Process and device for removing phosphorus and metal impurities in polycrystalline silicon

A technology of metal impurities and polysilicon, applied in chemical instruments and methods, non-metallic elements, silicon compounds, etc., can solve the problems of low primary conversion rate, high energy consumption, long process time, etc., to save energy, improve purity, and install simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

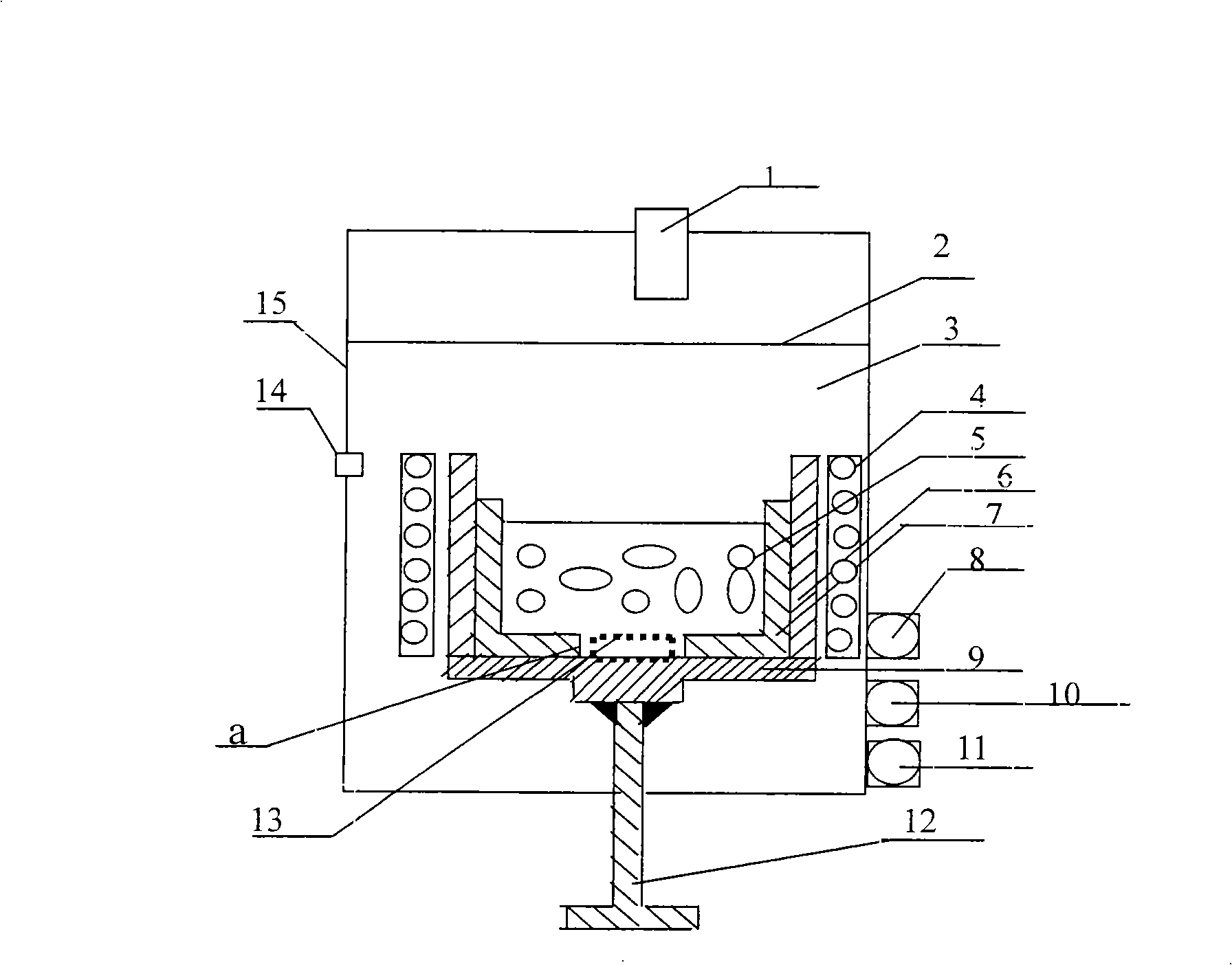

[0019] Specific embodiments of the solution will be described in detail below in conjunction with the technical solution and accompanying drawings.

[0020] Spread silicon powder 13 with a high purity of 99.9999% on the water-cooled copper base 9 and fill the hollow space a of the quartz crucible 7 . Put the polysilicon material 5 with a purity of 99.8% in which impurity phosphorus content is 0.005%, iron content is 0.1254%, and aluminum content is 0.0342% into a quartz crucible 7, and the vacuum device cover 2 is closed. In the vacuuming process, the vacuum chamber 3 is first pumped to a low vacuum 10 with a mechanical pump 8 and a Rhodes pump 10. -0 pa, then use diffusion pump 11 to pump the vacuum to high vacuum 10 -3 below pa. Set the power to 10kW to energize the induction coil 4, and the temperature reaches 1500°C to melt all the silicon material. Preheat the electron gun 1 with 100mA, preheat the beam for 5 minutes, turn off the beam of the electron gun 1, then reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com