Method and device for synchro controlling high precision screwdown at two side during rolling steel plate

A high-precision synchronous and synchronous control technology, applied in rolling mill control devices, hydraulic program control, metal rolling, etc., can solve problems such as reduction speed errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. High-precision pressing synchronous control method and device on both sides of the rolled plate

[0025] The technical content of this embodiment includes two parts: one is the high-precision pressing synchronous control device on both sides of the rolling plate, and the other is the high-precision pressing synchronous control method on both sides of the rolling plate.

[0026] 1. High-precision pressing synchronous control device on both sides of the rolled plate

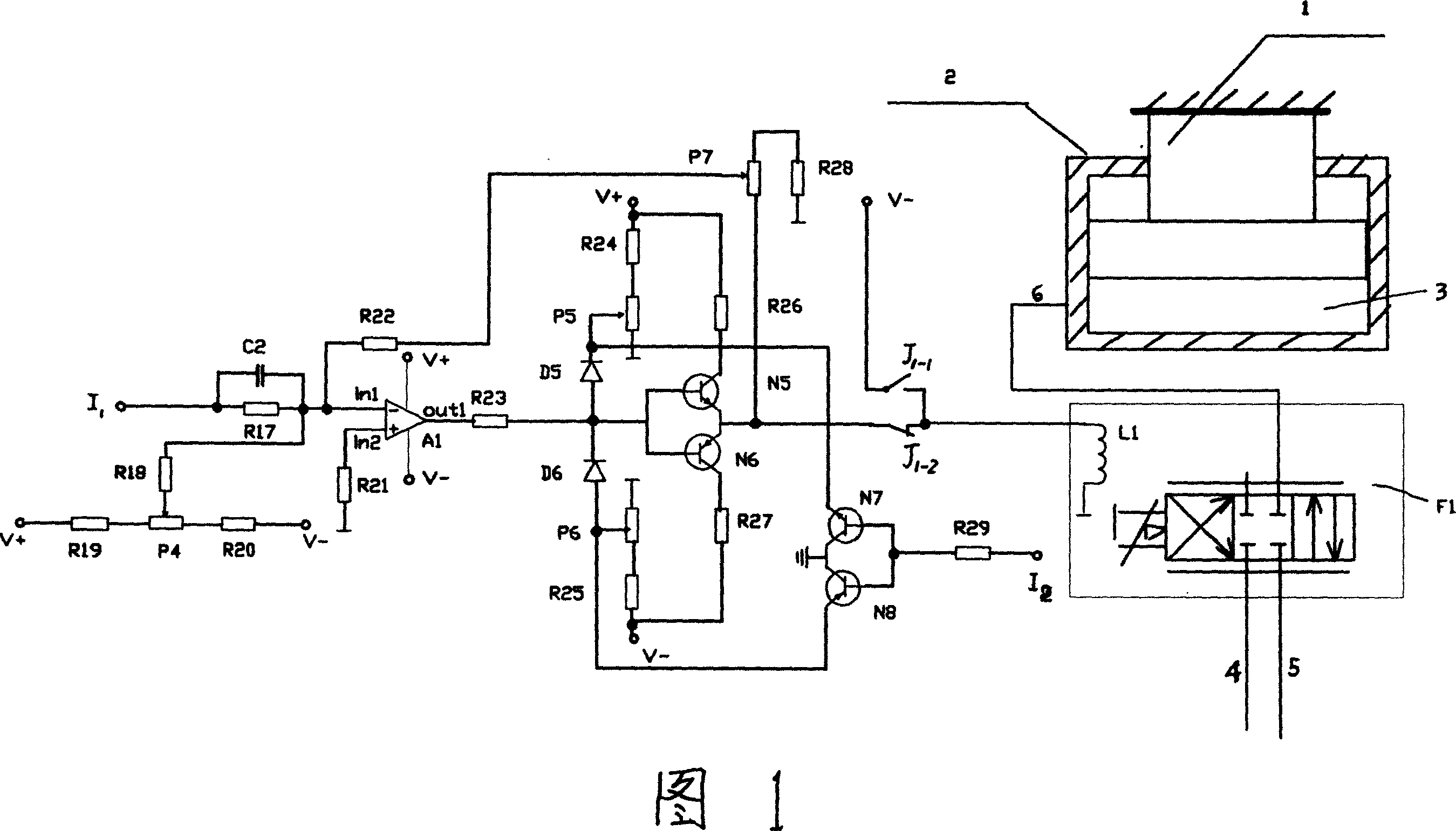

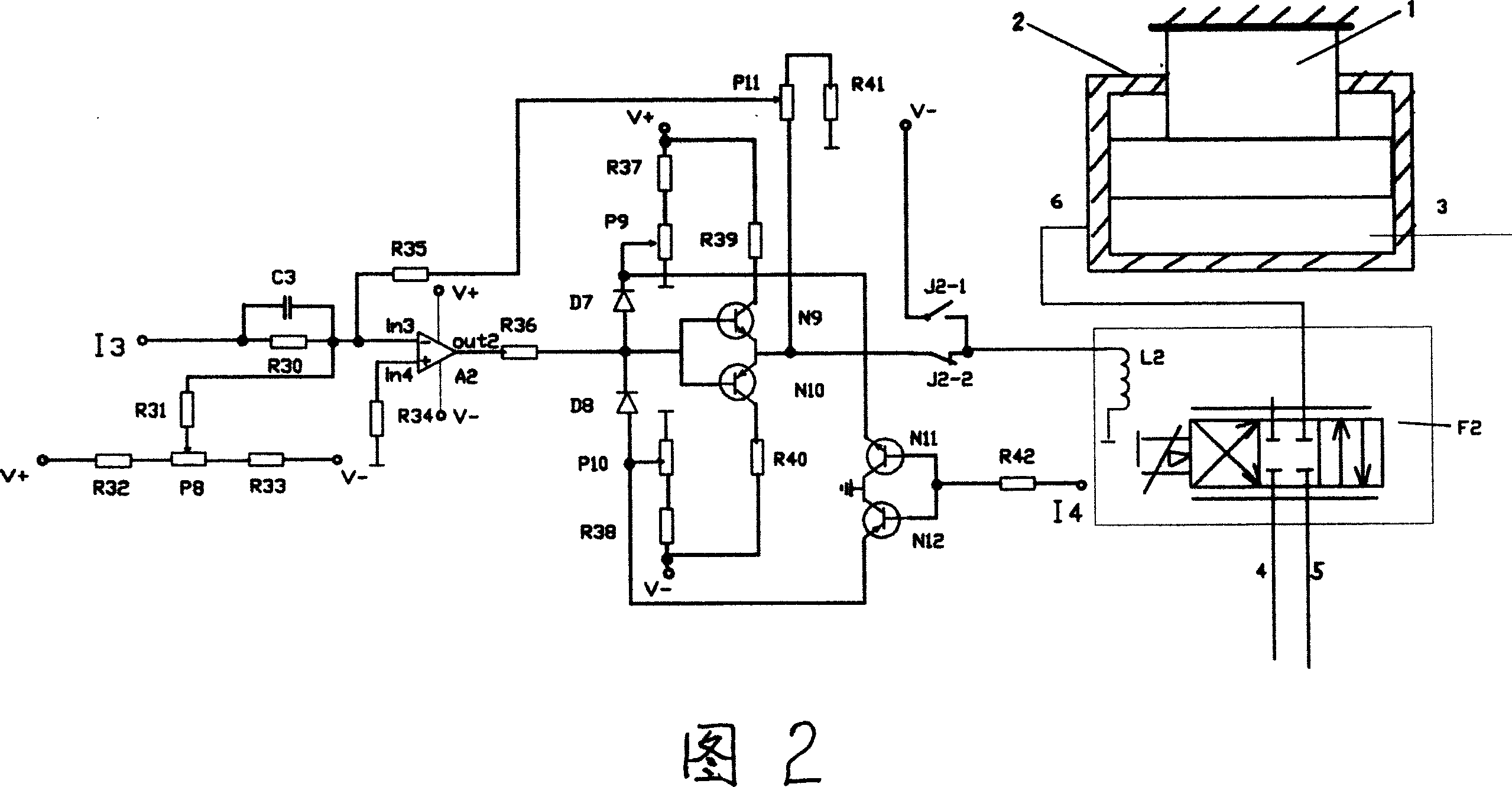

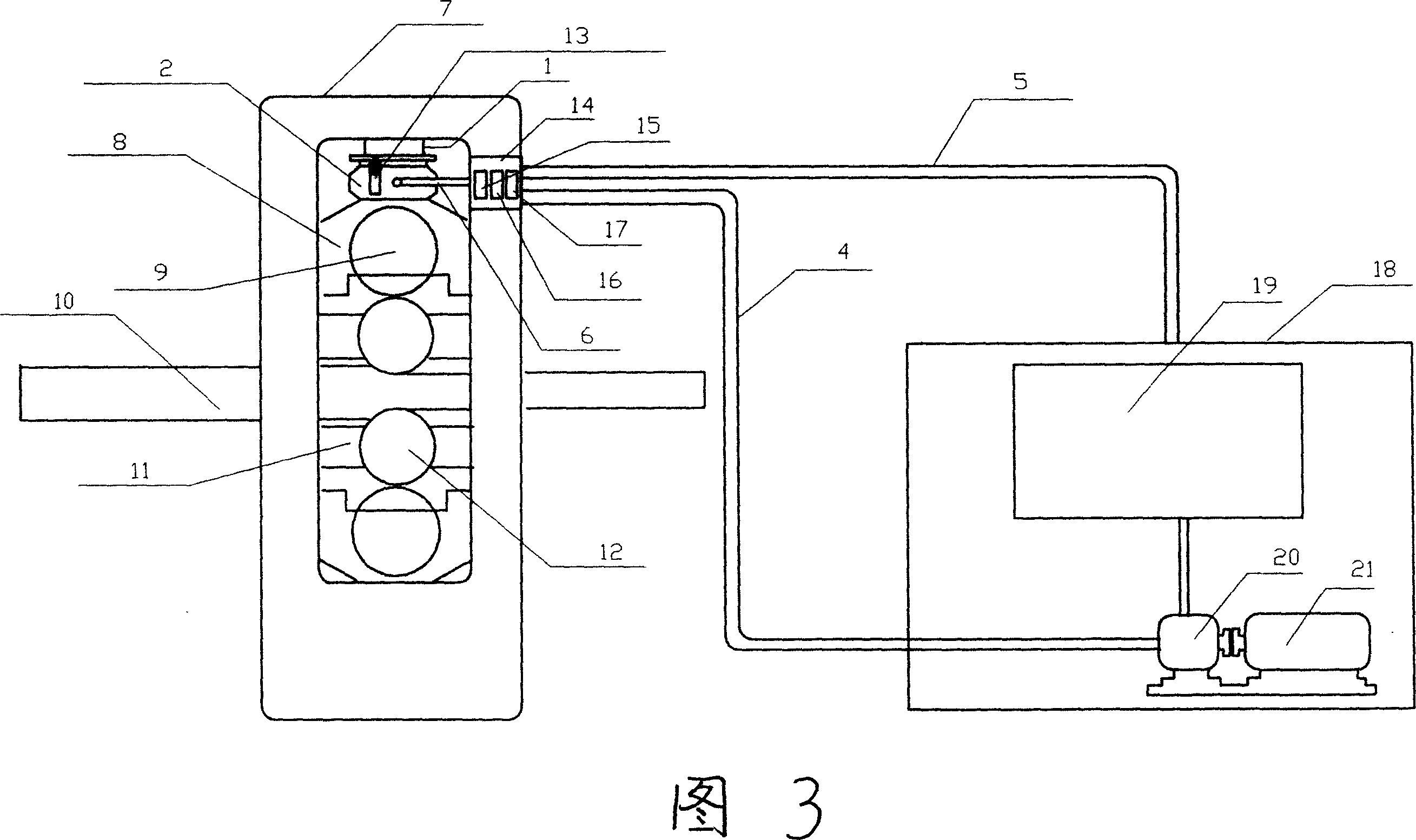

[0027] The specific structure of the high-precision reduction synchronous control device on both sides of the rolled plate in this example is jointly shown in Figures 1 to 3. The technical features of the control device are: the high-precision pressing synchronous control device on both sides of the rolling plate in this example is the same two sets of two-stage high-precision pressing speed control mechanisms arranged on the hydraulic mechanisms on both sides of the rolling plate, and the two ...

Embodiment 2

[0031] Embodiment 2. High-precision pressing synchronous control method and device on both sides of the rolled plate

[0032] The technical content of this embodiment includes two parts: one is the high-precision pressing synchronous control device on both sides of the rolling plate, and the other is the high-precision pressing synchronous control method on both sides of the rolling plate.

[0033] 1. High-precision pressing synchronous control device on both sides of the rolled plate

[0034] The general structure of the high-precision reduction synchronous control device on both sides of the rolled plate in this example can be seen in Figures 1 to 3. The difference is: 1. It is set on both sides of the rolled plate to press and control each mechanism with high precision, including two sets of electronic mechanisms with the same structure of the hydraulic mechanism, servo mechanism, action mechanism and two sets of reference control mechanisms of the computer control mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com