Steel plate full covering supersonic wave detection device and method

A detection device, ultrasonic technology, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as positioning errors, easy slippage, and difficult detection, and achieve The effect of improving detection efficiency and accurate scanning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

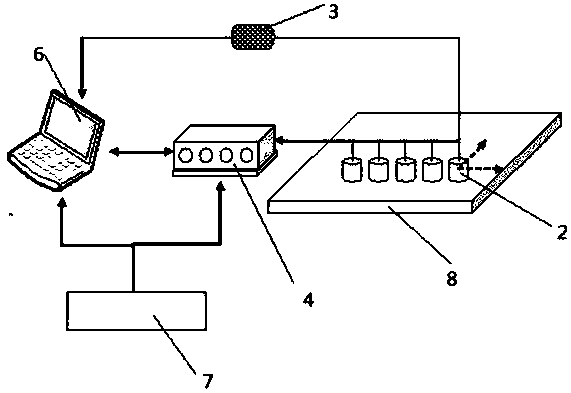

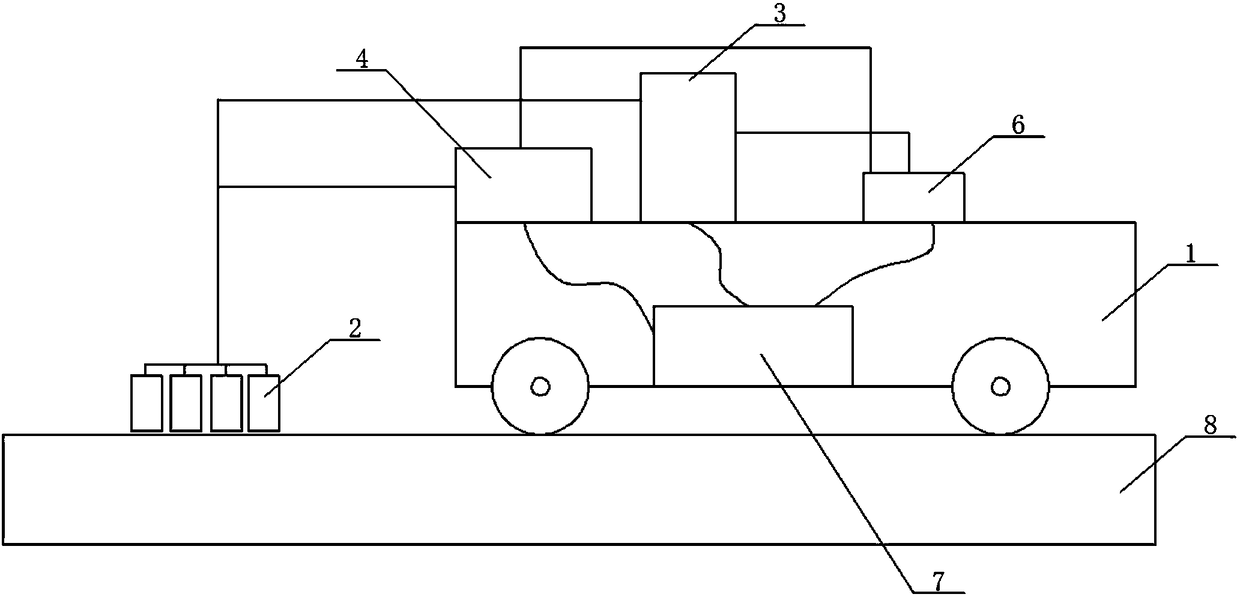

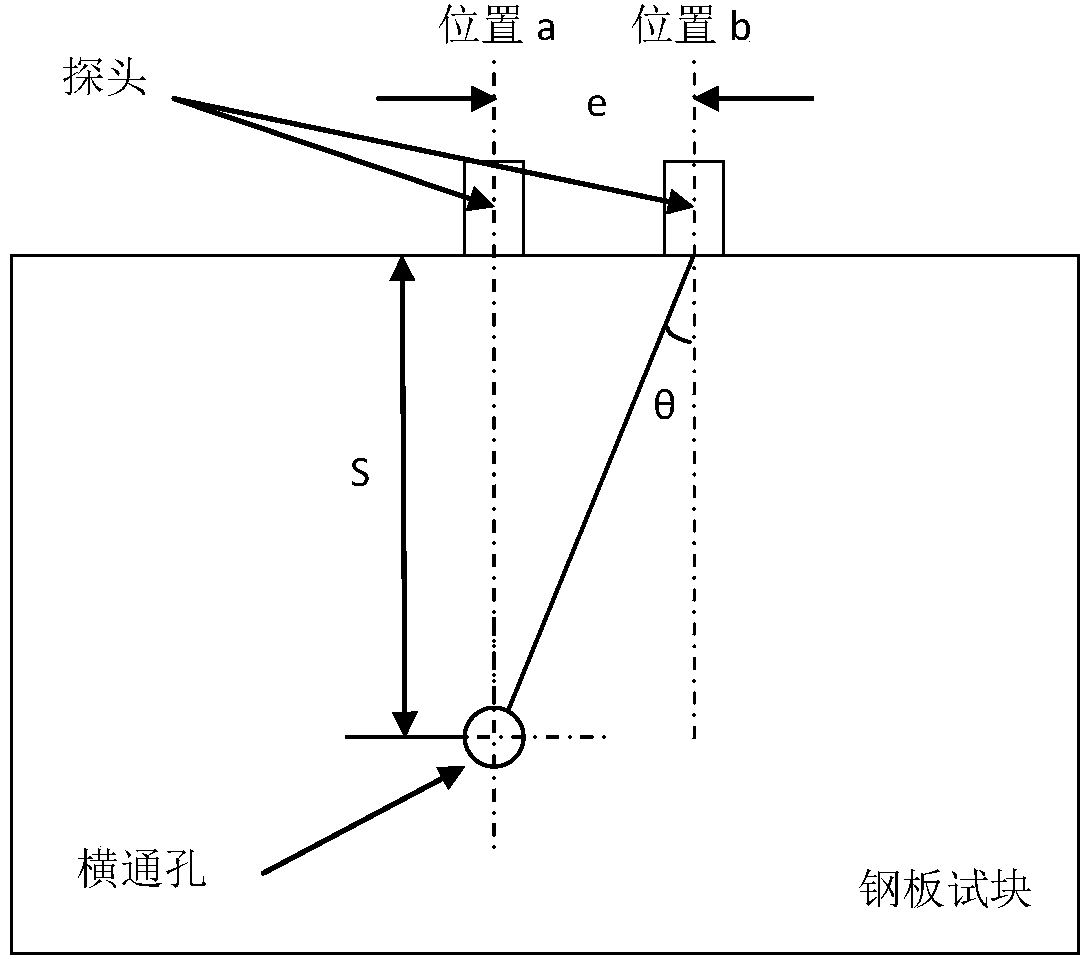

[0037] as attached Figure 1-2 Shown: a steel plate fully covered ultrasonic detection device of the present invention, the device includes a mechanism 1 that can walk freely on the steel plate, and the free walking mechanism includes a wheeled walking body 101; A multi-channel ultrasonic flaw detector 2, a plurality of probes 3 arranged in a linear array connected to the multi-channel ultrasonic flaw detector, a laser movement sensor (laser displacement sensor) 4, a coupling device 5, a host computer 6 and a power supply 7 are provided; The axes of the plurality of probes arranged in a linear array are kept perpendicular to the plane of the steel plate 8 to be detected, and the multi-channel ultrasonic flaw detector 2 controls the plurality of probes 3 arranged in a linear array to send or receive ultrasonic signals, and perform modulus The conversion is transmitted to the host computer 6 (such as a computer), and the laser motion sensor 4 is electrically connected to a plura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com