Method for predicting hot-rolling Nb-containing band steel organization and mechanical properties

A microstructure and performance technology, applied in the field of steel rolling, can solve the problems of difficulty, unoptimistic effect, no microstructure evolution and mechanical properties of Nb-containing strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0156] A method for predicting the microstructure and mechanical properties of hot-rolled strip steel. Taking the production of 1700mm hot-rolled WL510 strip steel in a certain steel factory as an example, the present invention is further described in detail in conjunction with the accompanying drawings and examples.

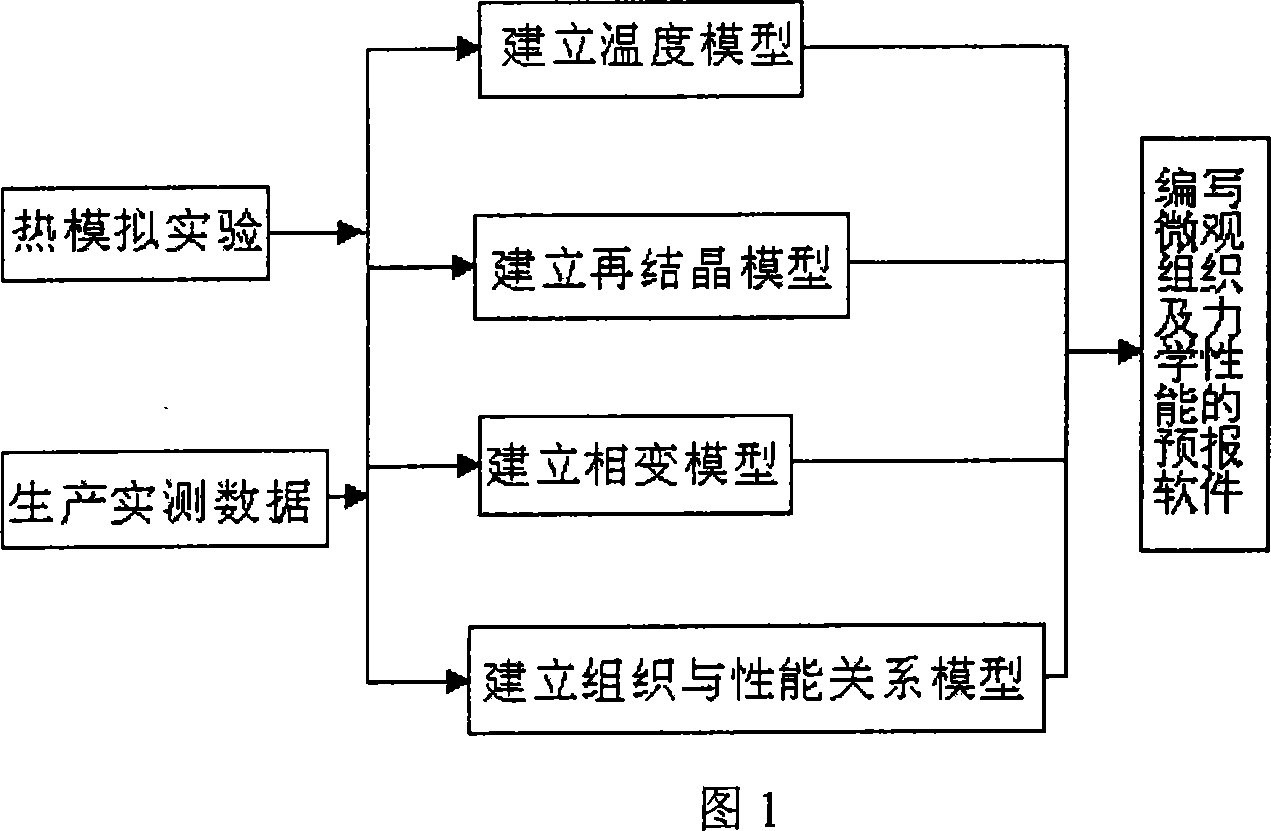

[0157] This embodiment is shown in Figure 1, based on the physical metallurgical model, using the method of combining thermal simulation experiments and industrial production measured data analysis, to establish a mathematical model for the structure and mechanical properties of hot-rolled Nb-containing strip steel; and using VB language Compilation of software for forecasting microstructure and mechanical properties of hot-rolled Nb-containing strip steel.

