System and method for judging structural damage type of prestress concrete beam based on acoustic emission technique

An acoustic emission technology, a technology of concrete beams, applied in the field of non-destructive testing, can solve the problems of evaluating components, disadvantages, etc., and achieve the effect of high safety, simple operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

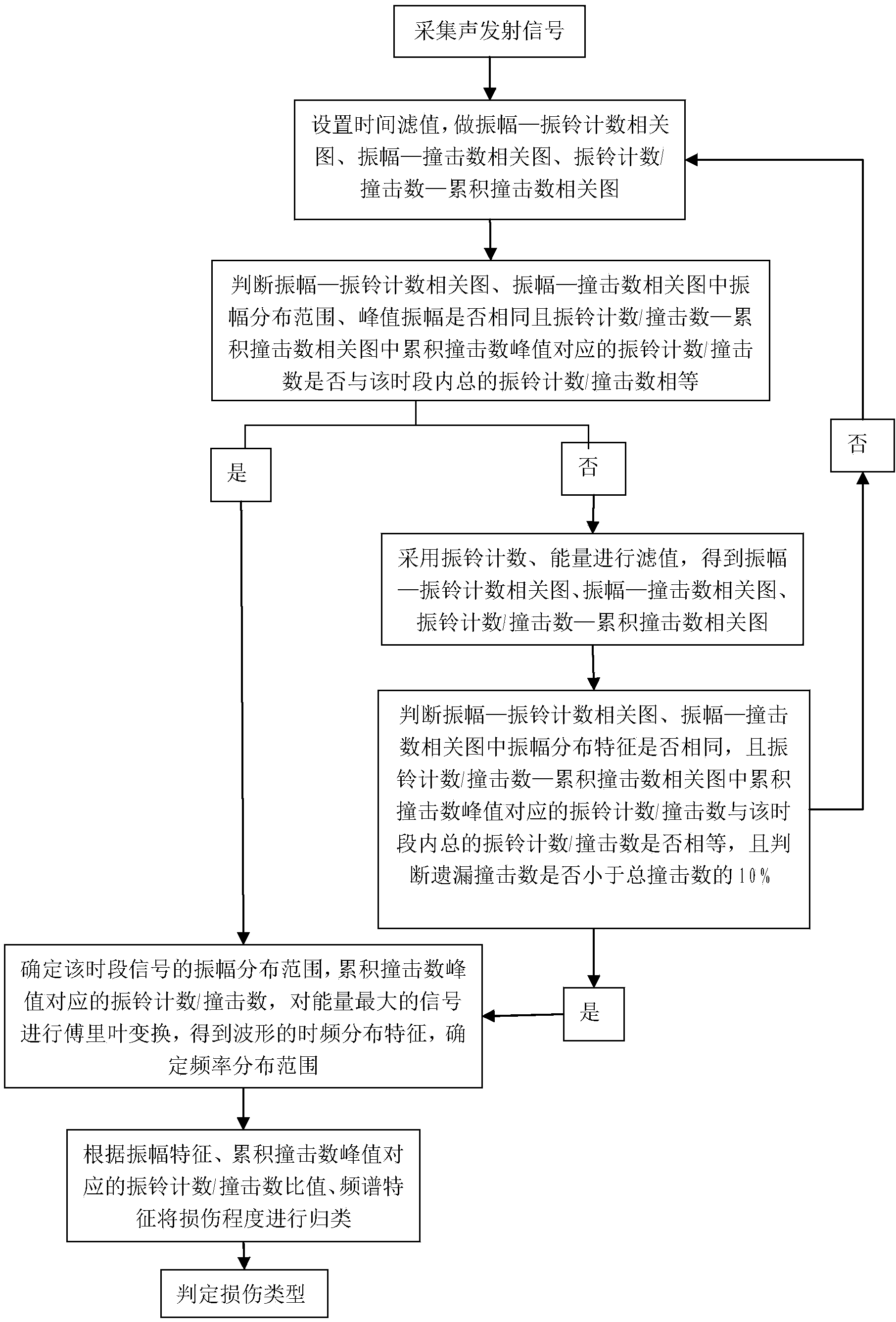

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0034] The invention is mainly used to monitor the damage type of prestressed concrete beams. The acoustic emission signal is dynamic and real-time, and the damage comes from the inside of the component. It is suitable for evaluating the degree of damage to the component and has the advantages of simple operation. It can analyze and judge the development of internal defects of the component in real time. situation.

