Direct fitting determination method of gas content of coal seam

A measurement method and technology of coal seam gas, which is applied in the field of measurement of coal mine gas content, can solve the problems of large influence, error, and long time consumption, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

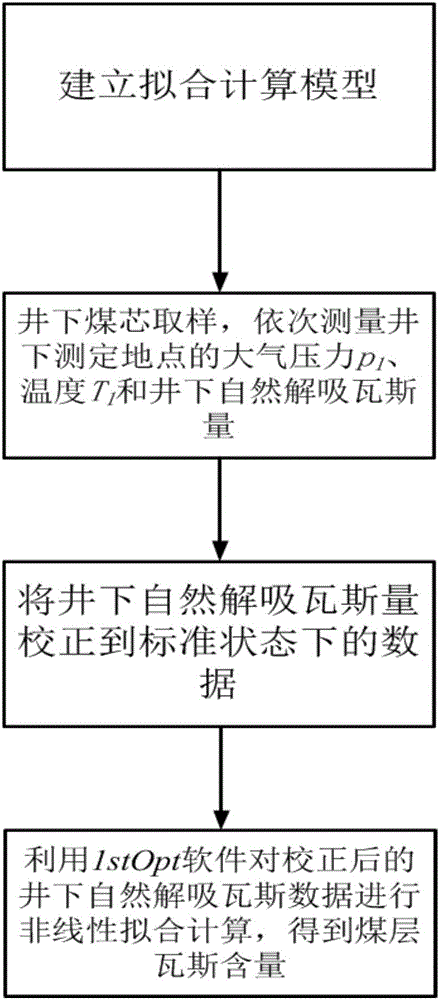

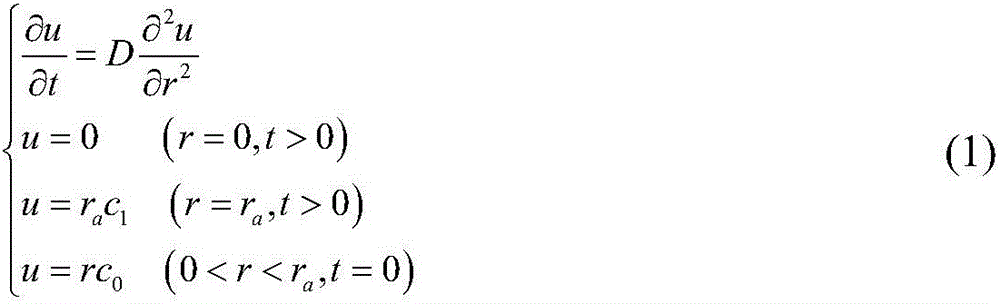

Method used

Image

Examples

Embodiment 1

[0083] According to "GB 474-2008 Coal Sample Preparation Method", "GB / T 212-2008 Coal Industrial Analysis Method", "GB / T 19560-2008 Coal High Pressure Isotherm Adsorption Test Method" and other methods, the Songjiagou Coal Mine in Shaanxi was analyzed. (SX), Inner Mongolia Bayangol Coal Mine (NMG), Xinjiang Jinta Dahuangshan Coal Mine (XJ), Feicheng Caozhuang Coal Mine (CZ), Heze Xinjulong Coal Mine (XJL), Heze Yuncheng Coal Mine (YC), Shanxi Coal Mine Coal samples from Yuquan Coal Industry (YQ), Huainan Panyidong Mine (PYD) and Guizhou Tongzi Coal Mine (TZ) were processed and analyzed to obtain the basic parameters of the coal samples (Table 1).

[0084] Table 1 Basic parameters of coal samples

[0085]

[0086] In order to verify the rationality of the general expression of the gas desorption law of coal samples and the feasibility of the direct fitting measurement method of coal seam gas content, the non-linear fitting was carried out on the gas desorption data of 9 kind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com