Method and device for smelting and purifying polysilicon by using electron beams and adopting slag filtering

A technology of polysilicon and electron beams, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of unfavorable popularization of solar cells, inability to effectively remove polysilicon at the same time, and inability to effectively remove polysilicon, etc., to increase the contact area Large size, high production efficiency, and the effect of increasing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for smelting and purifying polysilicon by electron beam and slag filtration. Firstly, a slag-forming agent is heated and melted by a graphite heating element in a smelting crucible to form a slag-forming agent melt, which is maintained in a liquid state. Slowly add high phosphorus, high boron and high metal polysilicon fragments, high phosphorus, high boron and high metal polysilicon fragments are melted into silicon melt under electron beam bombardment, and smelted to remove impurity phosphorus, after this low The phosphorus silicon melt enters the diversion device through the diversion port of the water-cooled copper crucible. The impurity boron in the silicon melt reacts with the slagging agent to remove the impurity boron. Finally, when the melt in the melting crucible is full, stop adding polysilicon material, and heat the melt in the melting crucible to keep it in a liquid state for 3 minutes, and finally pass The ingot pulling mechanism pulls the ingot d...

Embodiment 2

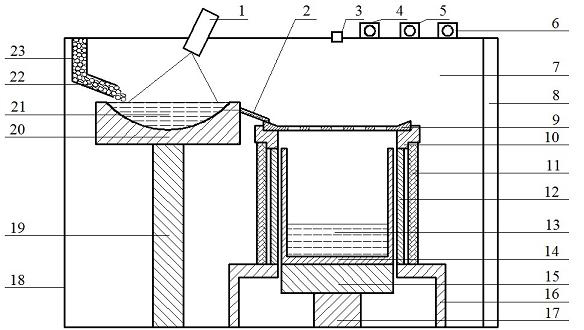

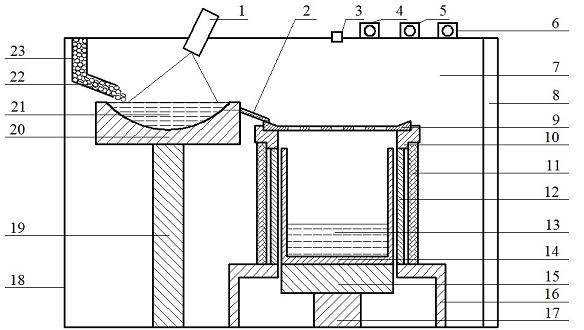

[0027] A kind of equipment for smelting and purifying polysilicon by electron beam and slag filtration. The equipment consists of a furnace door 8 and a vacuum furnace wall 2 to form a vacuum equipment. The inner cavity of the vacuum equipment is a vacuum chamber 7; A water-cooled ingot rod 17 is installed on the vacuum furnace wall 2 in the support base 16, the graphite block 15 is installed on the water-cooled ingot rod 17, the melting crucible 14 is placed on the graphite block 15, and the support base 16 is installed from the outside to the inside. The thermal insulation carbon felt 11 and the graphite heating element 12, the flow guide device is installed on the thermal insulation carbon felt 11 and the graphite heating element 12; the water-cooled support rod 19 is installed on the left side of the bottom of the vacuum chamber 7, and the water-cooled copper crucible 20 is installed on the water-cooled support rod 19 Above, the feeding device 23 is fixedly installed on the...

Embodiment 3

[0029] Adopt the equipment described in embodiment 2 to carry out the method for electron beam and slag filtration smelting purification polysilicon, its concrete steps are as follows:

[0030] The first step of material preparation: the mass percentage is SiO 2 70%, CaO20% and Na 2 CO 3 1200g of 10% slagging agent is spread on the bottom of the smelting crucible 14. At this time, the amount of slagging agent added is preferably 1 / 6 of the volume of the smelting crucible 14, and the furnace door 8 is closed;

[0031] The second step of pretreatment: use the mechanical pump 6 and the Roots pump 5 to pump the vacuum chamber 7 to a low vacuum of 7Pa, and then use the diffusion pump 4 to pump the vacuum chamber 7 to a high vacuum of 0.0015Pa; Put cooling water into the crucible 20 and the water-cooled ingot rod 17 to keep the temperature at 40°C; preheat the electron gun 1, set the high voltage to 30kV, and after the high voltage is stable for 5 minutes, turn off the high voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com