Phosphorus diffusion method for physical metallurgy polycrystalline silicon solar cell

A technology of solar cells and physical metallurgy, applied in the field of diffusion process, can solve problems such as limited degree of optimization, and achieve the effect of reducing efficiency loss, improving cell crystal structure deterioration, and good diffusion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

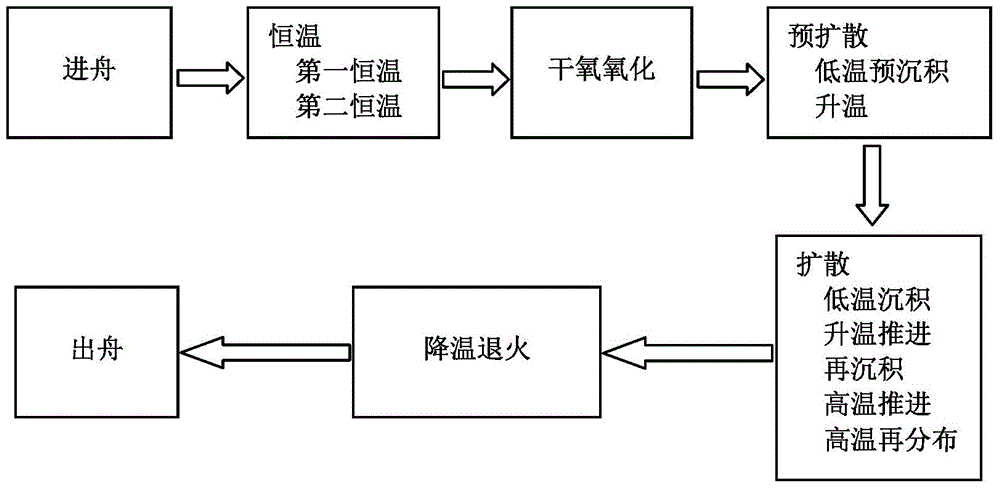

Method used

Image

Examples

Embodiment 1

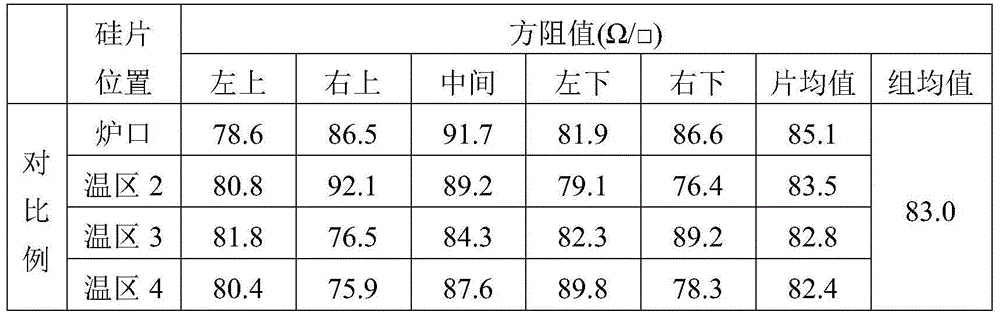

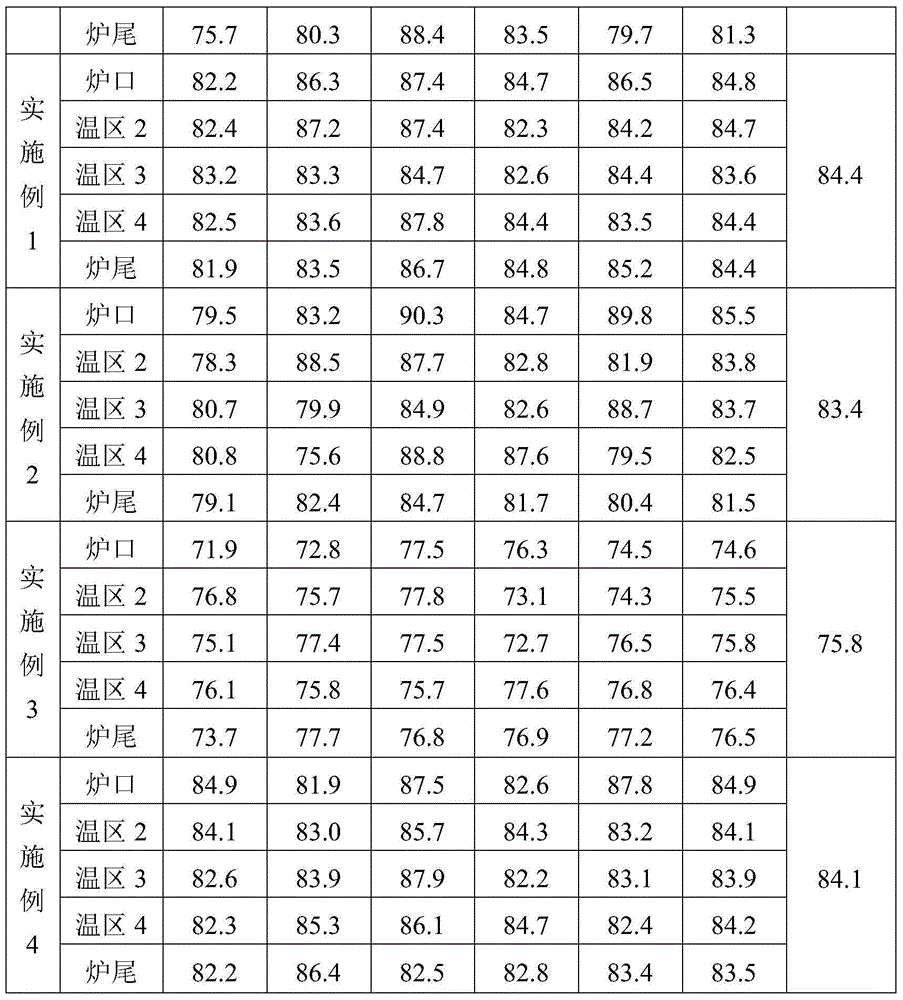

[0086] On the basis of the traditional process comparison example, the optimized two-step constant temperature technology of the present invention was adopted. As Example 1, 400 physical metallurgical polysilicon wafers with suede surfaces were cleaned and placed in a diffusion furnace for protection and diffusion. The target square resistance is 85Ω, which includes the following steps:

[0087] into the boat

[0088] After texturing, the silicon wafers enter the diffusion furnace. During the process of entering the silicon wafers into the boat, large nitrogen is introduced into the air inlet pipe of the diffusion furnace. The large nitrogen flow is 24000sccm, and the boat entry time is 640s;

[0089] constant temperature heat treatment

[0090] The first constant temperature heat treatment: set the temperature of each temperature zone in the quartz tube to: 815 °C at the furnace mouth, 740 °C in the second temperature zone, 730 °C in the third temperature zone, 710 °C in the...

Embodiment 2

[0102] On the basis of the traditional process comparison example, the diffusion step of the present invention is used alone. As Example 2, 400 physical metallurgical polysilicon wafers with suede surfaces are cleaned and placed in a diffusion furnace for protection and diffusion. The diffusion target square resistance is 85Ω , which includes the following steps:

