Device and method for measuring three-dimensional distribution of residual stress in metal microstructure

A technology of metal microstructure and residual stress, applied in the direction of material analysis using radiation diffraction, etc., can solve the problems of poor measurement accuracy, large workload, inability to carry out, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

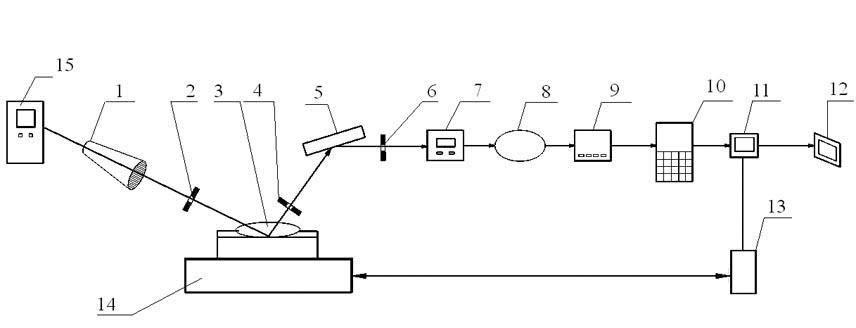

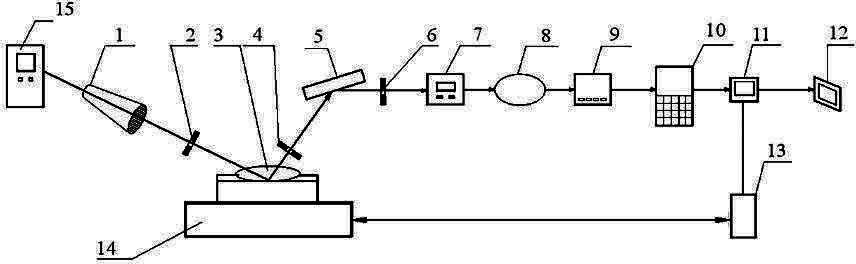

[0034] Such as figure 1 A device for measuring the three-dimensional distribution of residual stress in metal microstructures shown includes: an X-ray generating system, a micro-diffraction and optical path guiding system, a workbench system, a detection system, a computer and a control system. The X-ray tube in the X-ray generating system is a short-wavelength X-ray tube, and the anode target is made of copper, or molybdenum, or A9, or tungsten; a synchrotron radiation source 15 is used in the X-ray generating system. The micro-diffraction and optical path guiding system includes: the micro-diffraction and optical path guiding system includes: a tapered capillary 1, an exit slit 2, an anti-scattering slit 4, a plane monochromator 5 and a receiving slit 6; the detection system includes : detector 7, amplifier 8, pulse height analyzer 9, counter 10; the workbench system is a precision three-dimensional platform with grating that can move in X, Y and Z three-dimensional directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com