Method for load test of single beam

A load test, single-piece beam technology, applied in the testing of machine/structural components, special data processing applications, measuring devices, etc., can solve the problems of low reliability and inconvenient measurement, and achieve accurate results and direct evaluation methods. Effect

Active Publication Date: 2016-08-17

HUNAN LIANZHI BRIDGE & TUNNEL TECH

View PDF8 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The purpose of the present invention is to provide a single beam load test method to solve the tec

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

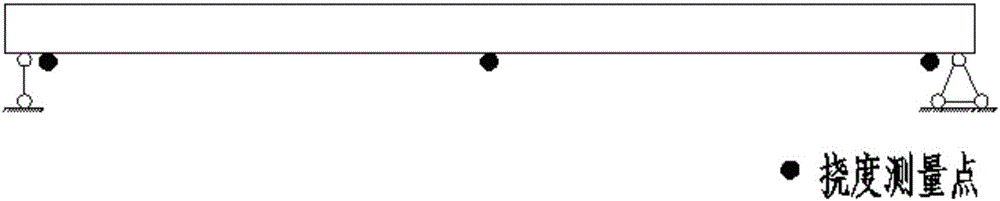

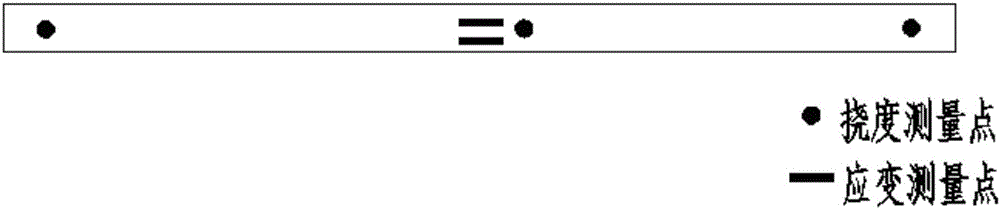

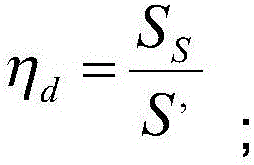

The invention provides a method for a load test of a single beam. The method comprises the steps of placing 1-2 test elements on each measuring point of a test beam body, wherein the measuring points comprise center positions of the bottom surfaces of the two ends of the beam body and the central position of the bottom surface of a length midpoint of the beam body; performing preloading and stepping loading on the test beam body until a loaded load reaches a calculated control stress value; after a last stage of load is loaded, standing for 15-30 min and reading values; performing classified unloading of all test loads, performing structural deformation recovery for about 30 min, reading the values again to serve as structural residual deformation values, and calculating check coefficient, relative residual displacement and relative residual strain. The novel method for testing the single beam is provided; in the load test, with the beam bottom stress delta=0 as a test control objective, by measurement of deflection and beam bottom stress in the testing process and observation of beam bottom cracking conditions, the beam bottom prestress degree can be directly reflected, and thus prestress tension construction quality of a beam plate is evaluated.

Description

technical field [0001] The invention relates to the technical field of bridge construction, in particular to a single-piece beam load test method which can directly judge the quality of prestressed construction. Background technique [0002] At present, the commonly used test methods for monolithic beams (both refer to prestressed concrete beams) are mainly based on the regulations in the "Regulations for Testing and Evaluation of Bearing Capacity of Highway Bridges" (JTG / T J21-2011), through controlling the internal force and strain of monolithic beams. Or the principle of displacement equivalent to determine the efficiency of static load test, through graded loading, and then through crack observation, static load test structure verification coefficient ζ, the relative residual displacement or relative residual strain S'p of the main measuring points to judge the beam slab stress state. In the test process, the internal force is controlled as the equivalent principle, and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M99/00G06F17/50

CPCG01M99/007G06F30/13

Inventor 梁晓东唐登波李君唐艳陈绪林邓屹松

Owner HUNAN LIANZHI BRIDGE & TUNNEL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com