Prestress concrete filled steel tube self-balancing type static load test table for bridge static load test

A technology of steel pipe concrete and static load test, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the problems of inability to maintain the level, limited construction, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

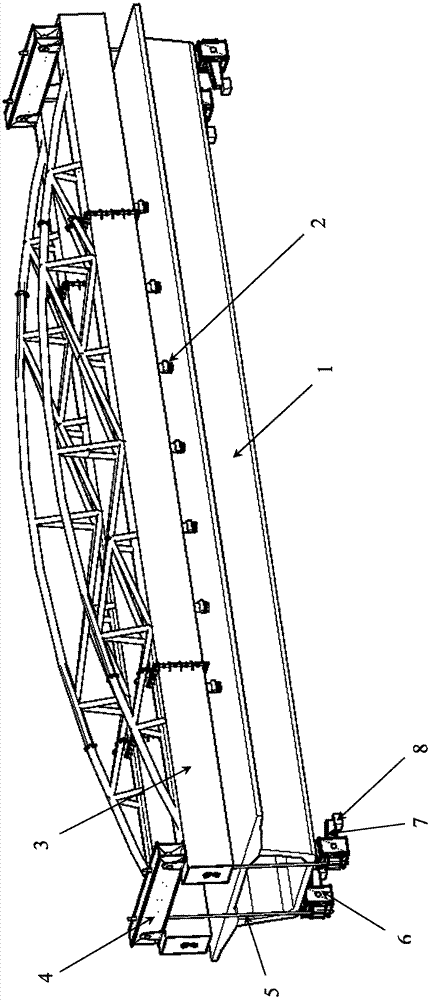

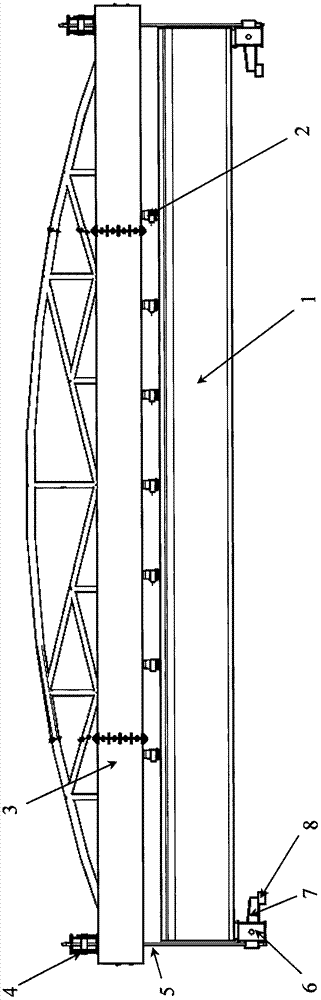

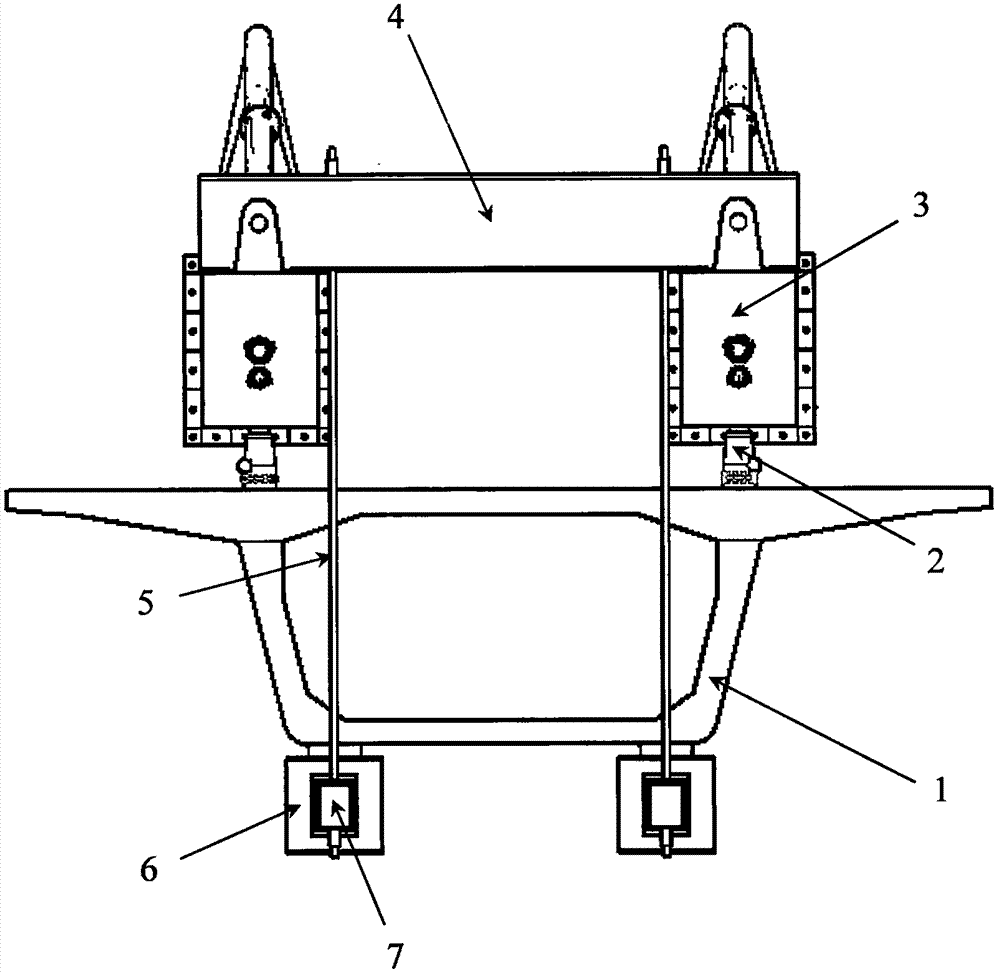

[0026] Such as Figure 1 to Figure 6 As shown, the prestressed steel pipe concrete self-balancing static load test bench for static load test of the present invention comprises a test beam 1, a jack 2, a reaction beam 3, an upper beam 4, a vertical tie rod 5, a support pier 6, Lever beam 7, ground reaction pier 8. The jack 2 is located between the test beam 1 and the reaction beam 3, the reaction beam 3 is located on the test beam 1, the upper beam 4 is arranged at both ends of the reaction beam 3, the vertical tie rod 5 is arranged at both ends of the upper beam 4, and the vertical tie rod 5 One end is connected to the upper beam 4, and the other end is connected to the rear end of the lever beam 7. The lever beam 7 penetrates the support pier 6 and is connected with the support pier 6 by a pin shaft. The front end of the lever beam 7 is connected to the ground reaction pier 8 contradict each other. The transmission path of the test loading force is: test jack 2 - reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com