32m/900t prestressed concrete pretension box beam static loading test method

A static load test and concrete technology, applied in the field of static load test, can solve the problems of unable to meet the test requirements, unable to design 32m pretensioned box girder, construction technology and construction quality box girder crack resistance and strength performance verification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

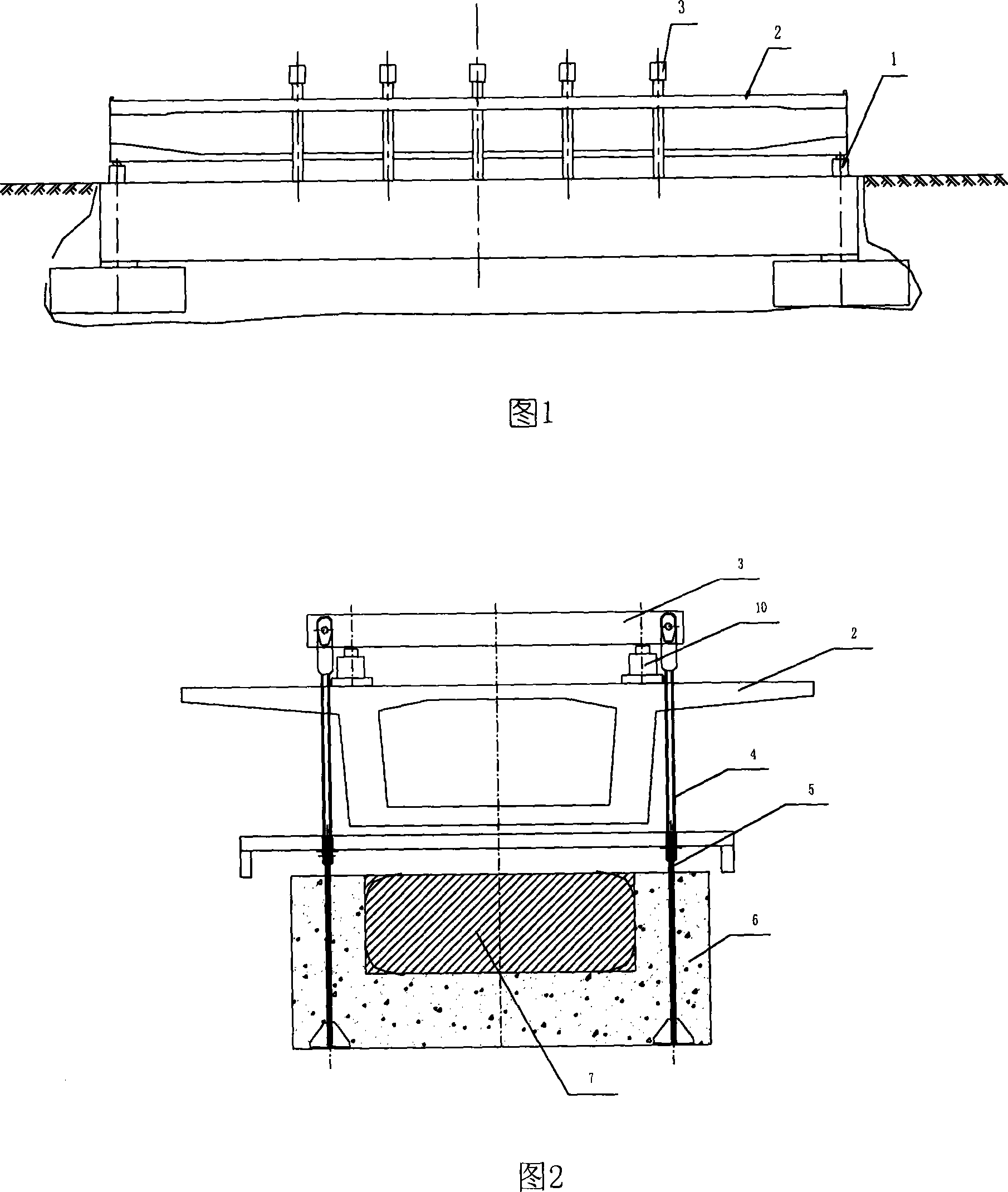

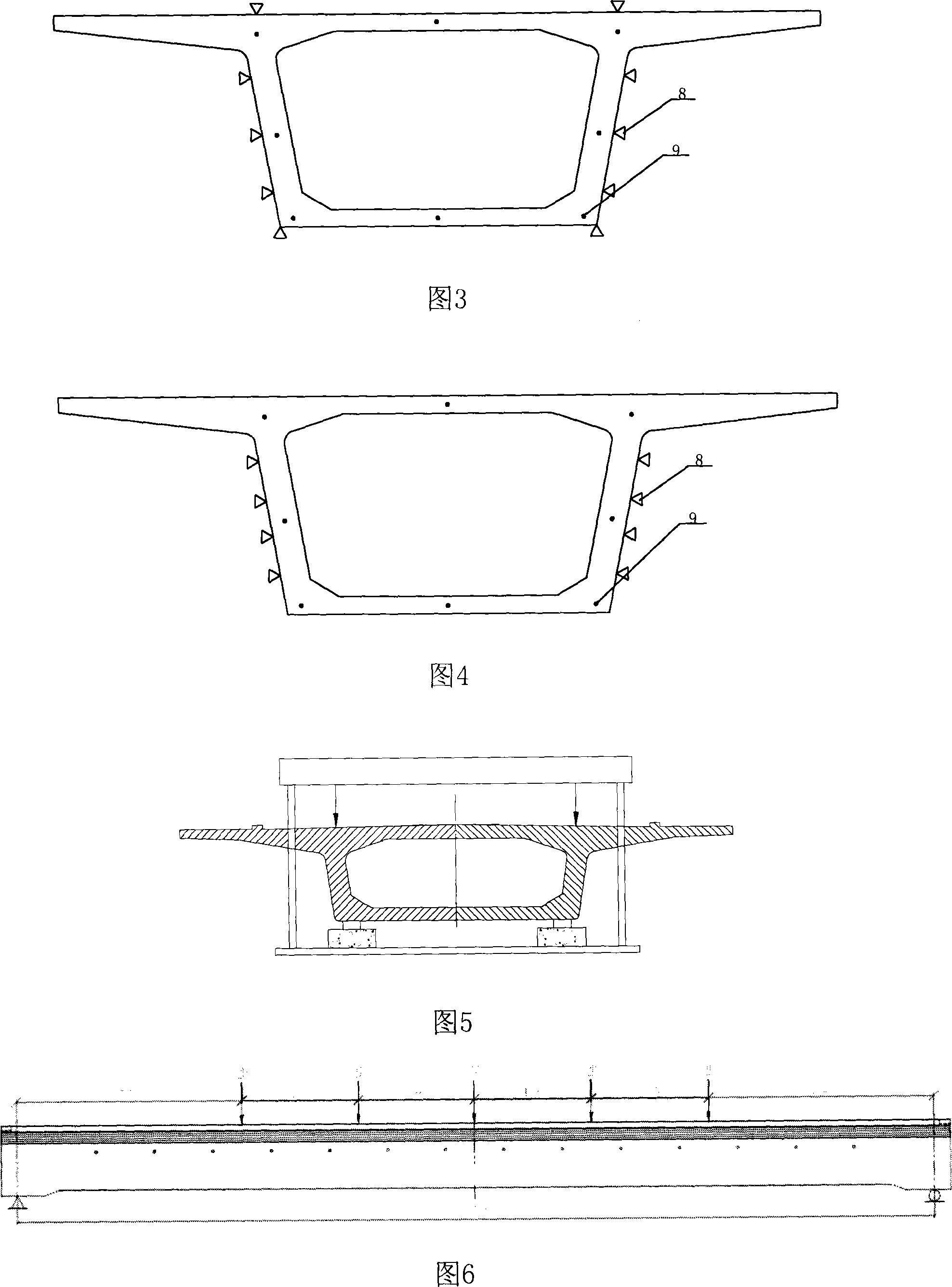

[0018] 32m / 900t prestressed concrete pretensioned box girder static load test method, the test bench includes a test bench 1 with two ends, the test bench 1 is equipped with a foundation beam 6 of reinforced concrete frame structure, and the foundation beam 6 is set for loading counterweight 7 The end beam, the middle beam, and the foundation beam 6 are pre-embedded with anchor rods 5, and the anchor rods 5, suspenders 4 and pole beams 3 are all steel structures connected by bolts, as shown in Figures 1 and 2.

[0019] The test steps are as follows:

[0020] First, lift the counterweight 7 to the end beam between the two foundation beams 6 of the static load test bench, then move the static load test pre-tensioned box girder 2 to the pedestal on the foundation beam 6 and install the support, and pass the tie rod through The test beam body pre-embeds th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com