High steepness convex quadric aspherical aberration-free point Sub-Aperture Stitching measurement method

A technology of aperture splicing and measurement method, which is applied in the field of optical testing, can solve the problems of low measurement resolution, difficulty in realization, measurement accuracy limited by scanning motion accuracy, etc., and achieve the effect of reducing cost and improving lateral resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

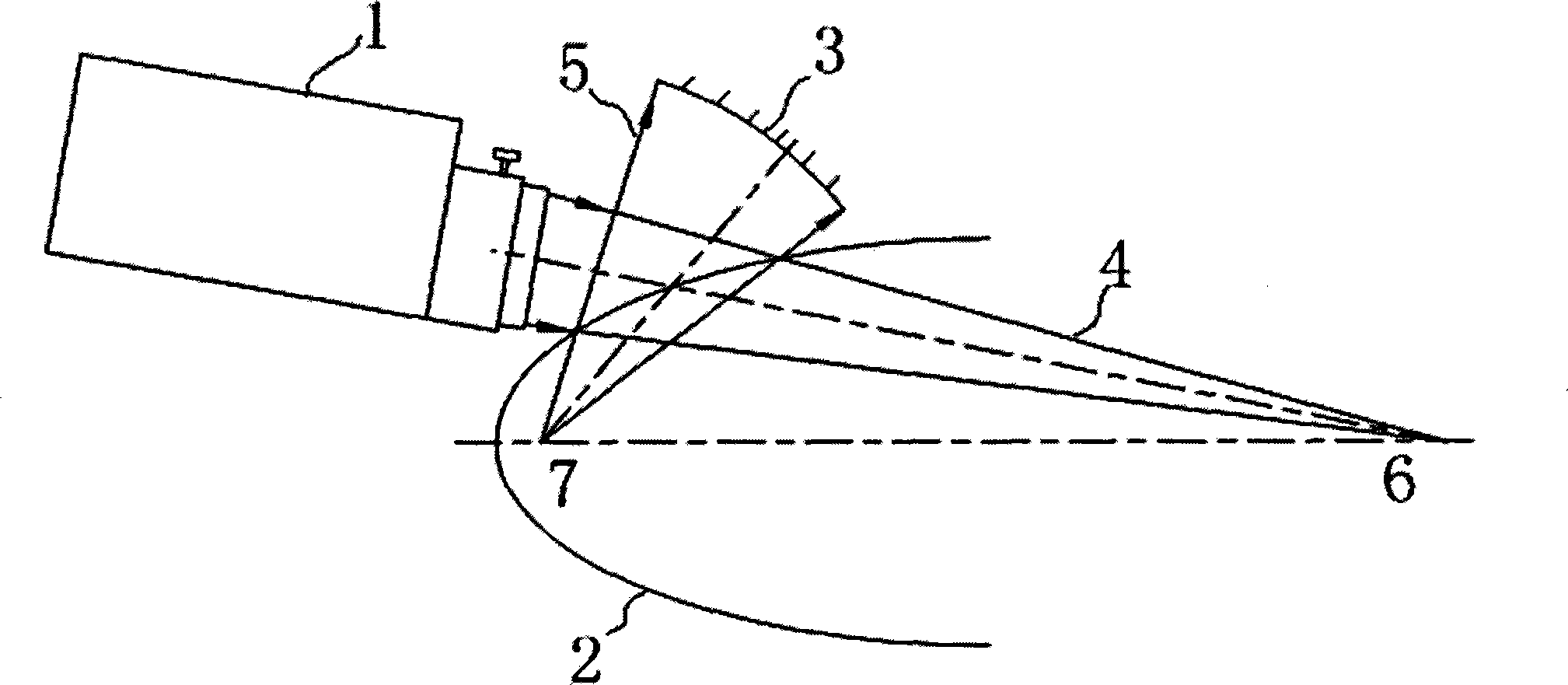

[0028] Such as figure 1 Shown, the system device that the measuring method of the present invention adopts is mainly by wave surface interferometer (for example Fizeau type spherical wave interferometer) 1, measured secondary aspheric surface 2, spherical surface or plane mirror 3, main control computer and corresponding position and Composition of attitude movement adjustment mechanism.

[0029] In order to reduce the impact of environmental vibration on detection, it is recommended to place the entire measurement system device on an air-floating vibration-isolation platform.

[0030] Obtaining the surface error of the measured secondary aspheric surface can be carried out according to the following measurement method of the present invention.

