Method and equipment for purifying polycrystalline silicon by melting in electron beam shallow pool

A technology of shallow melting pool and electron beam, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc. It can solve the problems of unfavorable popularization of solar cells, difficult processing of silicon round rods, and large investment in equipment to achieve removal effect Good effect of improving energy utilization rate and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for smelting and purifying polysilicon in an electron beam shallow melting pool. First, a large high-phosphorus and high-metal polysilicon ingot to be purified is placed on a water-cooled lifting tray, and then the top of the silicon ingot is melted by an electron beam, and the molten silicon melt A shallow molten pool is formed in the space formed by the top of the silicon ingot, the water-cooled copper sleeve and the graphite sleeve. After melting for a certain period of time, the impurity phosphorus is removed, and then the water-cooled lifting tray is raised, and the low-phosphorus silicon melt passes through the guide after the liquid level rises. The orifice flows into the quartz crucible, and the ingot is pulled down under the action of heat preservation for directional solidification and growth. Metal impurities are enriched to the top of the silicon ingot. After solidification, the top of the silicon ingot is cut off to remove metal impurities, and final...

Embodiment 2

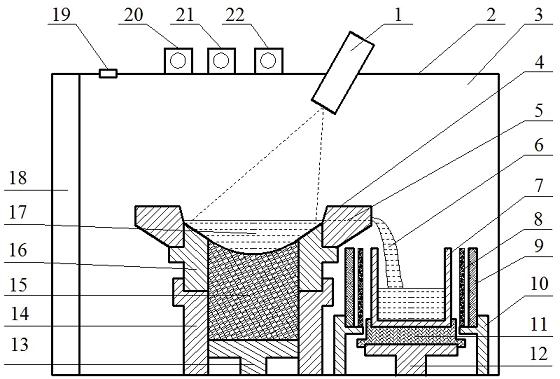

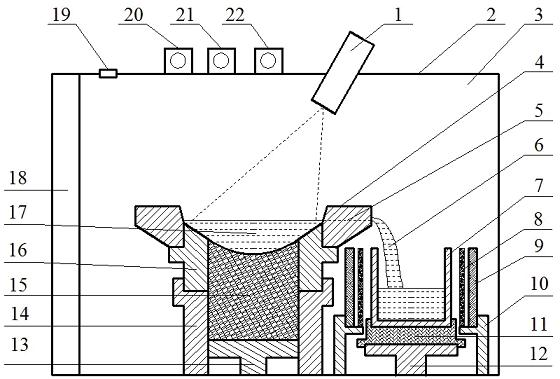

[0026] A kind of equipment for smelting and purifying polysilicon in an electron beam shallow melting pool. The equipment consists of a vacuum cover 18 and a vacuum furnace wall 2 to form a vacuum equipment. The inner cavity of the vacuum equipment is a vacuum chamber 3; A collar is installed on the 13, and the collar is made of a water-cooled copper sleeve 16 and a graphite collar, the water-cooled copper sleeve 16 is installed on the smelting support base 14, the graphite collar 4 is placed on the water-cooled copper sleeve 16, and the smelting support base is equipped with The water-cooled lifting tray 13 has a diversion port 5 on one side of the graphite collar, and an ingot pulling mechanism is installed under the diversion port. The ingot pulling mechanism adopts the ingot support base 10 and the water-cooled ingot rod 12 to be installed at the bottom of the vacuum furnace wall 2 , the thermal insulation sheath 9 and the graphite heating element 8 are installed on the ing...

Embodiment 3

[0028] Adopt the equipment described in embodiment 2 to carry out the method for smelting and purifying polysilicon by electron beam shallow melting pool, its specific steps are as follows:

[0029]The first step of material preparation: lower the water-cooled lifting tray 13 to the bottom of the smelting support base 14, and then place large high-phosphorus and high-metal silicon ingots 15 with a phosphorus content of 0.0025% and a total metal impurity content of 0.015% on the water-cooled lifting tray 13 On top, the top of the high-phosphorus, high-metal silicon ingot 15 should be level with the upper surface of the graphite collar 4, and the vacuum cover 18 should be closed;

[0030] In the second step pretreatment, the vacuum is extracted, and the vacuum chamber 3 is pumped to a low vacuum of 7Pa with a mechanical pump 20 and a Roots pump 21, and then the vacuum chamber 3 is pumped to a high vacuum of 0.0018Pa with a diffusion pump 22; Cooling water is passed into the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com