System and method for verifying infinite-mass parachute opening strength of parachute

A parachute and quality technology, applied in the aerospace field, can solve problems such as unsuitable parachutes, and achieve the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

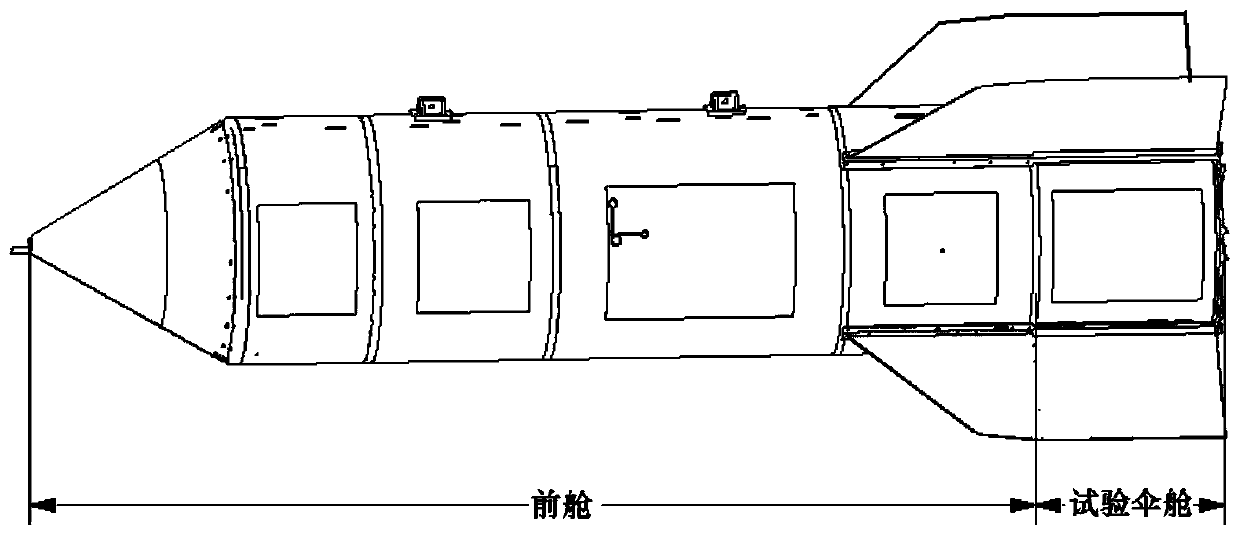

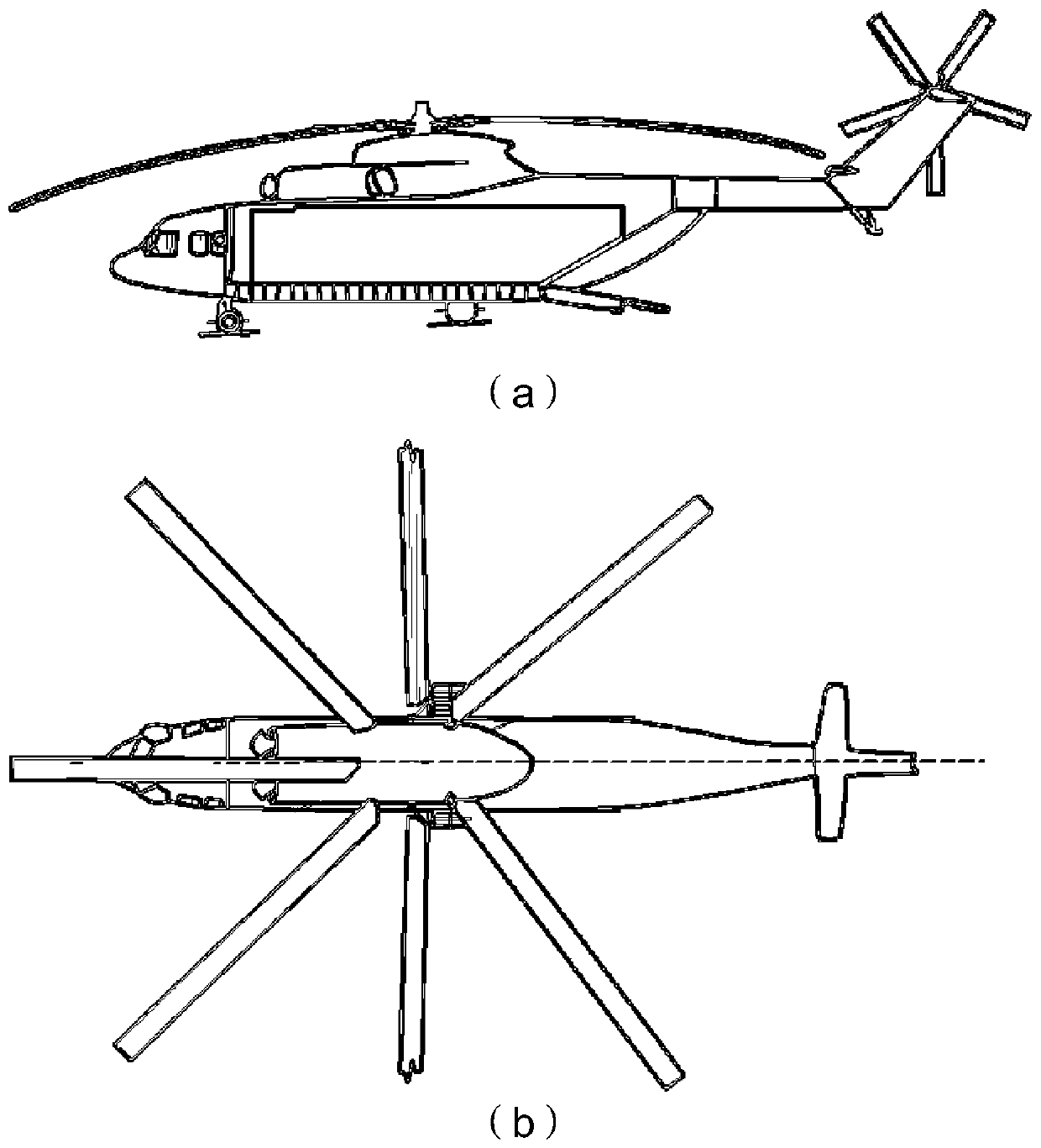

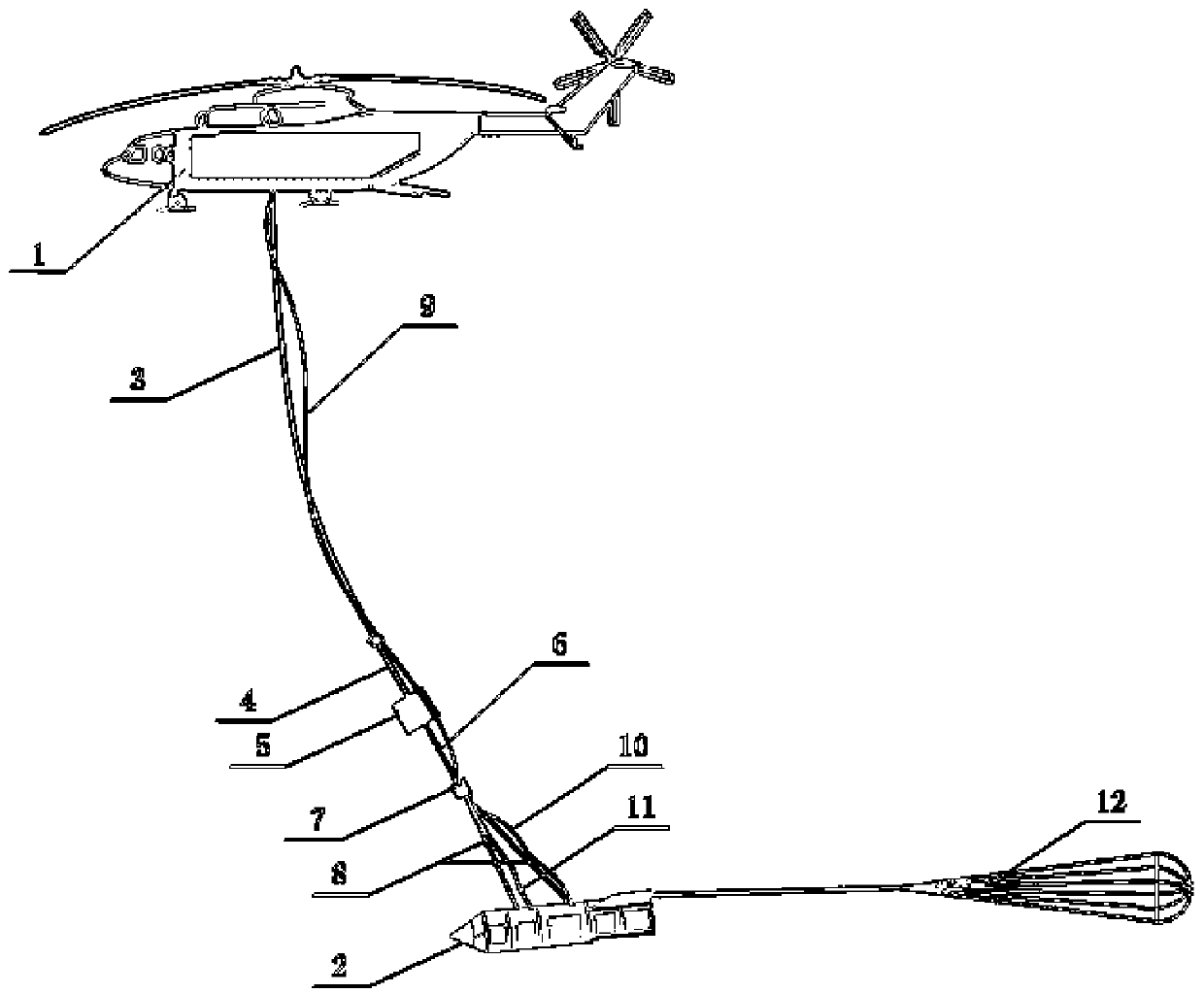

[0055] refer to figure 1 , showing that the embodiment of the present invention provides a schematic structural diagram of a system for verifying the parachute opening strength of infinite mass, including: an airdrop model, a pyrotechnic device, a control device, a measuring device, a parachute device, an airdrop model and a helicopter (such as figure 2 Shown) connection, consisting of the front cabin and the test umbrella cabin.

[0056] The parachute device includes a test parachute and a main parachute, the test parachute is pre-installed in the test parachute cabin, and the main parachute is pre-installed in the front cabin.

[0057] The control device includes an on-board release control device and an on-cabin recovery control device, and the on-cabin recovery control device includes a pitot.

[0058] The pyrotechnic device can be used to complete the release of the airdrop model, and to test the connection and separation of the umbrella cabin and the front cabin.

[005...

Embodiment 2

[0084] refer to Figure 7 , shows a flow chart of the steps of a helicopter airdrop test method for verifying the strength of a parachute under the condition of infinite mass parachute opening provided by an embodiment of the present invention, the method may include:

[0085] After completing the connection between the airdrop model and the helicopter, turn on the manual switch of the measuring device and the recovery control device, and start the measuring device;

[0086] Controlling the helicopter to release the airdrop model through a pyrotechnic device;

[0087] 0.2s after the airdrop universal controller is started, issue the command to destabilize the parachute;

[0088] After the stabilizing parachute is disengaged, judge whether the dynamic pressure measured by the pitot tube meets the parachute opening dynamic pressure requirement of the test parachute through the general controller;

[0089] When the parachute-opening dynamic pressure meets the parachute-opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com