Phosphorus Diffusion Method for Physical Metallurgical Polysilicon Solar Cells

A technology of solar cells and physical metallurgy, which is applied in the field of diffusion technology, can solve problems such as limited optimization, and achieve the effects of reducing efficiency loss, low surface impurity concentration, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

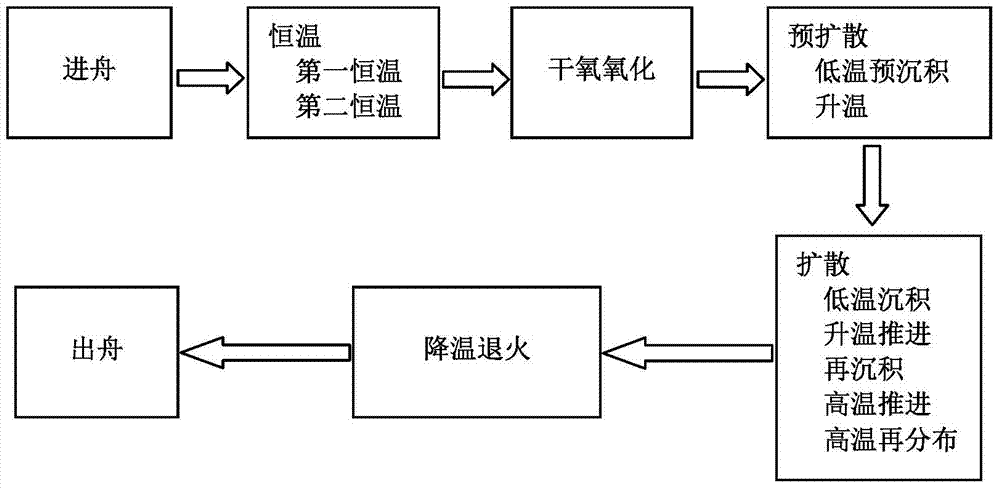

Method used

Image

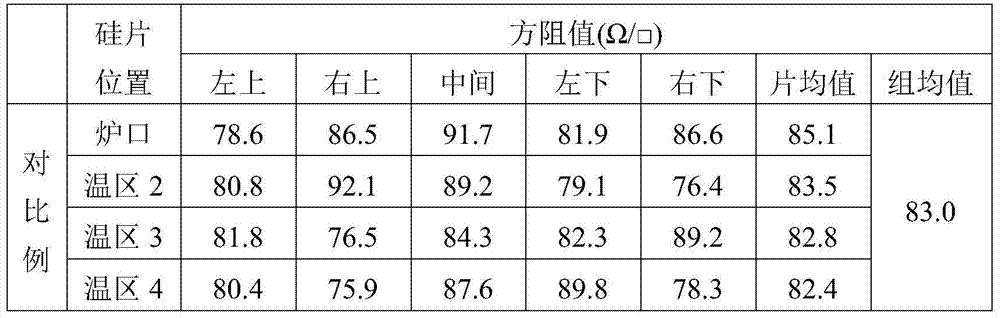

Examples

Embodiment 1

[0086] The optimized two-step constant temperature technology of the present invention is adopted on the basis of the comparative example of the traditional process. As Example 1, 400 physical metallurgical polysilicon wafers made of suede are cleaned and placed in a diffusion furnace for protection and diffusion. The target square resistance is 85Ω, which includes the following steps:

[0087] into the boat

[0088] Textured silicon wafers enter the diffusion furnace. During the process of silicon wafers entering the boat, a large amount of nitrogen is introduced into the inlet pipe of the diffusion furnace. The maximum nitrogen flow rate is 24000 sccm, and the time for entering the boat is 640s;

[0089] constant temperature heat treatment

[0090] The first constant temperature heat treatment: set the temperature of each temperature zone in the quartz tube as follows: furnace mouth 815°C, temperature zone 2 740°C, temperature zone 3 730°C, temperature zone 4 710°C, furnace...

