Bending and cutting integrated machine and method thereof

A machine and machine equipment technology, applied in the field of bending and cutting integrated machines, can solve the problems of cumbersome processing technology, high cost, low yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

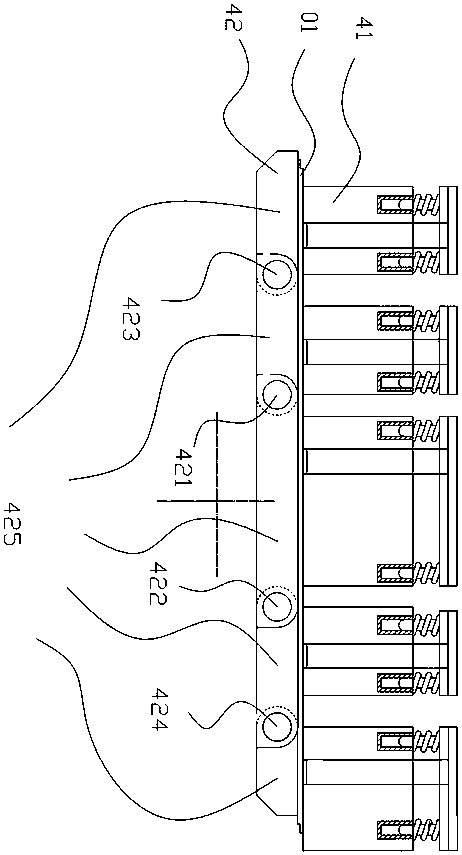

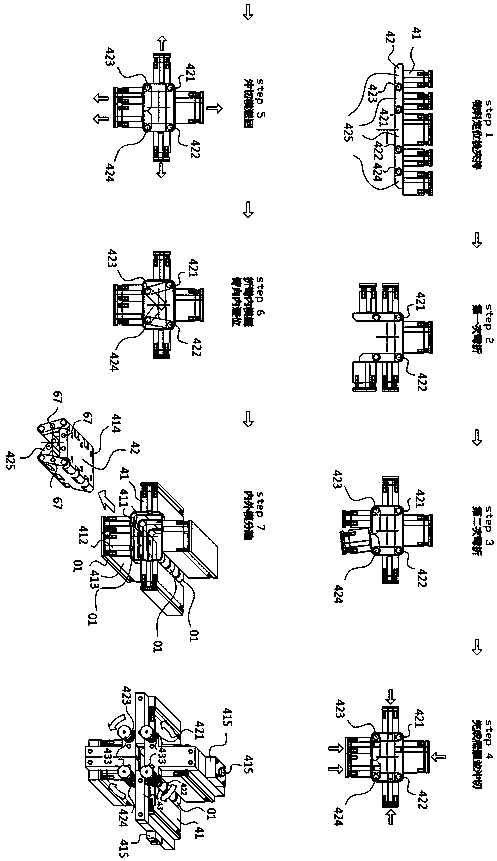

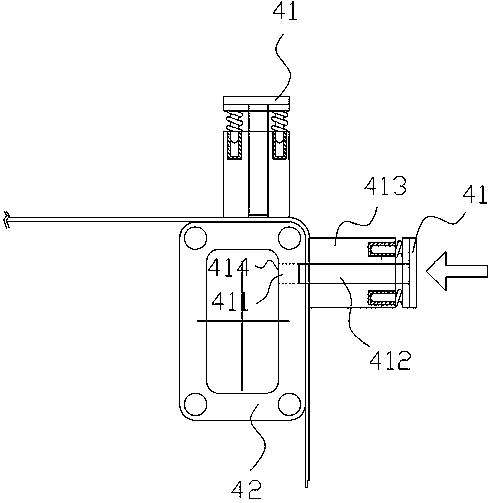

[0081] Combine below Figure 1 to Figure 23 , the present invention is further described:

[0082] Such as Figure 1-Figure 3 As shown, the present invention relates to an integrated bending and cutting machine and method. The innovation of the bending and cutting integrated machine and method is that it is provided with a bending and cutting integrated machine equipment 055, on which one or more A bending outer mold 41 and a bending inner mold 42 corresponding to the bending angle are fixed on the machine body or the movable mechanical arm or the rotation axis or the guide rail, that is, the machine equipment 055 is connected with the bending outer mold 41 and the bending inner mold respectively. The mold 42 is fixedly locked on the machine equipment 055 through a movable connection device or a fixed connection device, and one or more bending angles are provided with a corresponding rotation axis 421-424, and the rotation axes 421-424 are horizontal to each other Or / and arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com