Hydraulic support balancing mechanism testing device and method

A technology of hydraulic support and balancing mechanism, which is applied to the testing of machine/structural components, measuring devices, mine roof supports, etc., can solve the problem that the balancing mechanism does not have a good test method, and achieve the effect of good verification and reduction of underground accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] The above-mentioned hydraulic support balance mechanism test device of the present invention realizes the method for hydraulic support balance mechanism test, and its preferred specific implementation mode is:

[0021] Include steps:

[0022] Firstly, the cover beam, the front connecting rod, the rear connecting rod and the base of the hydraulic support are fixed to each other;

[0023] Then, first raise the column to make the top beam upward, the balance jack rod chamber is pulled until the safety valve is unloaded and pulled out at least 30mm, then the column is lowered to lower the top beam, and the balance jack piston chamber is pressed until the safety valve is unloaded and is pushed back at least 30mm , The lifting of the column is a cycle, and the total cycle is at least 4000 times.

[0024] Time is used to control the expansion and contraction of the balance jack, and the average time for stretching out 30mm is obtained through experiments to set the time for l...

specific Embodiment

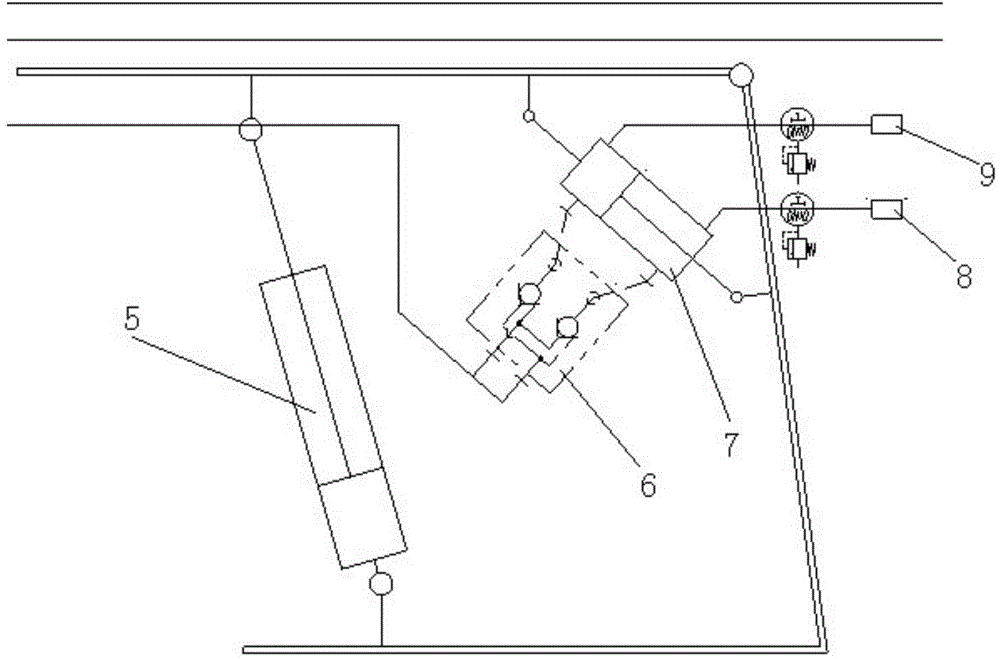

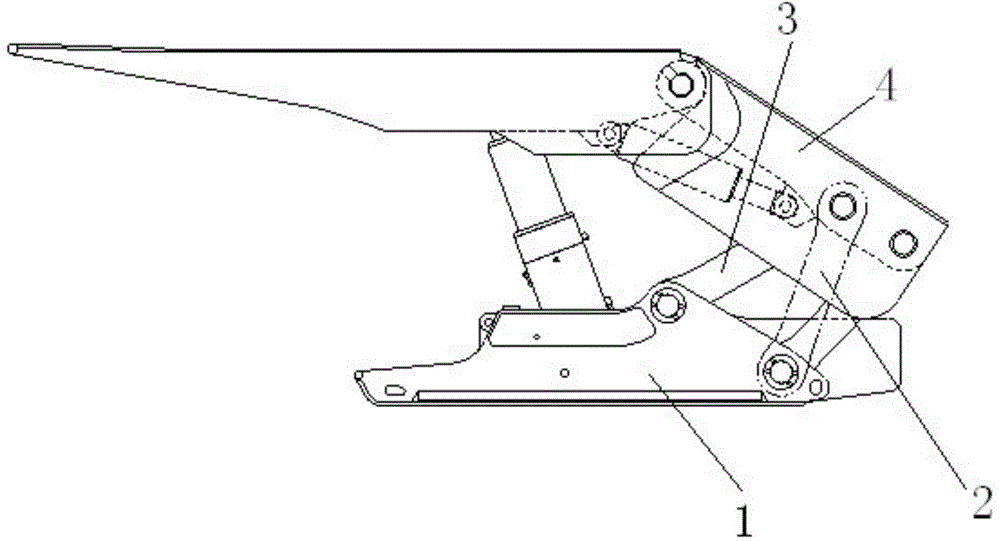

[0026] Such as figure 1 , figure 2 As shown, the rear part of the bracket is properly fixed. Firstly, the column is raised to make the top beam upward, and the rod chamber of the balance jack is pulled until the safety valve is unloaded and pulled out at least 30mm. Unloaded and pressed back at least 30mm. The lifting of the column is a cycle, a total of 4000 cycles.

[0027] According to the limitations of the pipeline system of the test bench, the test bench has no displacement sensor. Consider using time to control the expansion and contraction of the balance jack. The control is: liquid filling-lowering column, pressurization-rising column, the initial support and lowering column respectively replenish the upper and lower chambers of the balance, while the column is raised, the upper chamber of the balance jack is pressurized, the safety valve drains, and the system supplies the lower chamber. When the chamber is replenished with liquid, the balance jack is stretched o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com