Dry-type reactor overheating fault early warning system based on distributed optical fiber sensing

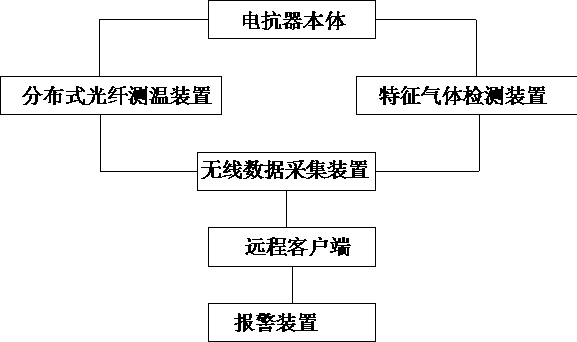

A distributed optical fiber, dry-type reactor technology, applied in signal transmission systems, instruments, measuring electricity and other directions, can solve the problems of underutilization of transformer capacity, shorten the life of transformers, accelerate insulation aging, etc., and achieve perfect monitoring of overheating conditions. Means and early warning management mode, improve the level of operation and maintenance, and prevent the effect of fire damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the content of the present invention is further clearly described below in conjunction with the examples, but the protection content of the present invention is not limited to the following examples. In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

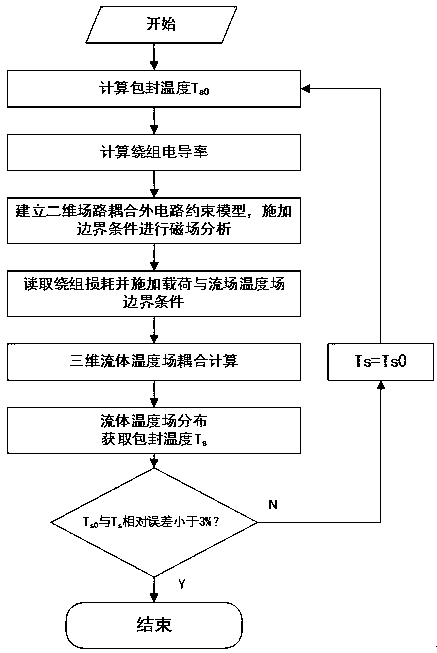

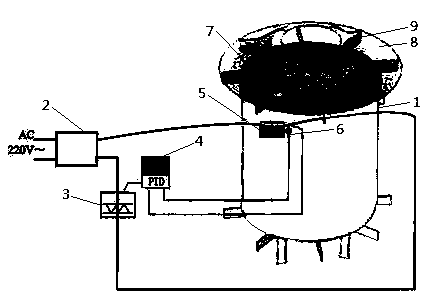

[0023] The dry-type reactor overheating fault warning system based on distributed optical fiber sensing is obtained through the following steps:

[0024] The first step is to obtain the temperature field distribution and hot spot area of the dry-type reactor under normal operating conditions

[0025] The prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com