effect of convenient program maintenance and secondary development, fast response speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

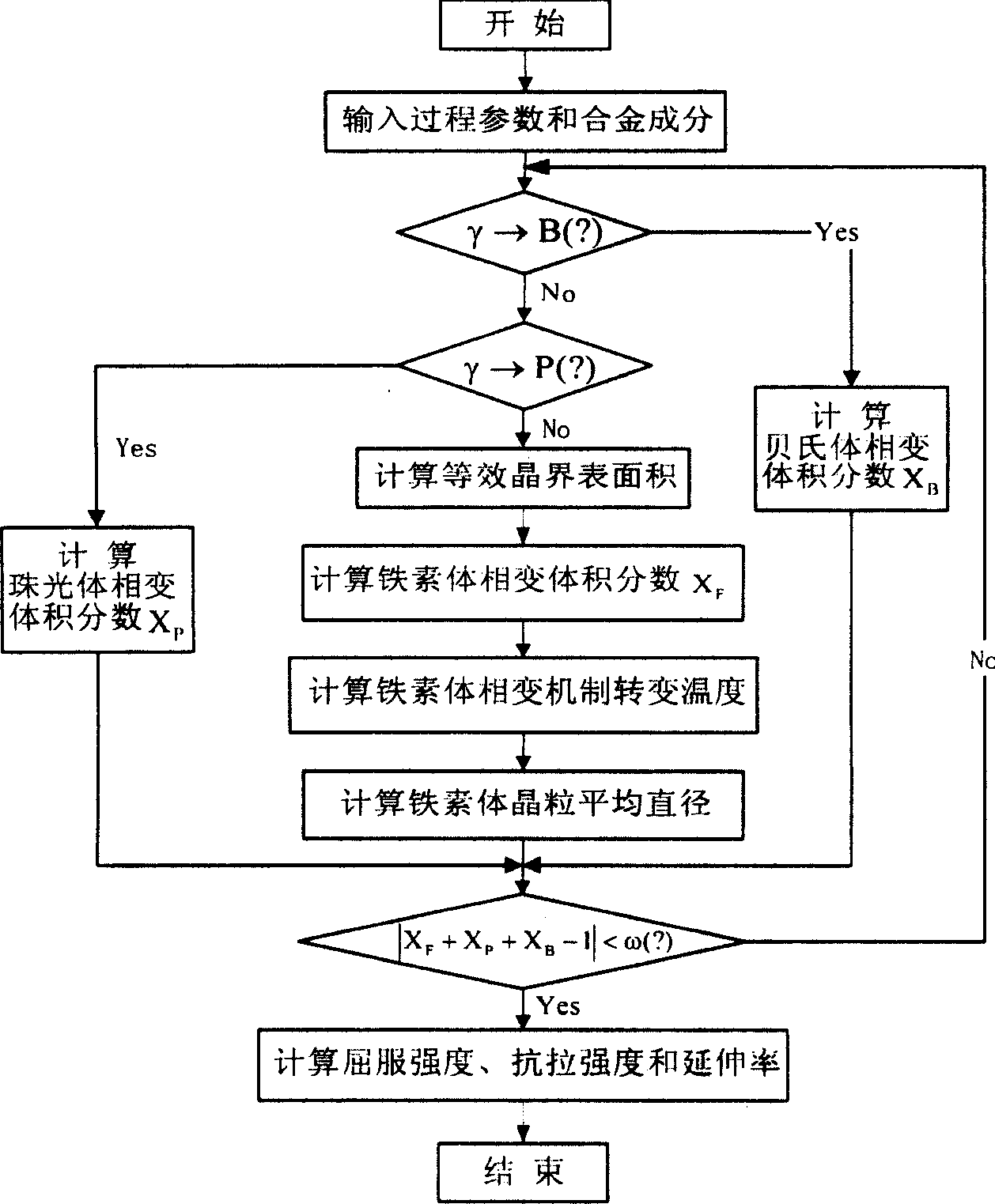

[0113] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0114] parameters

parameter value

parameters

parameter value

