Rolling reduction acquisition method and device for upper-row rollers of roller-type stretch bend straightening machine

A technology of tension straightening and acquisition method, which is applied in the field of metallurgy, can solve the problems that are not conducive to improving the shape of strip steel, can not take into account the straightening and scale breaking of strip steel, and the surface scratches of strip steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

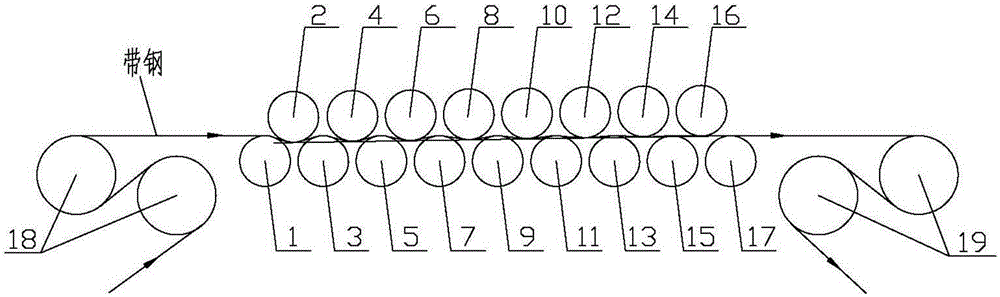

[0067] Taking the seventeen-roll stretch bending straightening machine of a certain steel plant as an example, the method of the present invention is used to calculate the reduction amount of each upper row of rollers, and then use the calculation result as a set value to set the reduction position of each upper row of rollers , the accuracy and reliability of the method of the present invention can be verified by observing the running conditions of the steel strip on site.