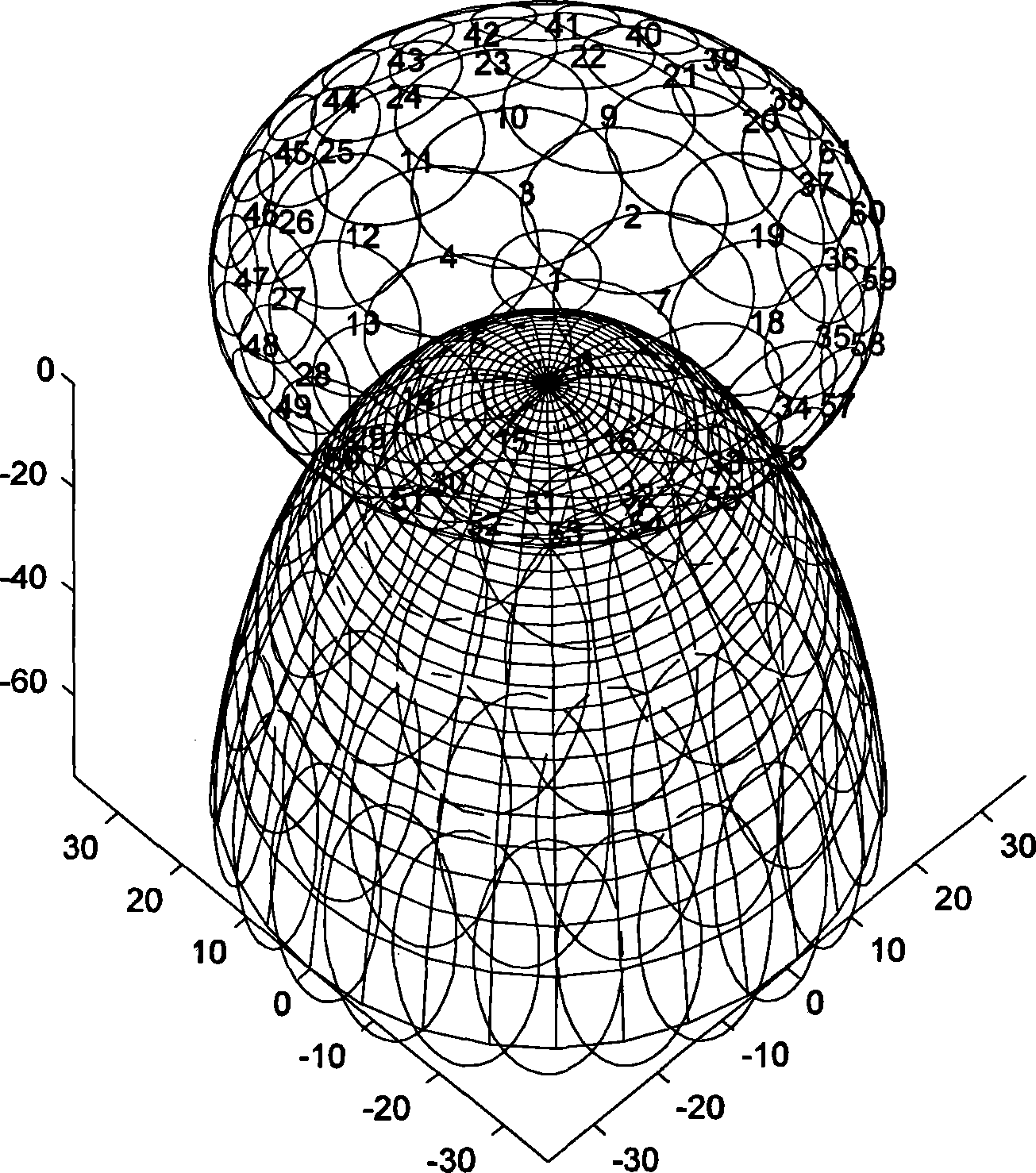

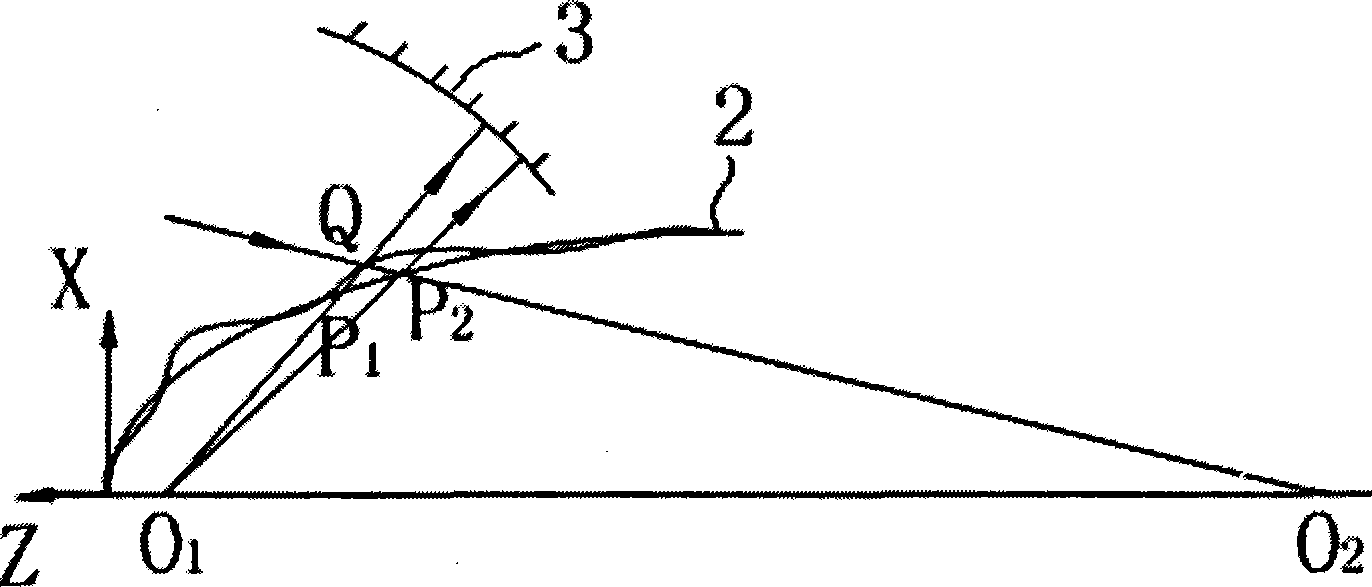

[0031] See figure 2 , first divide the measured quadratic aspheric surface 2 into several overlapping sub-apertures, and mainly consider the sub-aperture overlap coefficient (the ratio of the area of the sub-aperture in the overlap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com