Embodiment 2

[0102] Using the diffusion step of the present invention alone on the basis of the comparative example of the traditional process, as Example 2, 400 physical metallurgical polysilicon wafers made of suede are cleaned and placed in a diffusion furnace for diffusion, and the diffusion target square resistance is 85Ω , including the following steps:

[0103] into the boat

[0104] Textured silicon wafers enter the diffusion furnace. During the process of silicon wafers entering the boat, a large amount of nitrogen is introduced into the inlet pipe of the diffusion furnace. The maximum nitrogen flow rate is 24000 sccm, and the time for entering the boat is 640s;

[0105] constant temperature

[0106] Set the temperature of each temperature zone in the quartz tube as follows: furnace mouth 790°C, temperature zone 2 788°C, temperature zone 3 786°C, temperature zone 4 785°C, furnace tail 785°C, keep feeding large nitrogen during the constant temperature process, The maximum nitroge...

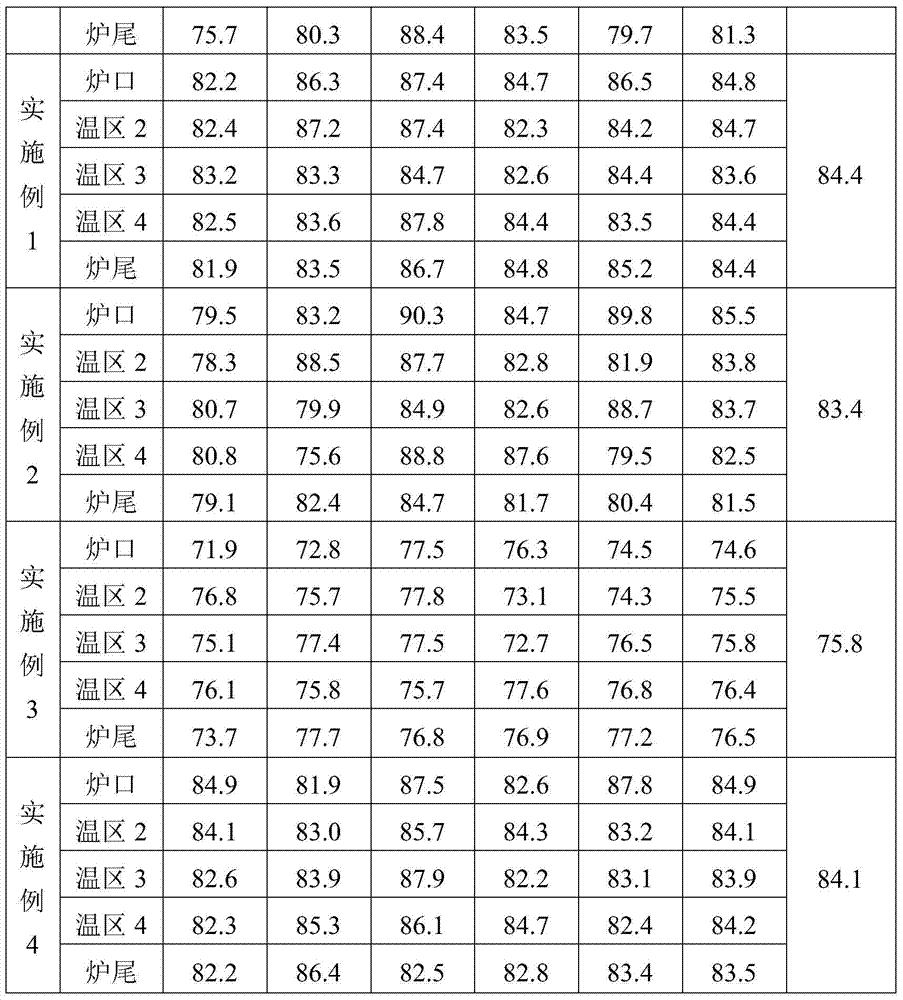

Embodiment 3

[0123] 400 pieces of physical metallurgical polysilicon wafers with suede surface were cleaned and placed in a diffusion furnace for diffusion. The target square resistance of diffusion was 75Ω, which specifically included the following steps:

[0124] into the boat

[0125] Textured silicon wafers enter the diffusion furnace. During the process of silicon wafers entering the boat, large nitrogen is introduced into the inlet pipe of the diffusion furnace. The maximum nitrogen flow rate is 23000 sccm, and the boat entry time is 640s.

[0126] constant temperature

[0127] The first constant temperature heat treatment: set the temperature of each temperature zone in the quartz tube as follows: furnace mouth 785°C, temperature zone 2 720°C, temperature zone 3 710°C, temperature zone 4 670°C, furnace tail 783°C, keep the temperature during the constant temperature process Introduce large nitrogen, the maximum nitrogen flow rate is 20000 sccm, and the constant temperature time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com