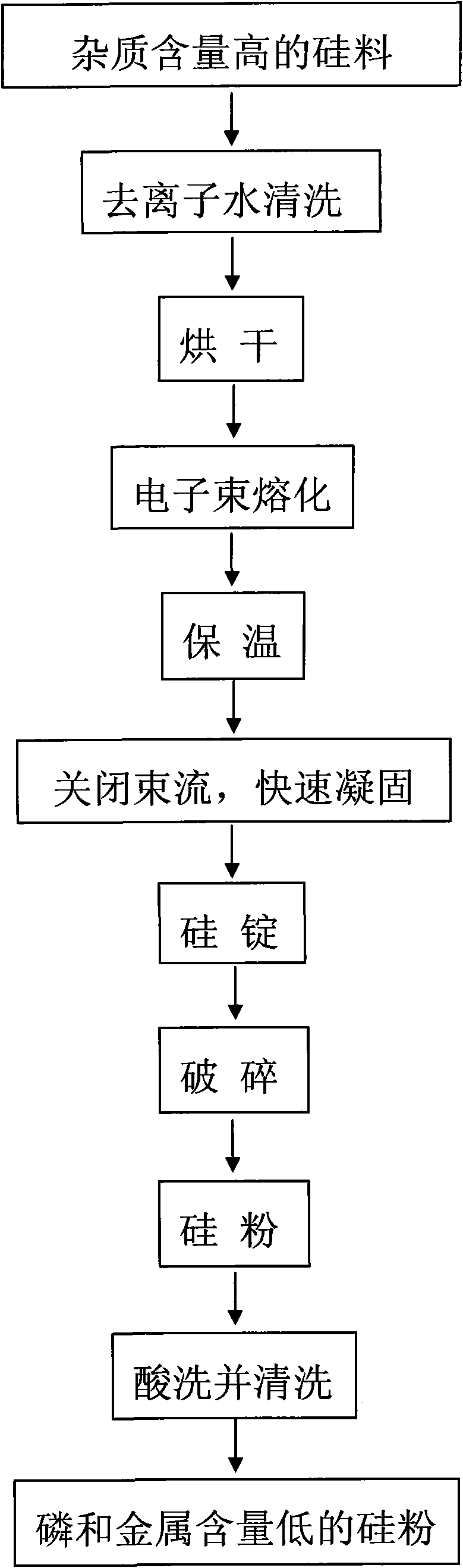

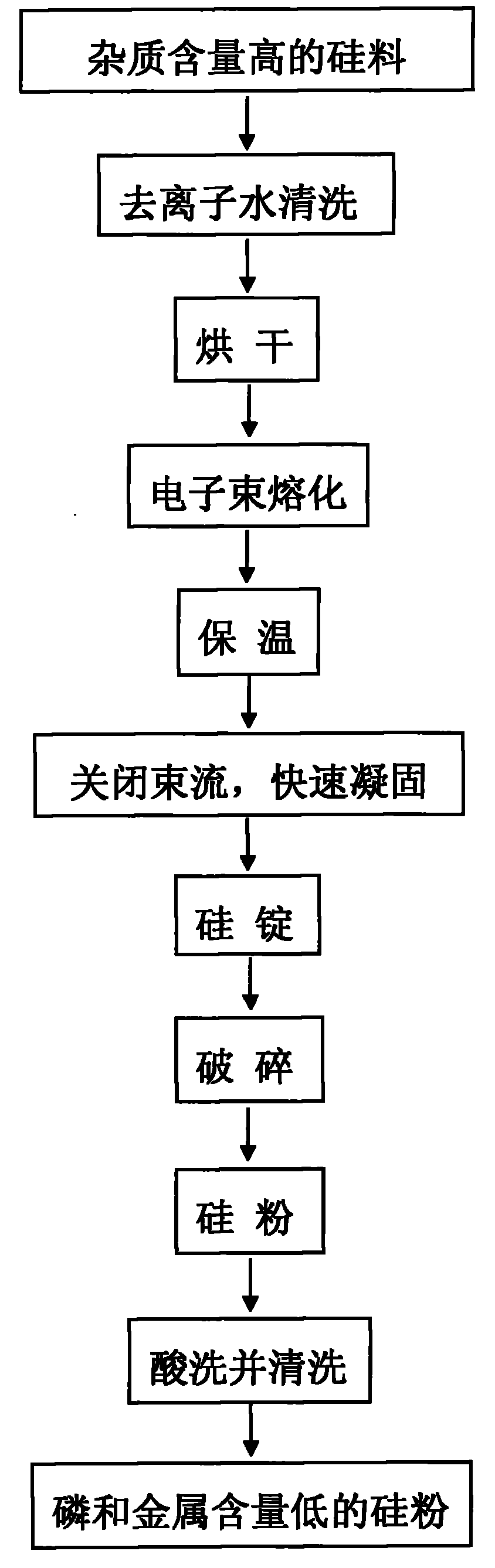

Method for extracting polysilicon through electron beams and acid washing

A technology of polysilicon and electron beams, which is applied in chemical instruments and methods, silicon compounds, sustainable manufacturing/processing, etc., can solve the problems that affect the photoelectric conversion efficiency of solar cells, consume a lot of energy, and cannot remove metal impurities, etc., and achieve purification efficiency High, low energy consumption, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Electron beam smelting technology is one of the most important methods in the metallurgical preparation of solar-grade silicon. In the process of melting silicon material, electron beams provide high-density energy. After the energy is converted into heat, the temperature of silicon material increases, thereby melting the silicon material. , after complete melting, smelting for a certain period of time, the impurity elements in the silicon melt with a small saturated vapor pressure, such as phosphorus, evaporate into gas and are drawn away; after the volatile impurities are removed, the silicon melt solidifies rapidly, and the crystal The grain size tends to be small, and a large number of metal impurities can become the center of non-uniform nucleation, so the silicon ingot will be composed of many fine grains after solidification, the metal impurities are enriched at the grain boundaries of the grains, and the silicon ingot is broken along the grain boundaries Finally,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com