Construction method of erecting prestressed concrete beam on river

A technology of prefabricated concrete and construction methods, applied in the direction of erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of high cost of hoisting, and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

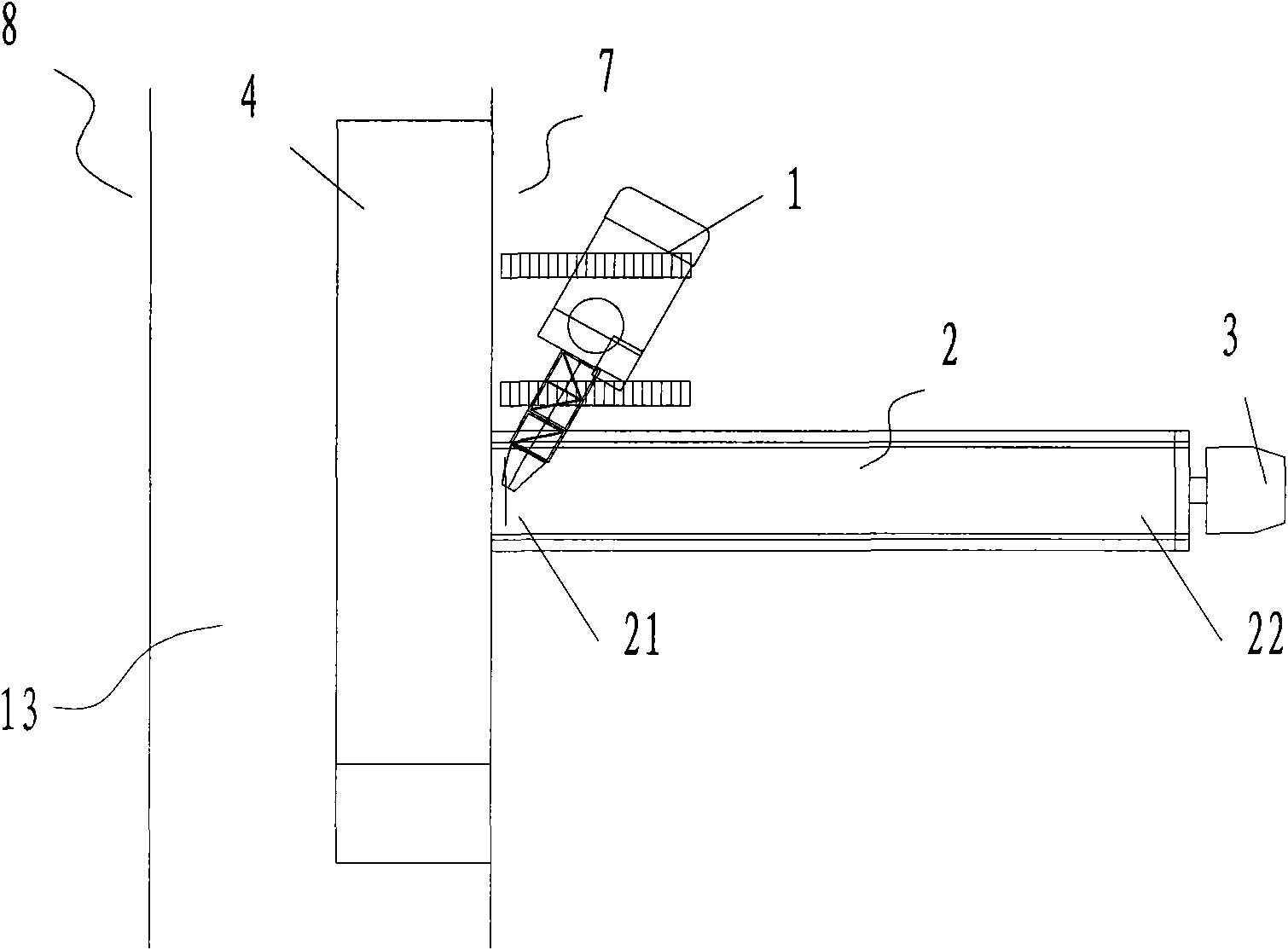

[0040] Embodiment 1: A construction method for erecting precast concrete beams across a river, comprising the following steps:

[0041] 1) park the first crawler crane 1 and the second crawler crane 6 on the first river bank 7 and the second river bank 8 respectively; the precast concrete beam 2 is loaded by the transport vehicle 3; The rear part 21 of the concrete beam 2 reaches the bank of the first river bank 7, and the precast concrete beam 2 is perpendicular to the river 13, as figure 1 As shown; in other specific embodiments, according to the specific conditions of the construction site, when the rear portion 21 of the precast concrete beam 2 reaches the river bank, the precast concrete beam 2 can also be substantially perpendicular to the river 13 to achieve basically the same effect.