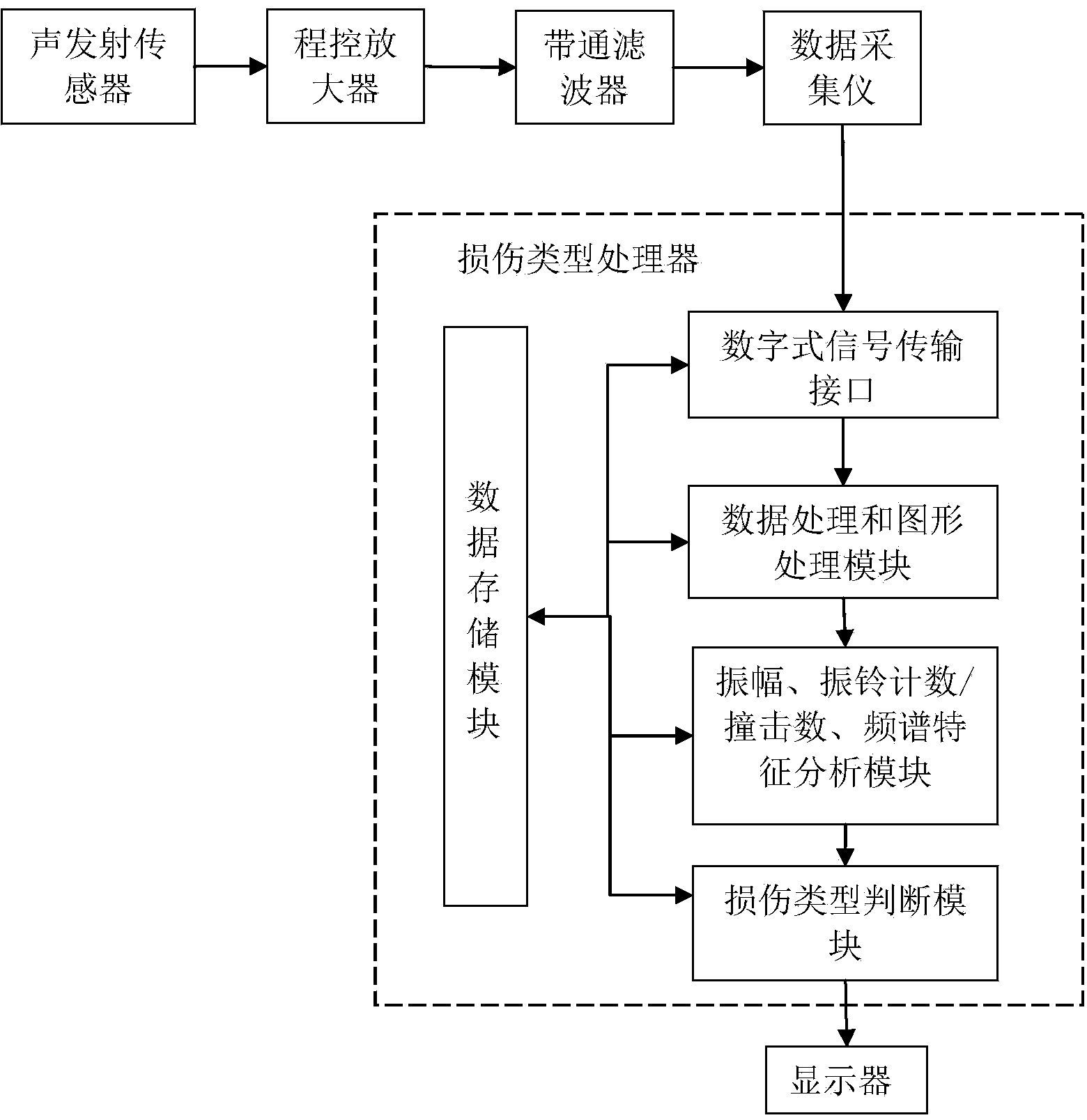

[0035] Such as figure 2 As shown, the system for judging the damage type of prestressed concrete beam structure based on acoustic emission technology in the present invention includes an acoustic emission sensor, a program-controlled amplifier, a band-pass filter, a data acquisition instrument, a damage type processor and a display connected in sequence. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com