Method for measuring residual stress on surface of metal sample based on micro indentation

A residual stress and micro-indentation technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, testing the hardness of materials, etc. Accurate measurement, flexible and lightweight test instruments, and convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 2A02 Aluminum Alloy Tower Quenching Residual Stress Test.

[0032] The 2A02 aluminum alloy tower was kept at 470°C for 2 hours, and then quickly quenched in water at room temperature to introduce quenching residual stress.

[0033] 1) Uniaxial tensile test of 2A02 aluminum alloy

[0034] The material is processed into a standard tensile sample according to the national standard, and the normal temperature uniaxial tensile test is carried out on the MTS810 universal testing machine to obtain the normal temperature stress-strain curve of the 2A02 aluminum alloy material. After calculation and fitting, its strength coefficient = 899.19MPa can be obtained , The strain hardening exponent n=0.25.

[0035] 2) Surface treatment and labeling of tower parts

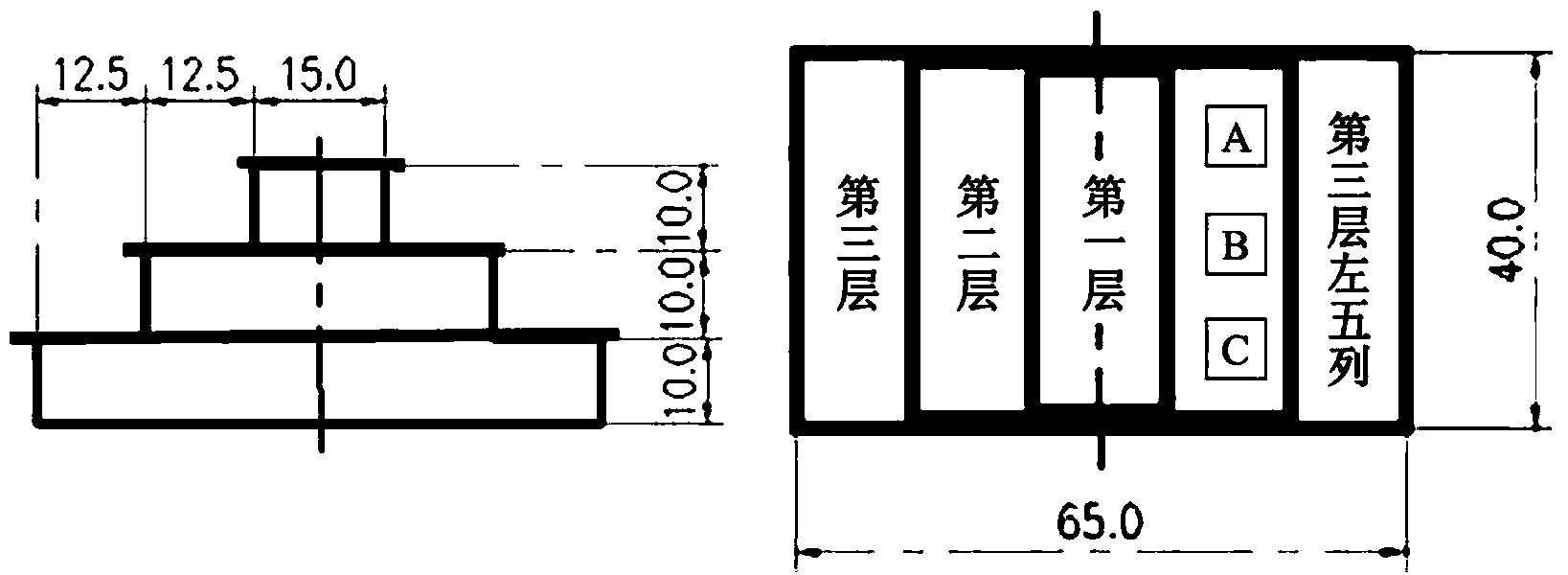

[0036] The shape of the tower is as figure 1 shown. Grinding and polishing the surface, care must be taken not to use too much force when grinding and polishing, so as to avoid destroying the original residual stress fie...

Embodiment 2

[0050] Test of Quenching Residual Stress in 7050 Aluminum Alloy Towers.

[0051] The 7050 aluminum alloy tower was kept at 470°C for 2 hours, and then rapidly quenched in water at room temperature to introduce quenching residual stress.

[0052] 1) Uniaxial tensile test of 7050 aluminum alloy

[0053] The material is processed into a standard tensile sample according to the national standard, and the normal temperature uniaxial tensile test is carried out on the MTS810 universal testing machine to obtain the normal temperature stress-strain curve of the 7050 aluminum alloy material. After calculation and fitting, the strength coefficient = 846.92MPa can be obtained , The strain hardening exponent n=0.22.

[0054] 2) Surface treatment and labeling of tower parts

[0055] The shape of the tower is as figure 1 shown. Grinding and polishing the surface, care must be taken not to use too much force when grinding and polishing, so as to avoid destroying the original residual str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com