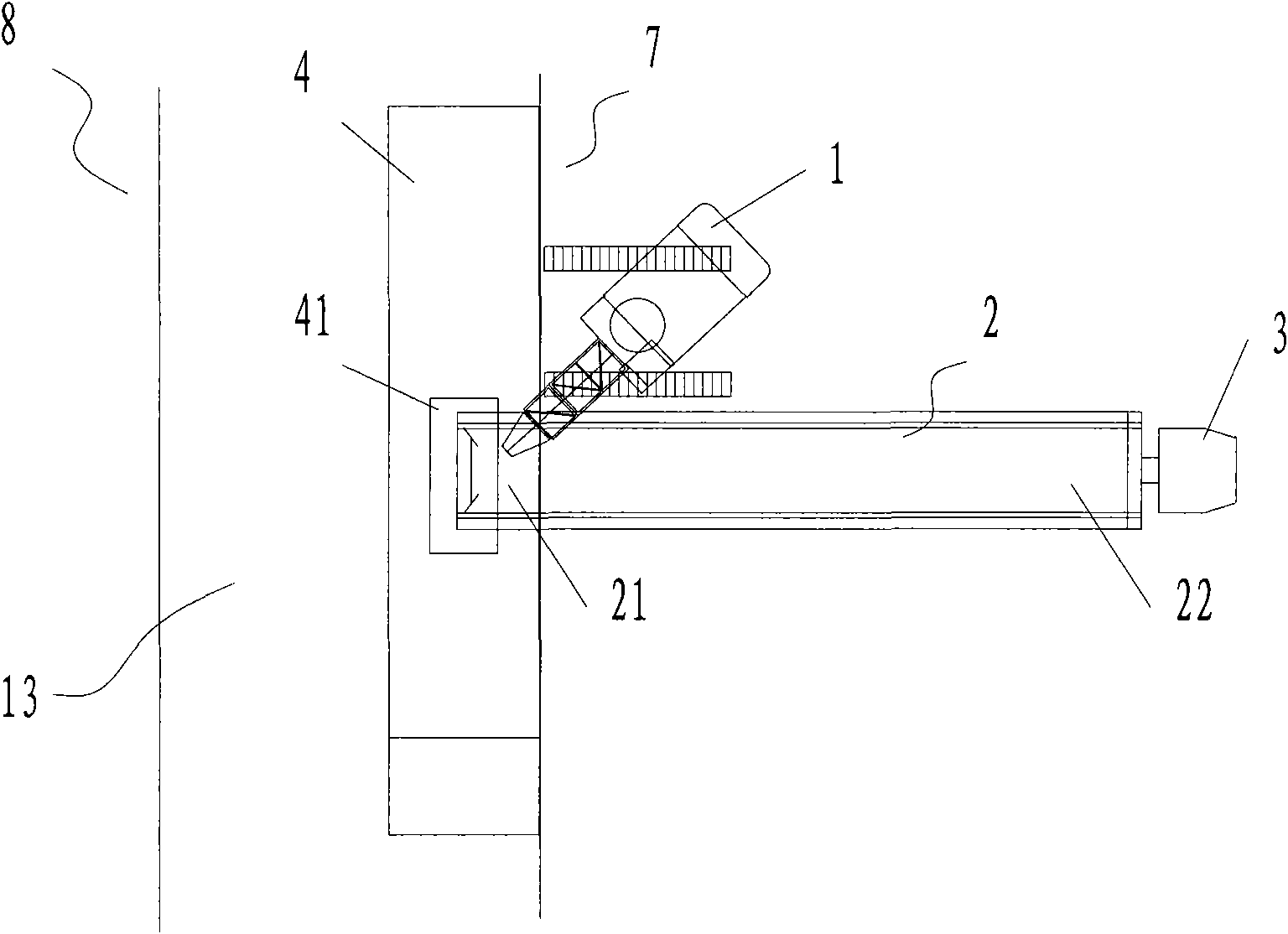

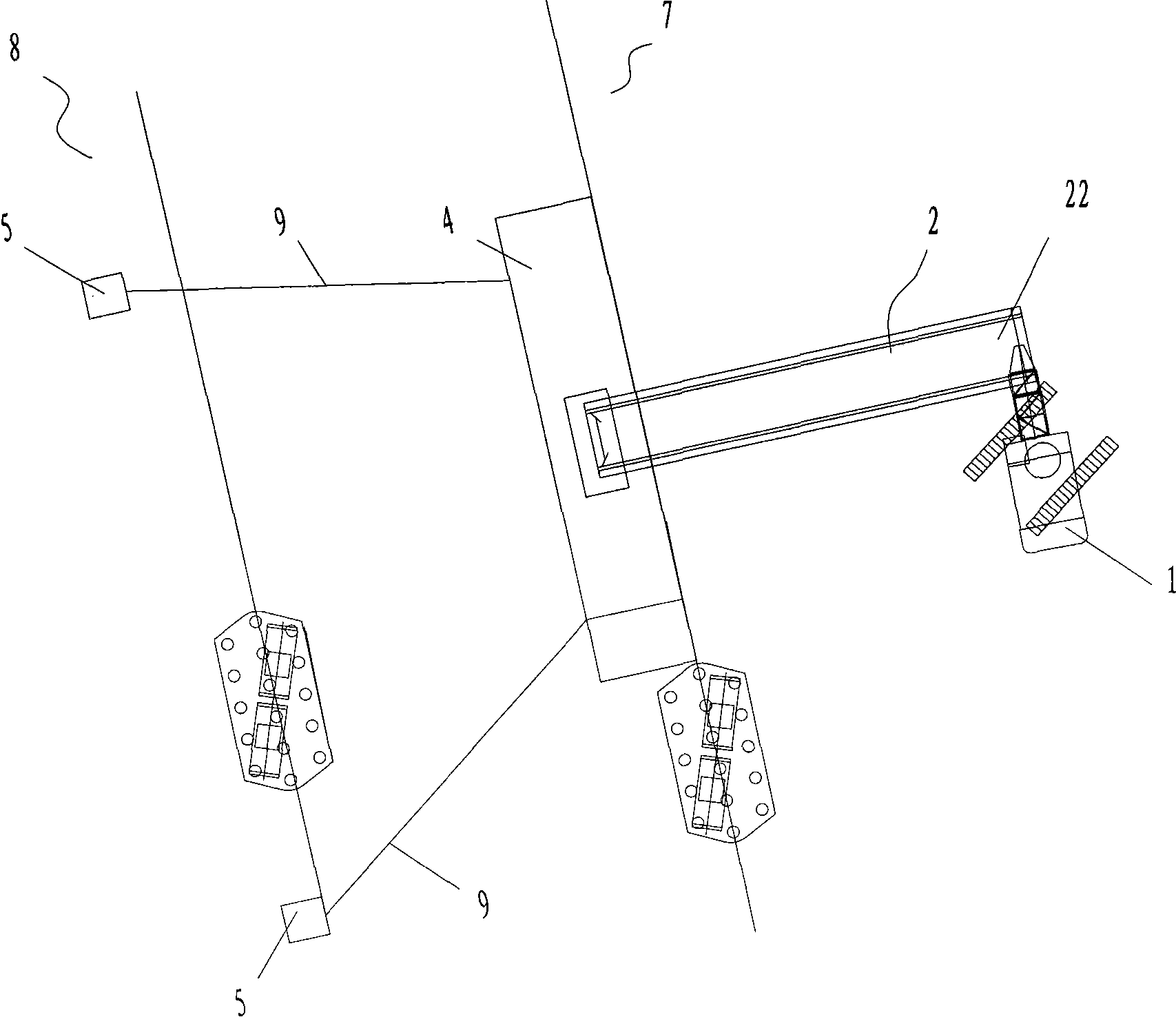

[0042] 2) The rear portion of the precast concrete beam 2 is hoisted on the barge 4 near the bank of the first river bank 7: the first crawler crane 1 lifts the rear portion 21 of the pr...

Embodiment 2

[0048] Embodiment 2: as Figure 7 As shown, the construction method of this embodiment is basically the same as that of Embodiment 1, the difference is that in step 3), during the process of moving the barge 4 to the second river bank 8, a steel wire rope 10 and a hoist are also arranged on the first river bank 7 11 is connected with barge 4, so the motion process of barge 4 is more stable.

[0049] Other steps in this embodiment are the same as in Embodiment 1.

Embodiment 3

[0050] Embodiment 3: as Figure 8 As shown, the construction method of the present embodiment and embodiment 2 is basically the same, the difference is: in step 1), the third crawler crane 12 is provided at the first river bank 7 places; the first crawler crane 1 lifts the precast concrete The front part 22 of the beam 2, the third crawler crane 12 lifts the rear part 21 of the precast concrete beam 2; shore. Therefore, when the conditions on the river bank do not meet the conditions for passing or reversing transport vehicles, the rear part of the precast concrete beam 2 can still reach the bank of the first river bank 7 .

[0051] Other steps in this embodiment are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com