[0158] This embodiment includes the following steps:

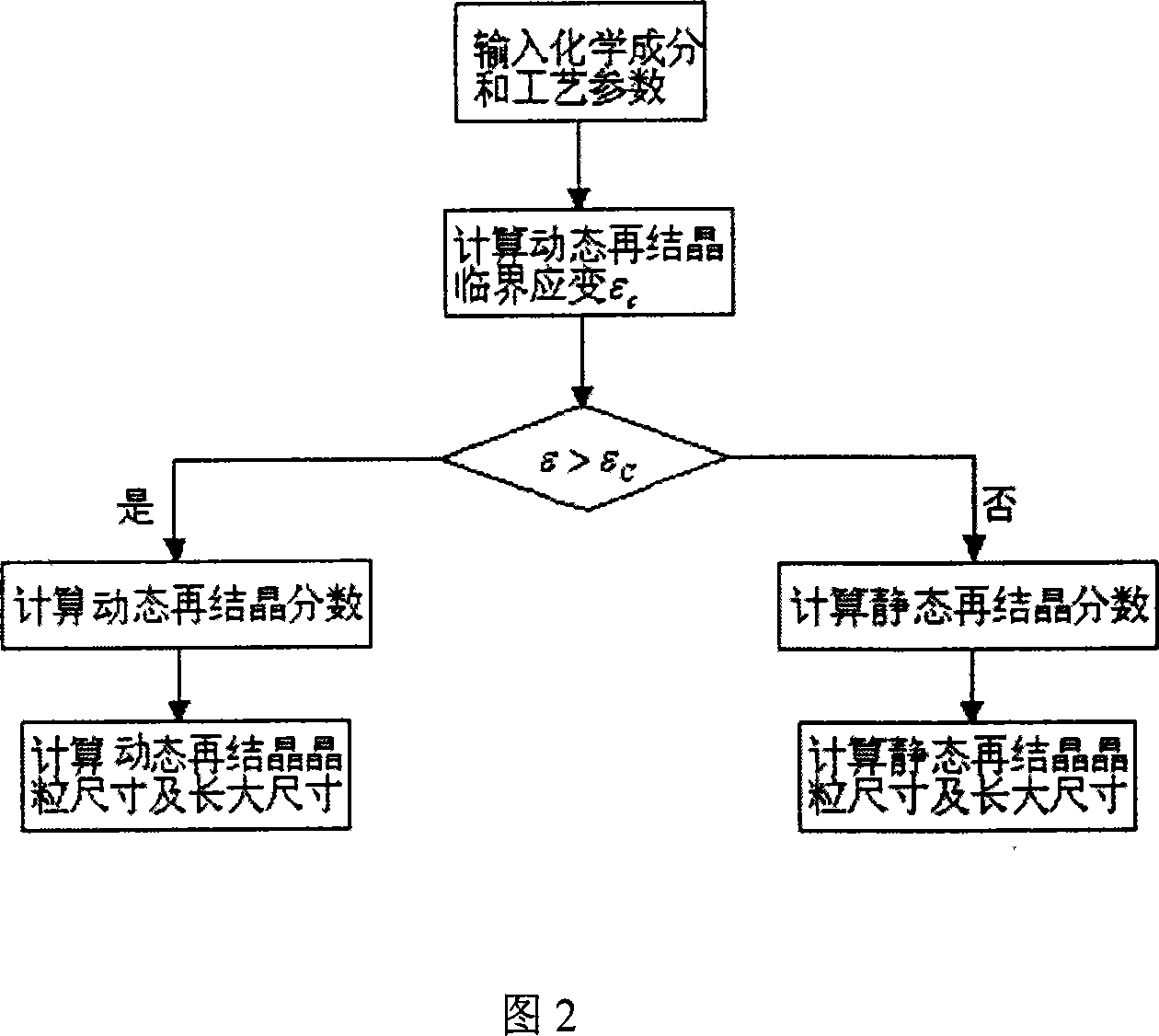

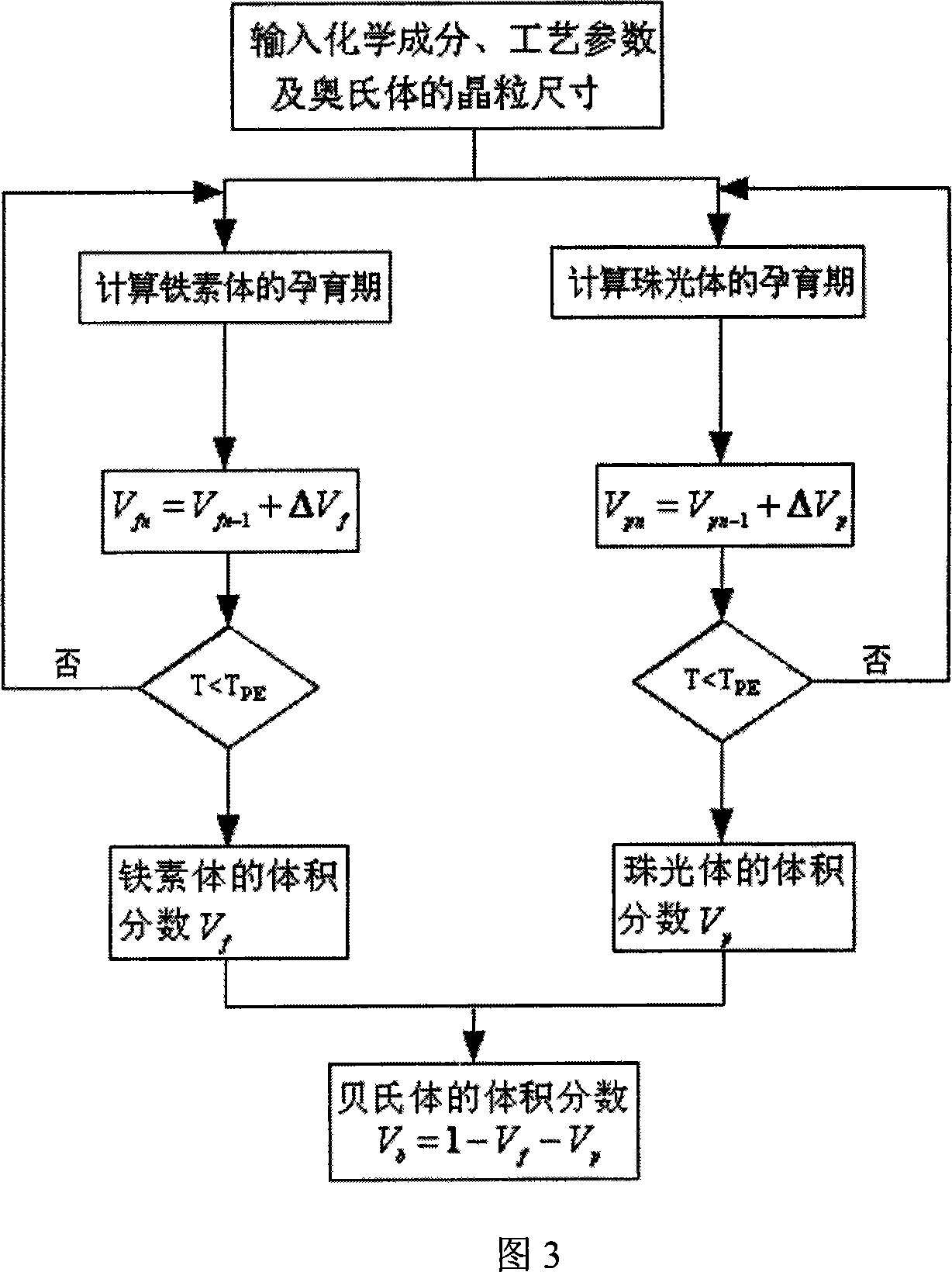

[0159] First, the temperature model is established by the finite difference method, including the temperature model of the rolled piece on the roller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com