Method and device for removing foreign matter of phosphor in polysilicon

A polysilicon and impurity technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of stirring and turning, low conversion rate at one time, and long process time, so as to save energy, improve purity, and install simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

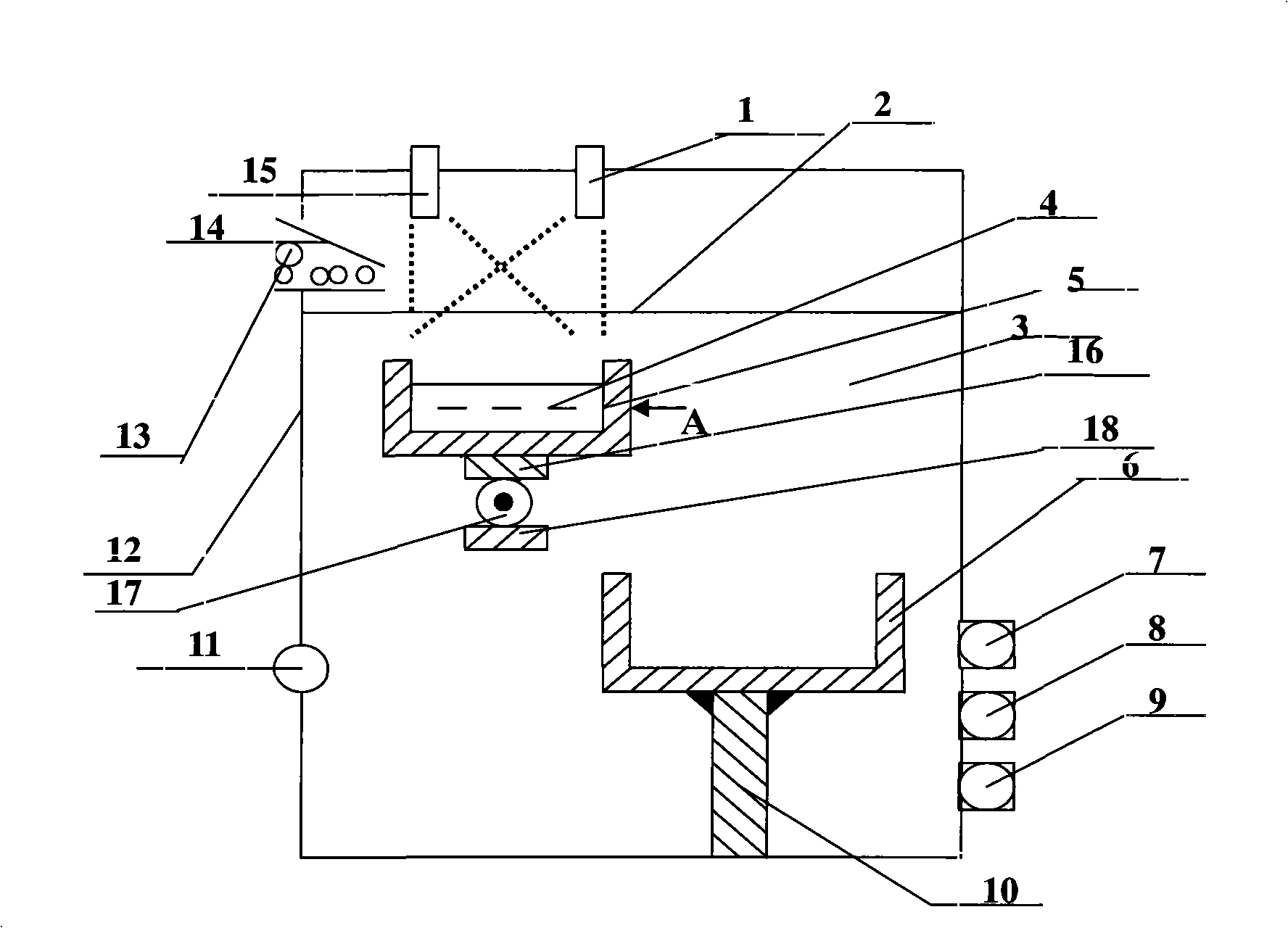

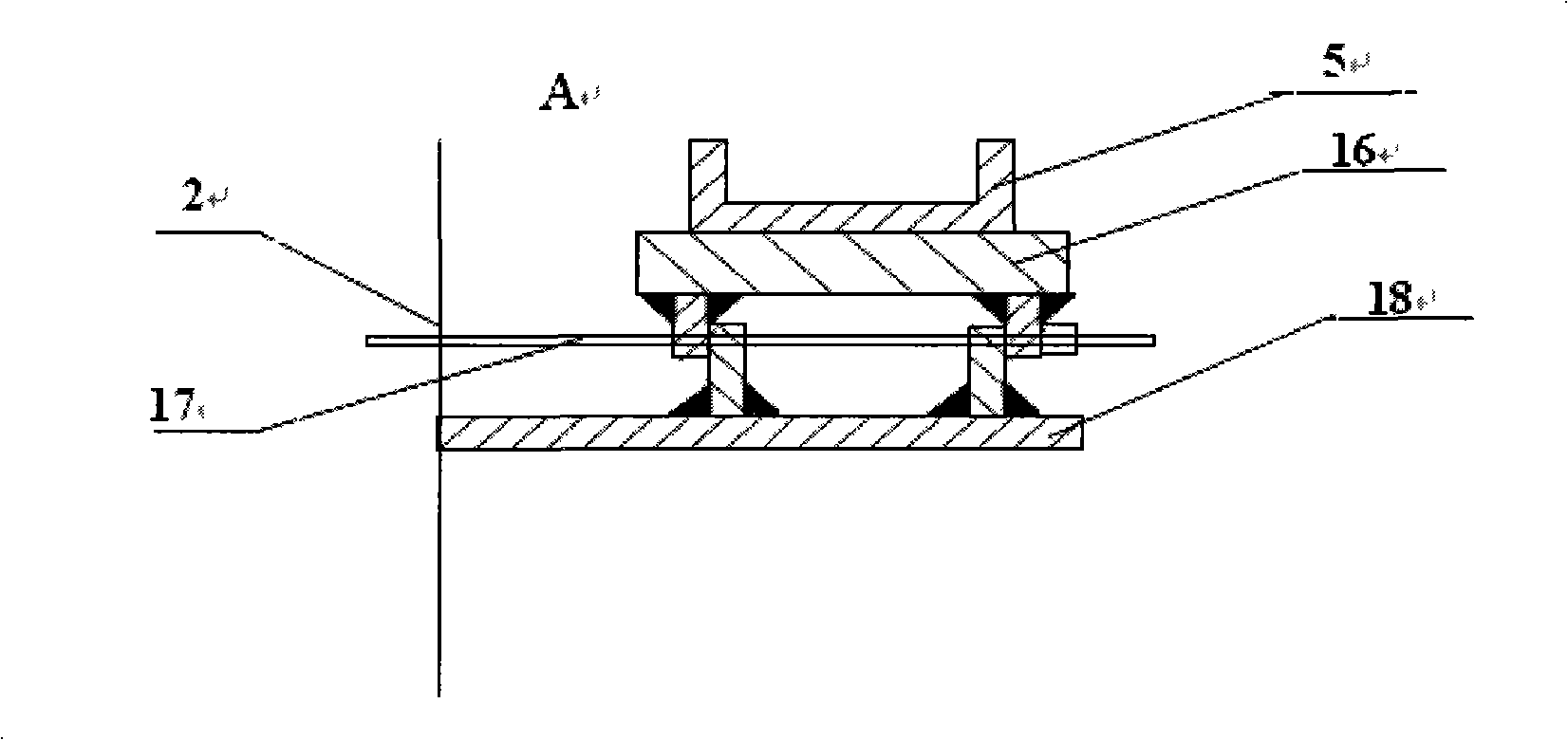

[0017] Specific embodiments of the solution will be described in detail below in conjunction with the technical solution and accompanying drawings.

[0018] The polycrystalline silicon with a purity of 99.8% and a content of impurity phosphorus of 0.005% is loaded into the water-cooled copper crucible 5 with the polycrystalline silicon material 4, the amount of polycrystalline silicon is one-third of the water-cooled copper crucible 5, and the vacuum device cover 2 is closed . To carry out the vacuum process, first use the mechanical pump 7 and the Rhodes pump 8 to pump the vacuum chamber 3 to a low vacuum 10 -0 pa, and then use the diffusion pump 9 to pump to high vacuum 10 -3 below pa; preheat the left electron gun 15 and right electron gun 1, set the high voltage to 25kW, preheat the high voltage for 5 minutes, turn off the high voltage, set the beam current of the left electron gun 15 and right electron gun 1 to 100mA, preheat the beam for 5 minutes, turn off the left El...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com