[0103] into the boat

[0104] After texturing, the silicon wafers enter the diffusion furnace. During the process of entering the silicon wafers into the boat, large nitrogen is introduced into the air inlet pipe of the diffusion furnace. The large nitrogen flow is 24000sccm, and the boat entry time is 640s;

[0105] constant temperature

[0106] The temperature of each temperature zone in the quartz tube is set to: 790 °C at the furnace mouth, 788 °C in the second temperature zone, 786 °C in the third temperature zone, 785 °C in the fourth temperature zone, and 785 °C at the furnace tail. The maximum nitrogen flo...

Embodiment 3

[0123] The 400 pieces of physical metallurgical polycrystalline silicon wafers with suede surfaces are cleaned and placed in a diffusion furnace for protection and diffusion. The diffusion target square resistance is 75Ω, which includes the following steps:

[0124] into the boat

[0125] The silicon wafers after texturing enter the diffusion furnace. During the process of entering the silicon wafers into the boat, large nitrogen is introduced into the air inlet pipe of the diffusion furnace.

[0126] constant temperature

[0127] The first constant temperature heat treatment: the temperature of each temperature zone in the quartz tube is set to: 785 °C at the furnace mouth, 720 °C in the second temperature zone, 710 °C in the third temperature zone, 670 °C in the fourth temperature zone, and 783 °C at the furnace end, and keep it during the constant temperature process. Introduce large nitrogen, the large nitrogen flow is 20000sccm, and the constant temperature time is 280s....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com