Method for preventing 65 Mn hot rolled steel coil from collapsing by phase-change thermal expansion

A technology of hot-rolled coil and phase transformation heat, applied in metal rolling, temperature control, etc., can solve problems such as discontinuous change in thermal expansion, and achieve the effects of low cost, optimized physical quality, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

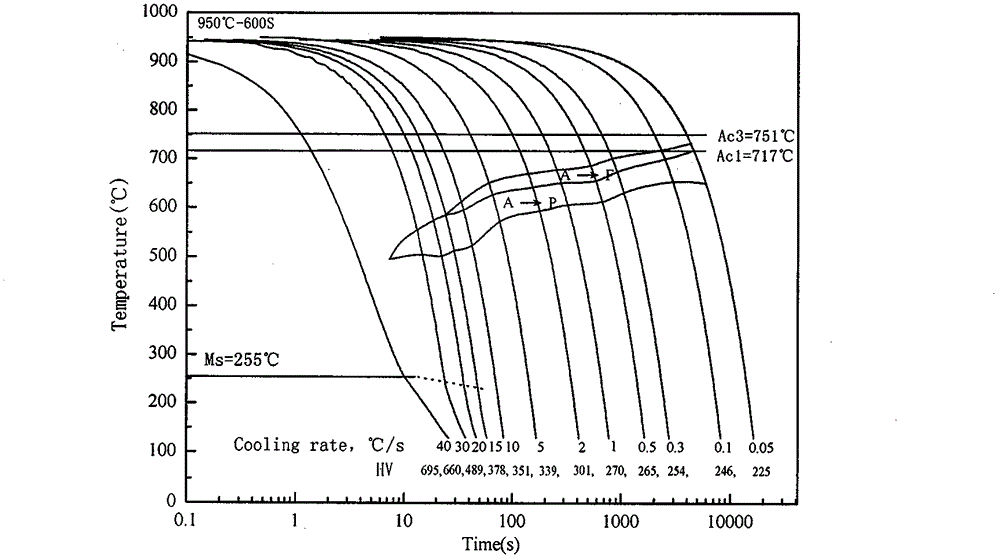

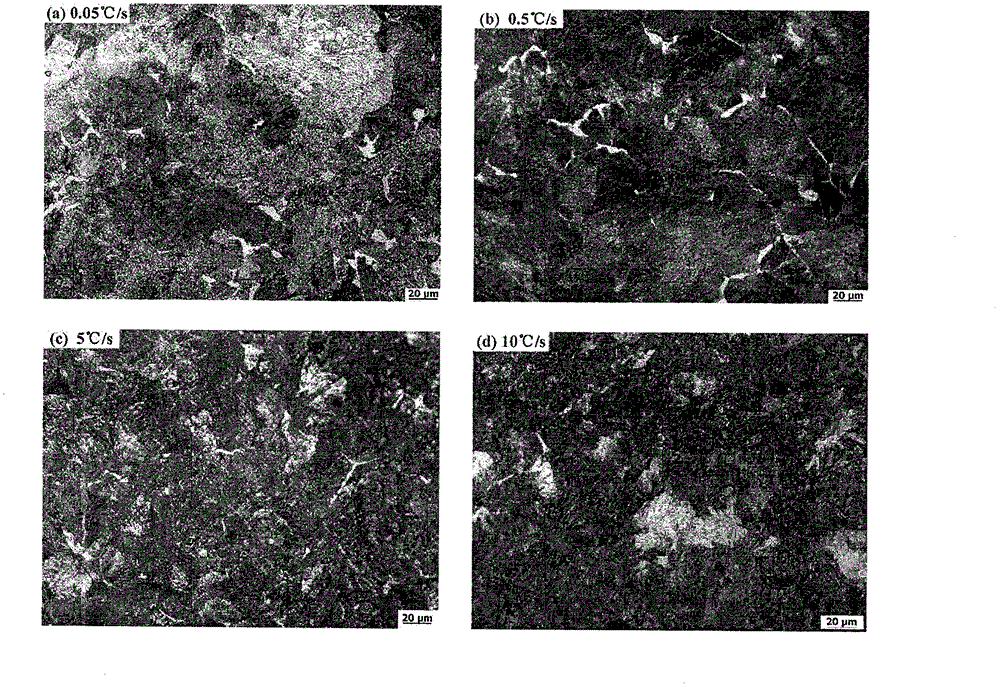

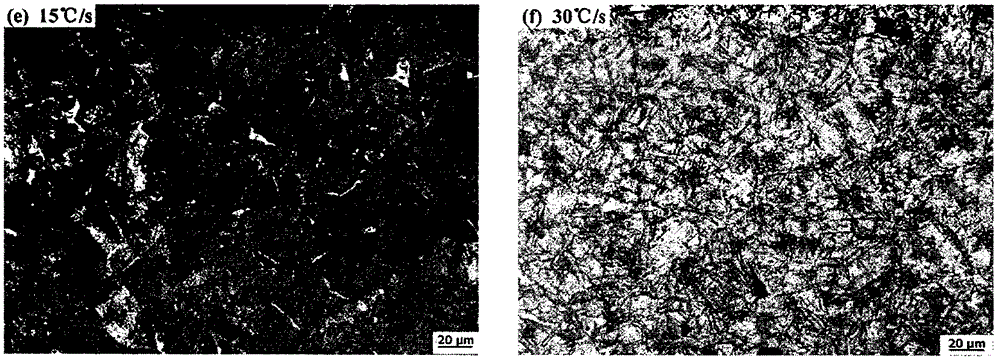

[0015] In the test, the CCT curve of 65Mn steel was determined by dilatation method combined with metallographic-hardness method. First, the critical point Ar of 65Mn steel was measured on the Gleeble-3500 thermal simulator 1 、Ar 3 、Ac 1 、Ac 3 and M s , and then measure the expansion curve of 65Mn steel during continuous cooling at 12 different cooling rates. According to the inflection point or tangent point on different expansion curves, combined with the metallographic structure, the phase transition temperature can be determined, and finally the continuous cooling transition curve of 65Mn steel can be obtained . The chemical composition is shown in Table 1.

[0016] Table 1 Chemical composition of 65Mn test billets (mass fraction, %)

[0017]

[0018] The cast slab smelted in the laboratory was forged to an intermediate slab with a thickness of 35 mm, and homogenized annealed. Then use a wire cutting machine to add a sample of Φ8mm×15mm on the intermediate blank....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com