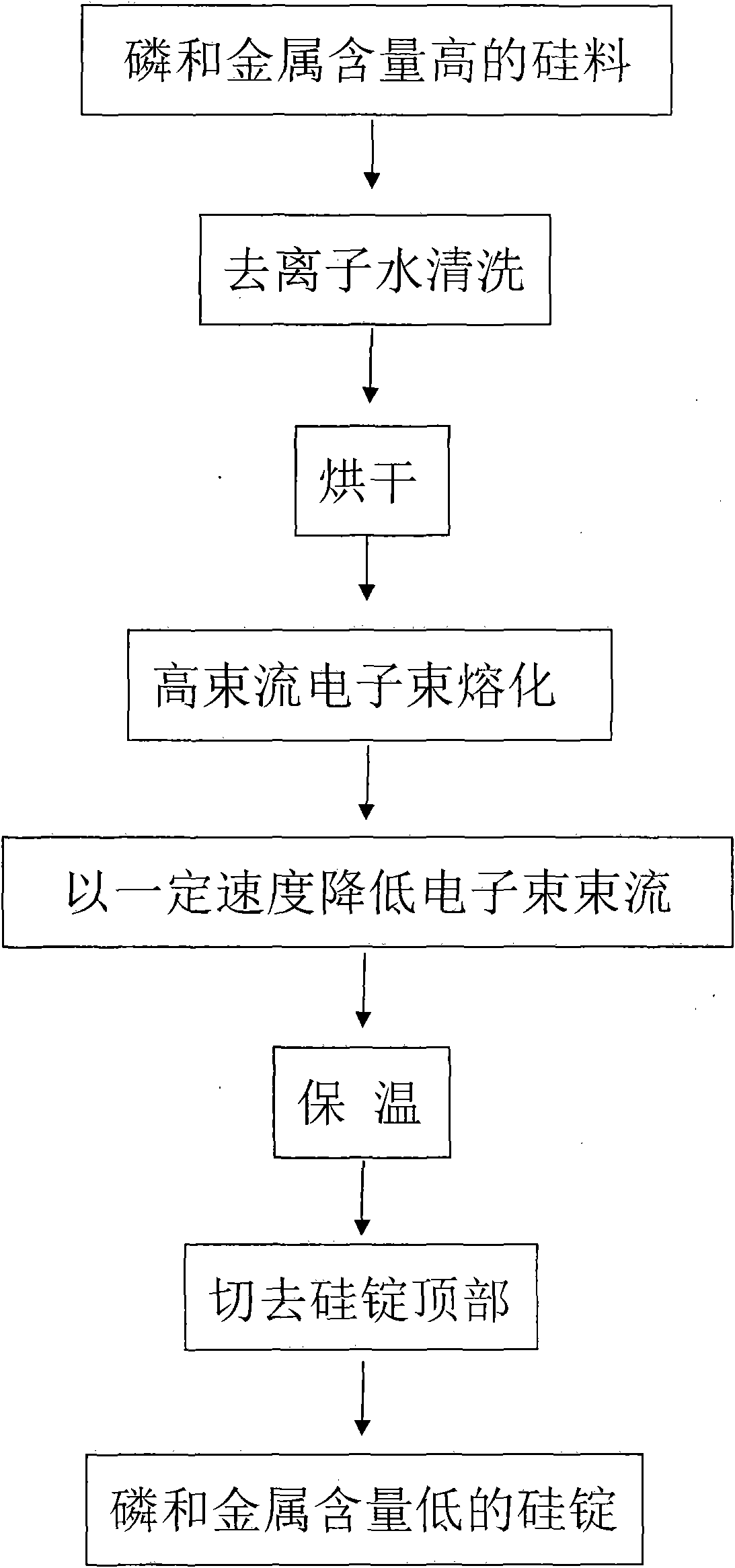

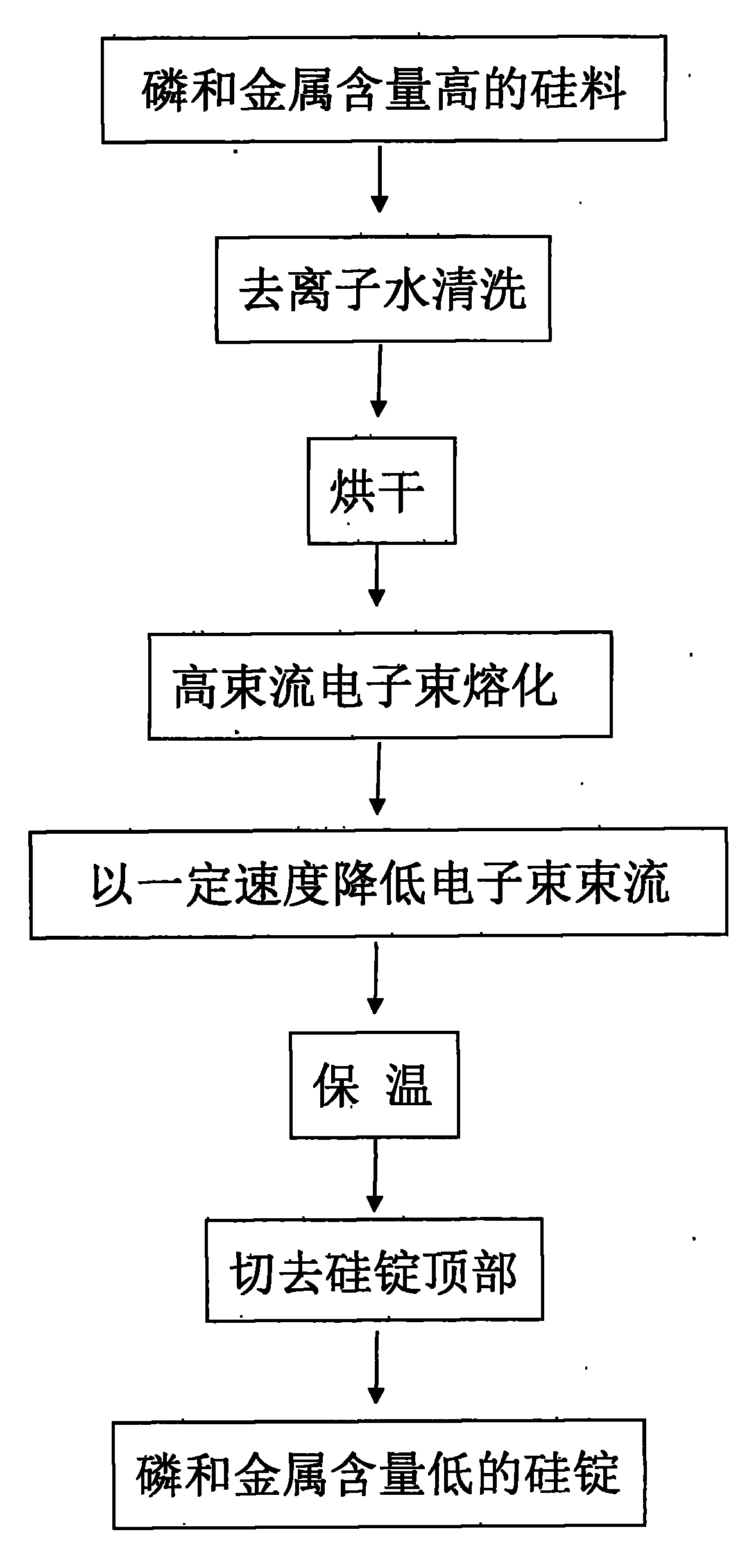

Method for purifying polycrystalline silicon by electron beam gradient smelting

An electron beam and polysilicon technology, applied in chemical instruments and methods, silicon compounds, sustainable manufacturing/processing, etc., can solve the problem of affecting the photoelectric conversion efficiency of solar cells, affecting the resistivity carrier life of silicon materials, and the inability to remove metal impurities and other problems to achieve the effect of reducing process links, low cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Electron beam smelting technology is one of the important methods in the metallurgical preparation of solar-grade silicon, which is a process method that uses high-energy-density electron beams as a melting heat source. Electron beam can provide high-density energy in the process of smelting silicon material. After the energy is converted into heat, the temperature of silicon material will rise, thereby melting the silicon material. The molten silicon in contact with the copper crucible starts to solidify first, and as the beam current continues to decrease, the solidification proceeds from the bottom to the top, thereby realizing the effect of solidifying at the bottom first and gradually solidifying upwards, resulting in a segregation effect, and metal impurities with a large segregation coefficient go to the The liquid area is enriched, and gathers at the top of the silicon ingot at the last solidified position. Metal impurities can be removed after cutting off the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com