Single-frame color composite grating stripe reflection mirror surface three-dimensional surface shape measuring method

A fringe reflection, composite grating technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as unfavorable dynamic measurement, slow measurement speed, etc., and achieve the effects of fast measurement speed, high-precision measurement, and high dynamic range.

Active Publication Date: 2014-04-16

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the fringe reflection method usually projects horizontal and vertical fringes separately, and each direction usually needs to project multi-step fringes to demodulate the phase, so the measurement speed is not fast, which is not conducive to dynamic measurement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

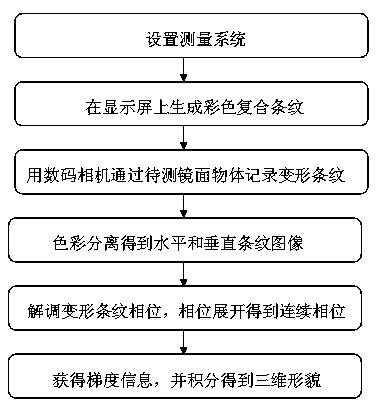

[0035] like figure 1 Shown is the flow chart of the method for measuring the three-dimensional surface shape of the specular surface based on the single-frame color composite grating fringe reflection.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

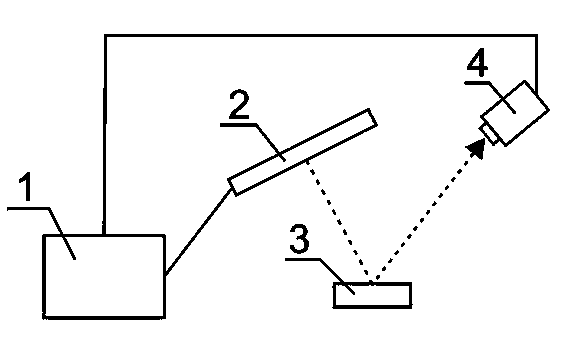

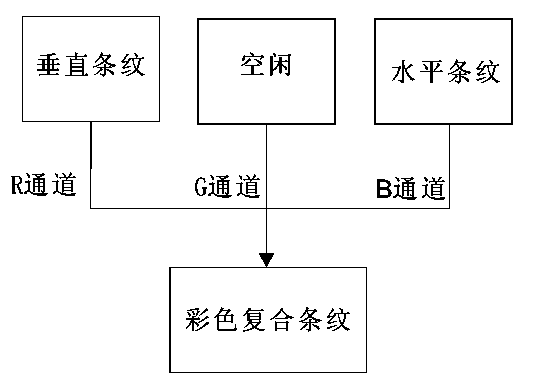

The invention discloses a single-frame color composite grating stripe reflection mirror surface three-dimensional surface shape measuring method. An experiment system comprises a digital camera, a display screen, a mirror surface to be measured and a computer. The experiment system is adjusted to enable the digital camera to observe the display screen through the mirror surface to be measured, horizontal stripes and perpendicular stripes of different colors are generated simultaneously on the display screen, the digital camera is used for recording deformed stripes through an object with the mirror to be tested, horizontal and perpendicular gradients can be obtained by only projecting one frame of color composite grating stripe to the mirror to be tested throughout the measuring process, and the gradients are integrated to obtain three-dimensional shape information. According to the method, rapid and high-accuracy mirror surface object three-dimensional shape measuring can be achieved.

Description

technical field [0001] The present invention relates to the technical field of measurement of irregular surfaces or contours, in particular to a specular three-dimensional surface shape measurement method based on single-frame color composite grating stripe reflection. Background technique [0002] With the development of precision optical processing, automotive painting, industrial manufacturing and product quality inspection, people are increasingly eager to accurately measure mirrors or mirror-like reflection objects, such as the detection of free-form mirrors or lenses (such as glasses), The control of spray paint quality (orange peel phenomenon) on the surface of automobiles, the quality evaluation of surface processing of precision devices, etc. Through the measurement and analysis of various mirror or mirror-like surfaces, the influence of various parameters (such as grinding speed, grinding materials, mechanical vibration, etc.) in the corresponding manufacturing pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/24

Inventor 岳慧敏吴雨祥刘永赵必玉张博易京亚欧中华

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com