Counterforce loading frame for multifunctional self-balancing type continuous beam test

A reaction force loading, self-balancing technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of test error, complicated preparation, and difficulty, and achieve improved accuracy and convenience, convenient and fast installation, The effect of reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

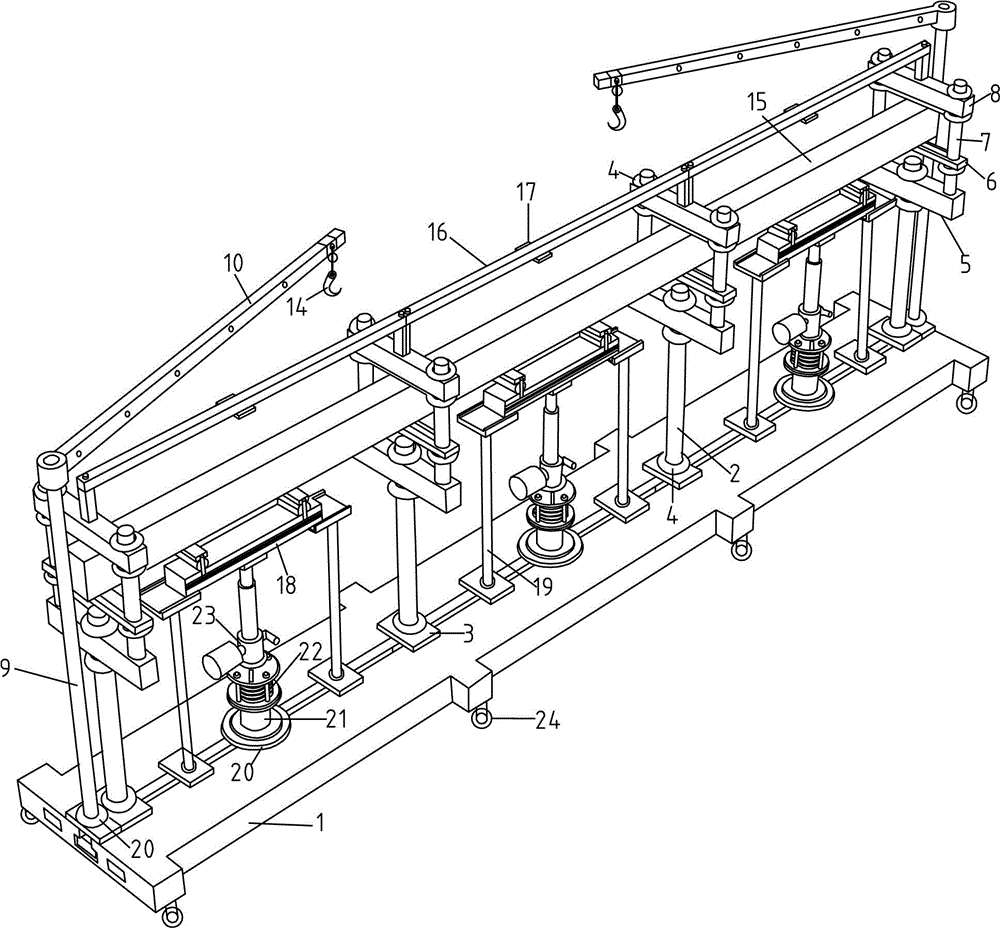

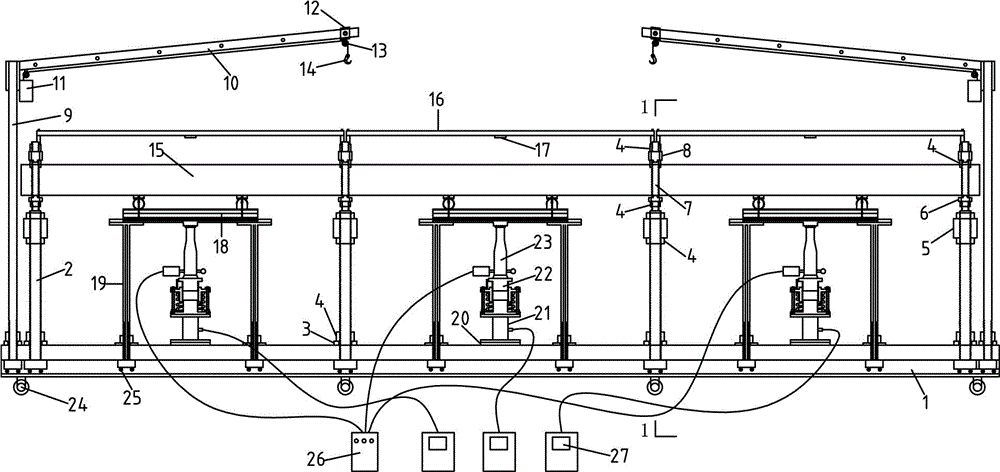

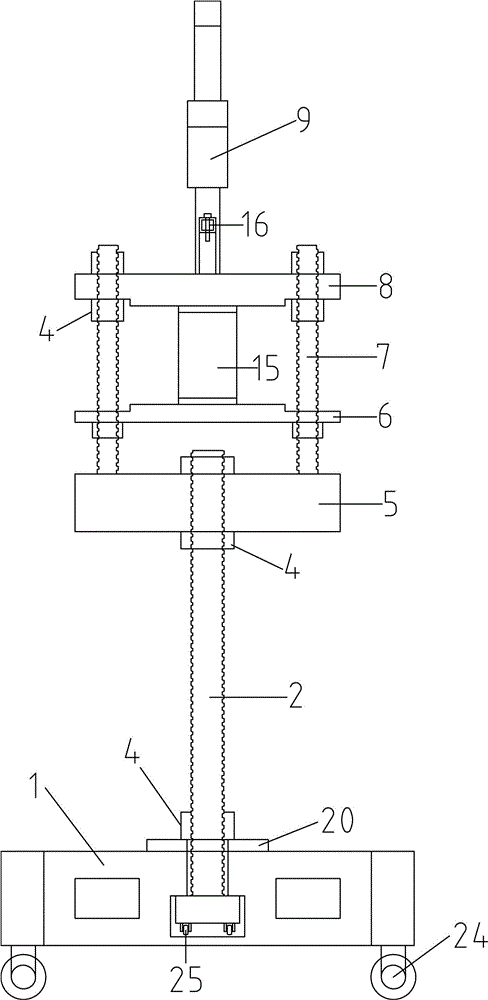

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] see Figure 1-7, a multifunctional self-balancing continuous beam test reaction force loading frame, which includes a reaction force frame bottom plate 1, a Fuma wheel 24 is installed at the bottom of the reaction force frame bottom plate 1, and a longitudinal slide is processed on the middle part of the upper surface of the reaction force frame bottom plate 1 The chute is equipped with an electric lifting device 9, a counter force loading frame column 2 and a distribution beam support 19, and the counter force loading frame column 2 is processed with a full thread and is equipped with a directional wheel 25 at its bottom, and the top is threaded. The lower crossbeam 5 is installed, and the upper top surface of the lower crossbeam 5 is processed with a crossbeam column 7, and the middle beam 6 and the upper beam 8 are fixedly installed on the cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com