Test loading system for tendon connector of tension leg platform

A technology of tension leg platform and loading system, which is applied in the testing of machines/structural components, the use of stable tension/compression to test the strength of materials, and the testing of mechanical components. It can solve the problem that fixed foundations cannot meet the requirements of deep-sea wind energy development. , non-applicability, self-weight and project cost increase, etc., to achieve the effect of verifying fatigue resistance, reliability and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

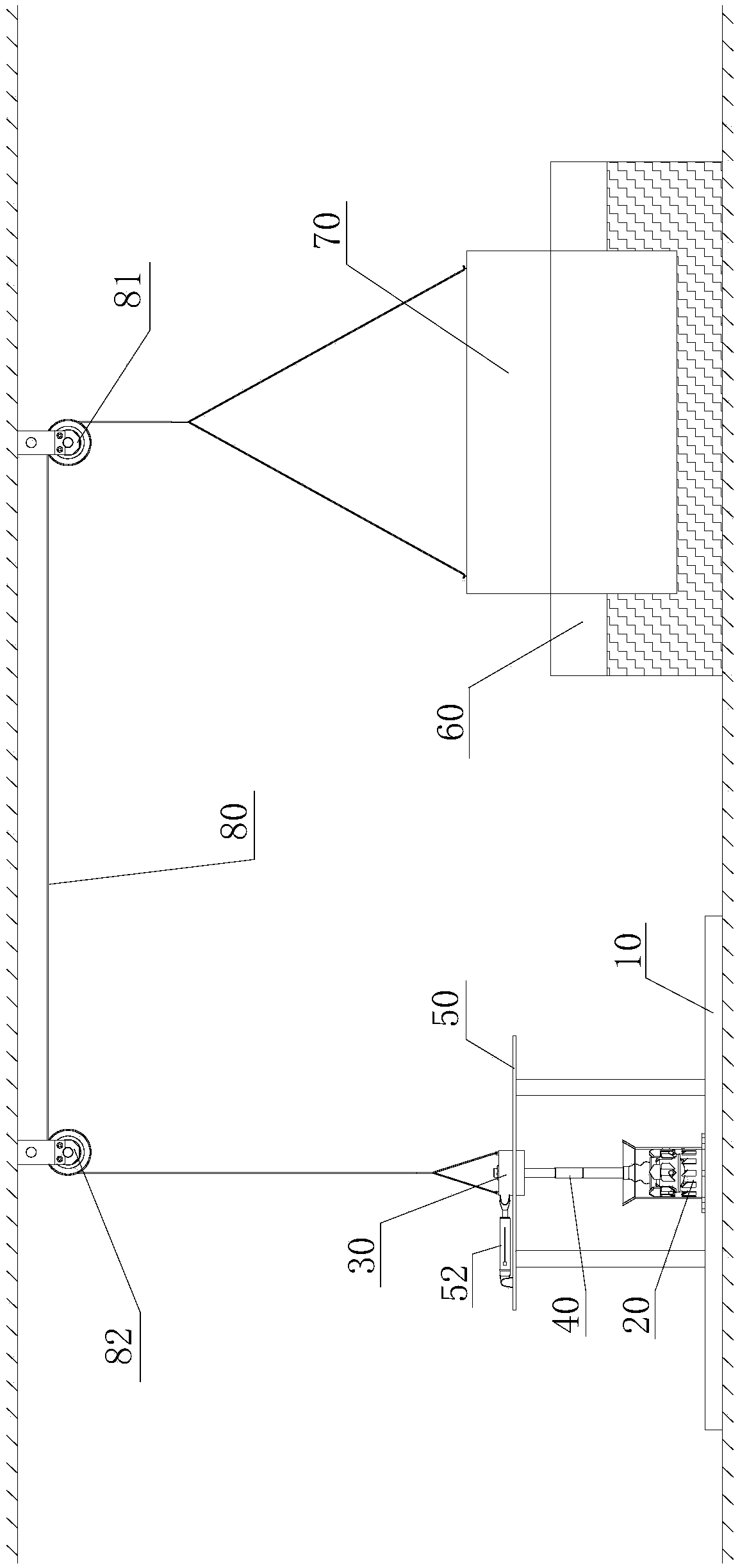

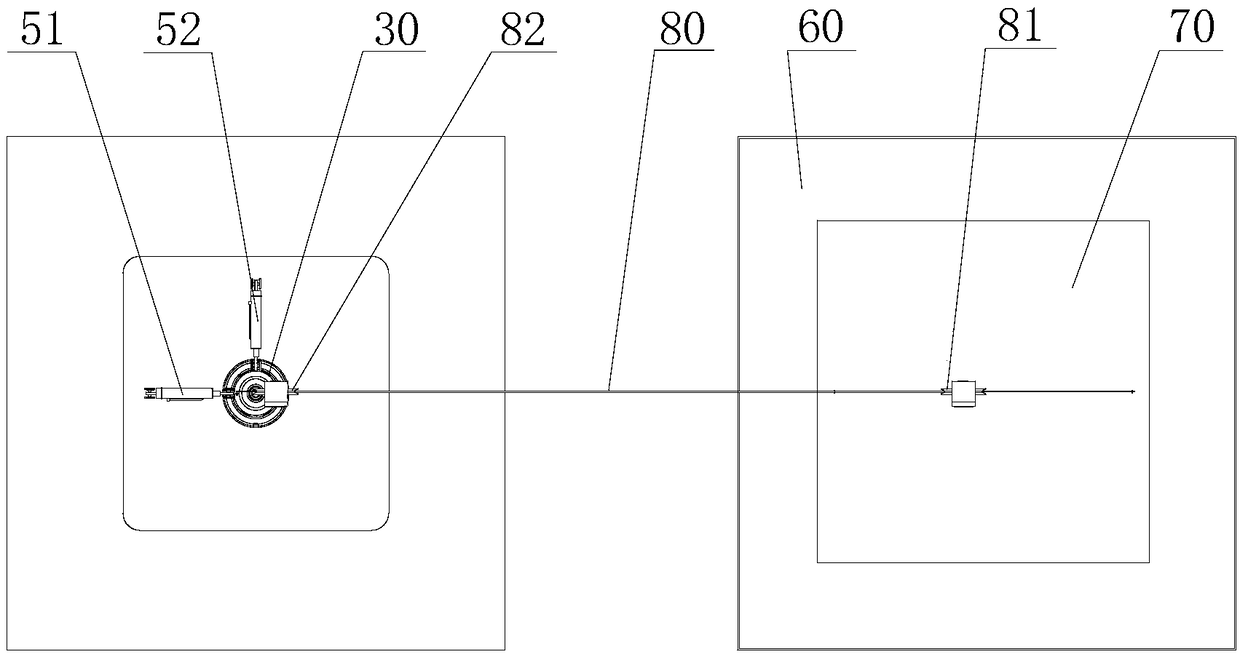

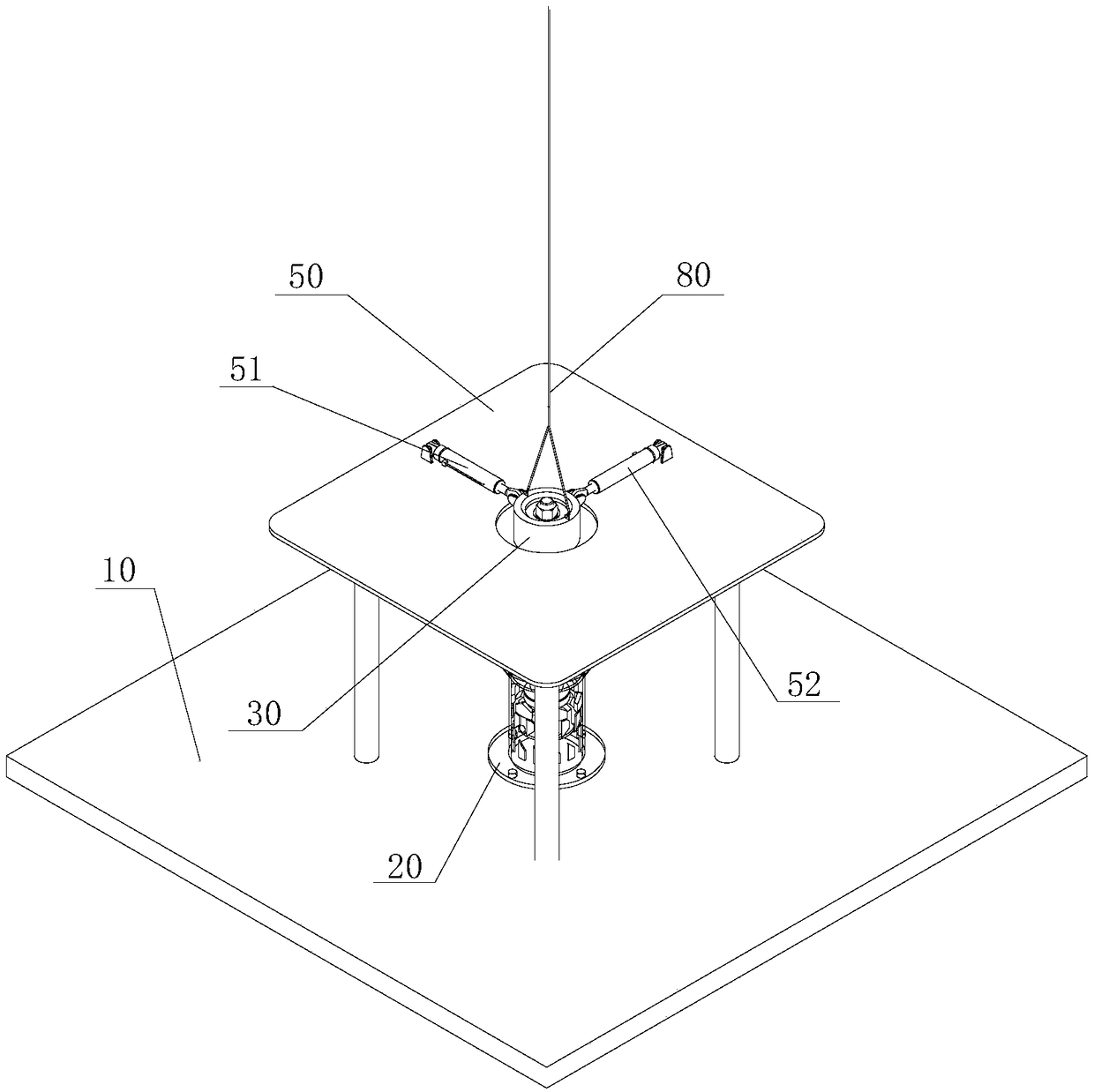

[0019] see Figure 1 to Figure 5 , the test loading system of the tension leg platform tendon connector of the present invention includes a base 10, a tendon connector 20, a top connector 30, a loading unit and a load unit.

[0020] The tendon connector 20 is fixed on the upper surface of the base 10 by screws;

[0021] The top connector 30 is coaxially connected above the tendon connector 20 through a quick joint 40;

[0022] The upper end of the tendon connector 20 and the lower end of the top connector 30 lead out the lower ball shaft and the upper ball shaft in one-to-one correspondence, so that the lower ball shaft and the upper ball shaft can swing about 10° in any direction; The quick joint 40 is connected between the upper end of the lower ball stud shaft and the lower end of the upper ball stud shaft.

[0023] The loading unit includes a loading platform 50 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com