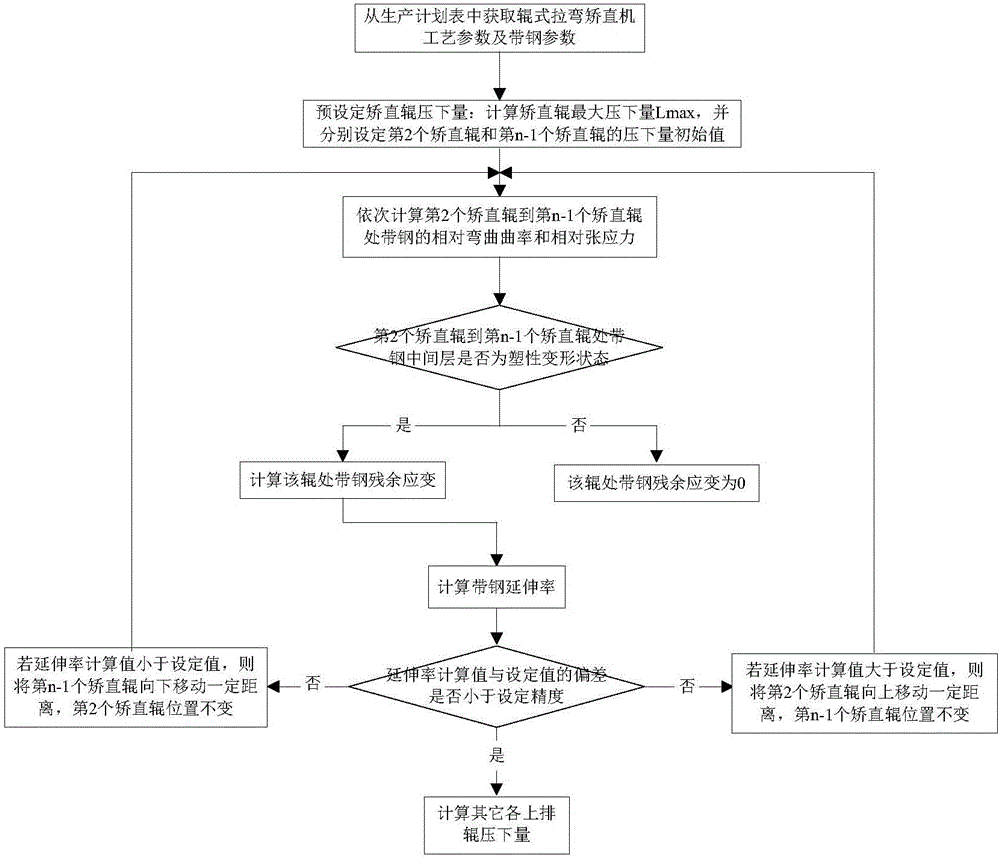

[0068] figure 2 The process flow of a method for obtaining the rolling reduction of the upper row of rolls of a roll-type stretch bending straightening machine provided by an embodiment of the present invention specifically includes the following steps:

[0069] (1) The parameters of the seventeen-roller stretch-bending straightening machine and the strip steel parameters of 5 working conditions were obtained from the production schedule, wherein the number of straightening rollers n=17, the diameter of ...

Embodiment 2

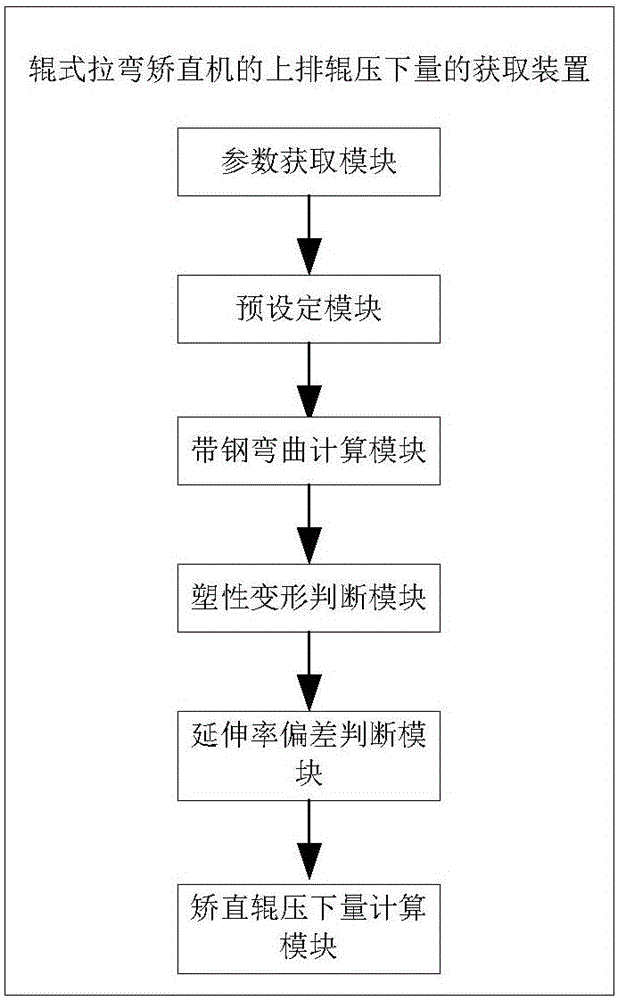

[0100] image 3 It is a structural diagram of an acquisition device for the rolling reduction of the upper row of rollers of a roller-type stretch bending straightening machine provided by an embodiment of the present invention. The device for obtaining the reduction of the upper row of rolls of a roll-type stretch bending straightening machine provided in this embodiment includes:

[0101] The parameter obtaining module is used to obtain the technical parameters of the roller-type stretch bending straightening machine and the strip steel parameters from the production schedule, and the technical parameters of the straightening machine specifically include the number n of straightening rollers, the diameter of straightening rollers d (unit mm) and roller distance t (in mm), the line speed of the entrance tension roller group v 0 and the line speed of the exit tension roller group v 1 , the strip parameters specifically include steel category, strip thickness h (unit mm), str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com