Method for purifying polysilicon through enhanced alloying segregation

A polysilicon and alloying technology, applied in chemical instruments and methods, inorganic chemistry, chemical industry, etc., can solve the problems of environmental pollution, large slag consumption, high energy consumption in plasma refining, and achieve high production efficiency, strong practicability, The effect of short industrial production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

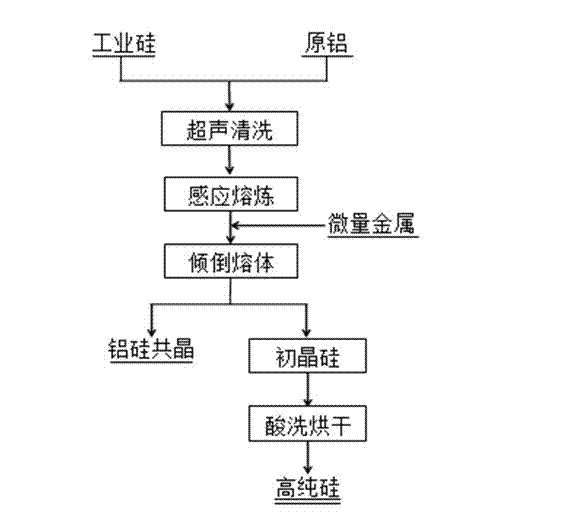

[0026] like figure 1 As shown, a brief process of a method for enhancing alloying segregation to purify polysilicon is as follows: first, pre-treat industrial silicon and primary aluminum, then carry out alloy melting, solidify and purify to obtain primary silicon, and then post-treat the primary silicon , finally get polysilicon with boron content less than 0.2ppmw, the specific operation process is as follows:

[0027] The first step of pretreatment: first take industrial silicon with a purity of 99.0% and a boron content of 25ppmw and primary aluminum with a purity of 99.8%, and perform ultrasonic cleaning with deionized water for 2 hours to remove impurities attached to the surface. The first purpose is to reduce industrial silicon and The content of the original impurities in the original aluminum, the second is to avoid the reaction of some impurities with silicon, which will affect the purification effect;

[0028] The second step of alloying and smelting: Weigh the ra...

Embodiment 2

[0032] like figure 1 As shown, a brief process of a method for enhancing alloying segregation to purify polysilicon is as follows: first, pre-treat industrial silicon and primary aluminum, then carry out alloy melting, solidify and purify to obtain primary silicon, and then post-treat the primary silicon , finally get polysilicon with boron content less than 0.2ppmw, the specific operation process is as follows:

[0033] The first step of pretreatment: first take industrial silicon with a purity of 99.4% and a boron content of 22ppmw and primary aluminum with a purity of 99.7%, and perform ultrasonic cleaning with deionized water for 3 hours to remove impurities attached to the surface. The first purpose is to reduce industrial silicon and The content of the original impurities in the original aluminum, the second is to avoid the reaction of some impurities with silicon, which will affect the purification effect;

[0034] The second step of alloying and smelting: Weigh the ra...

Embodiment 3

[0038] like figure 1 As shown, a brief process of a method for enhancing alloying segregation to purify polysilicon is as follows: first, pre-treat industrial silicon and primary aluminum, then carry out alloy melting, solidify and purify to obtain primary silicon, and then post-treat the primary silicon , finally get polysilicon with boron content less than 0.2ppmw, the specific operation process is as follows:

[0039] The first step of pretreatment: first take industrial silicon with a purity of 99.8% and a boron content of 20ppmw and primary aluminum with a purity of 99.5%, and perform ultrasonic cleaning with deionized water for 4 hours to remove impurities attached to the surface. The purpose is to reduce industrial silicon and The content of the original impurities in the original aluminum, the second is to avoid the reaction of some impurities with silicon, which will affect the purification effect;

[0040] The second step of alloying and smelting: Weigh the raw alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com