parameters

parameter value

parameters

parameter value

A

K 1

K 2

K 3

K 4

K 5

K 6

the s

1.14×10 5

2.07×10 11

6.33×10 -15

1.2

2.01×10 13

1.49×10 -14

6.82×10 -4

17.2

t

mu

b

p

q

r

u

v

4.55

7.5×10 10

2.5×10 -10

1.6

3.75

273

2.968

2.3×10 -3

w

z

m

ω

Y 1

Y 2

Y 3

T 1

0.52

1.9×10 -2

0.45

1.0×10 -6

22.06

12

3.97

14

T 2

T 3

E. 1

E. 2

E. 3

σ const

12

3.76

6.6

-1.3

0.026

47

[0115] Table 1

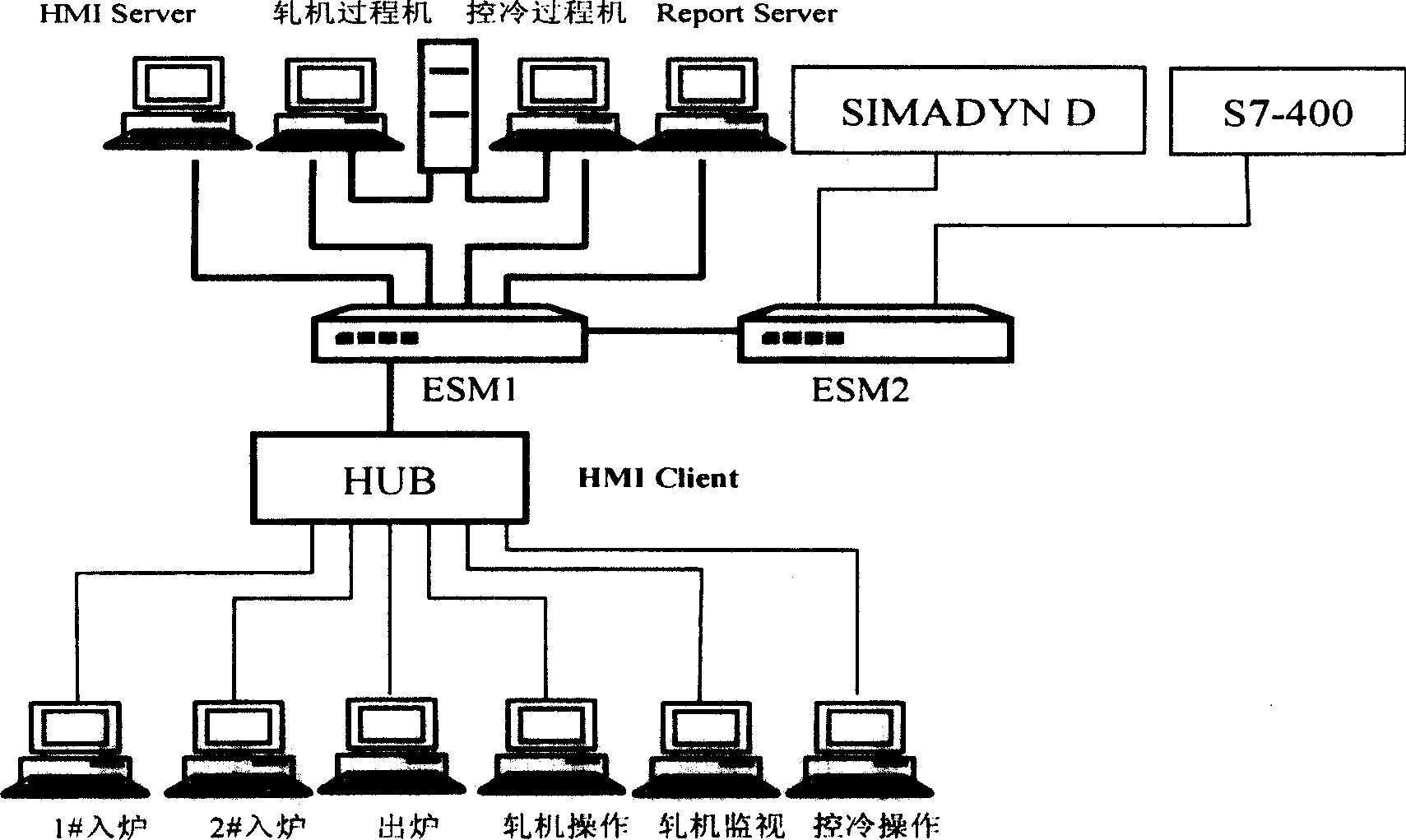

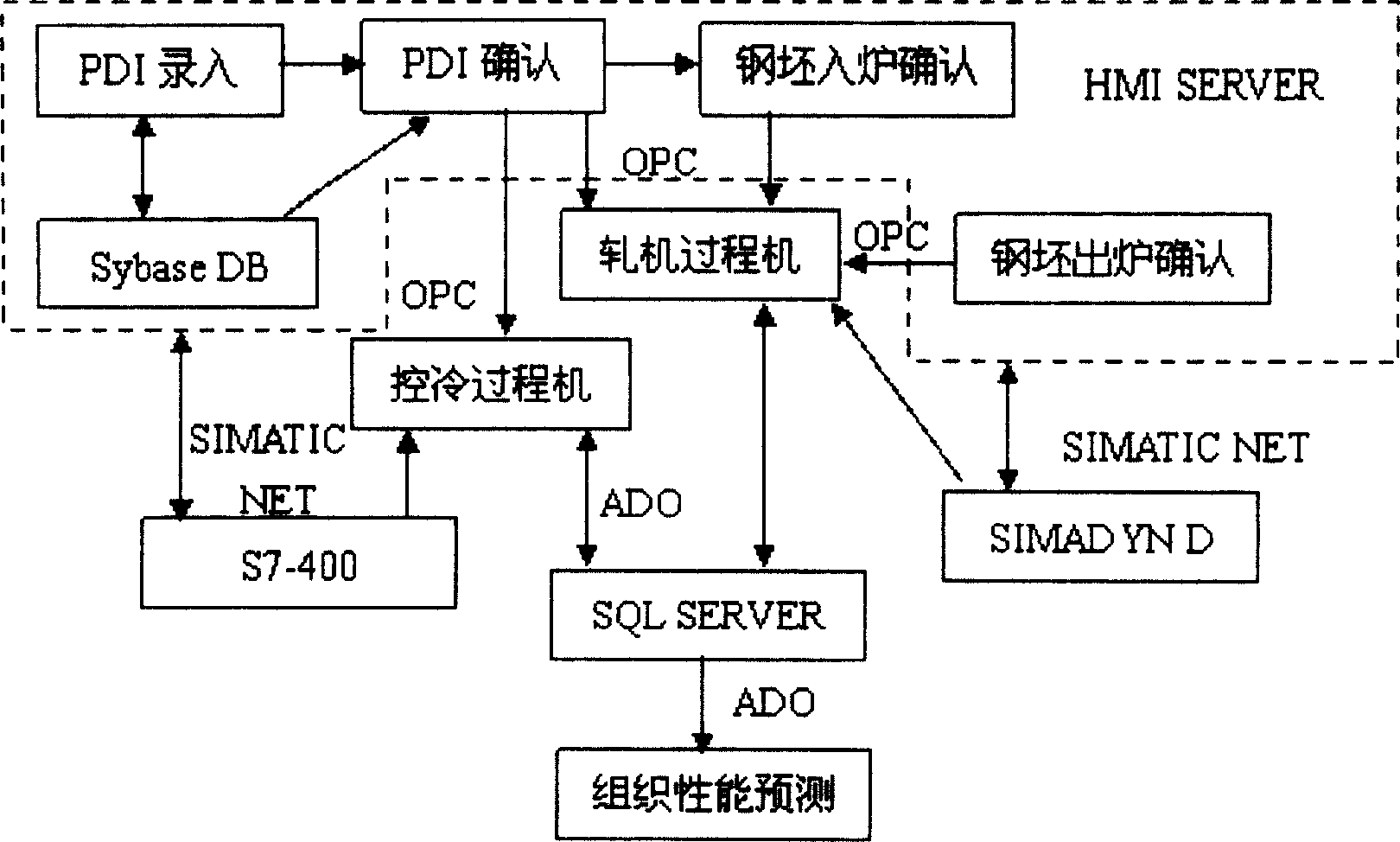

[0116] (2) Establish real-time com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com