Prestressed assembly integrated concrete frame structure system and construction method thereof

A frame structure and prestressing technology, applied in truss structures, building components, building structures, etc., can solve problems such as difficult connection of nodes, difficulty in meeting the requirements of different seismic fortification areas, and complex structural forms, so as to reduce the use of formwork and The effect of turnover material loss, simplification of construction operation process and improvement of working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

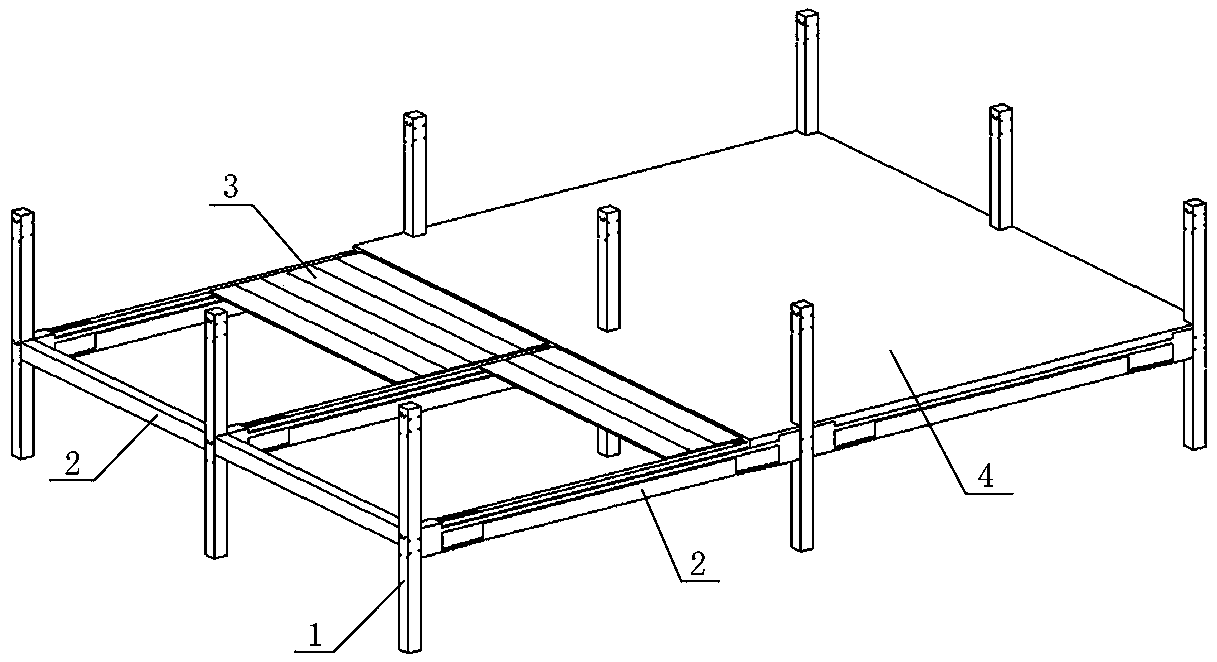

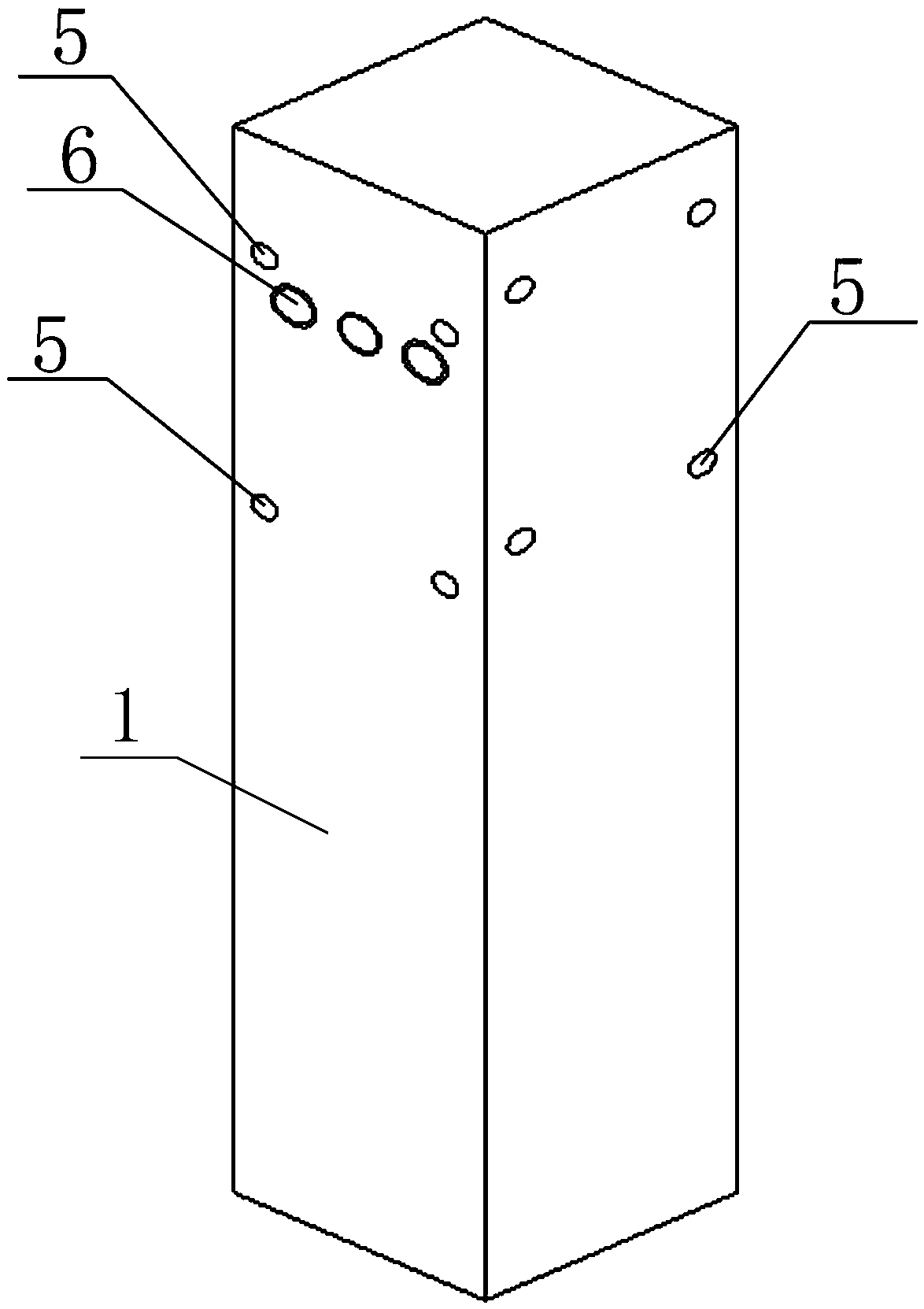

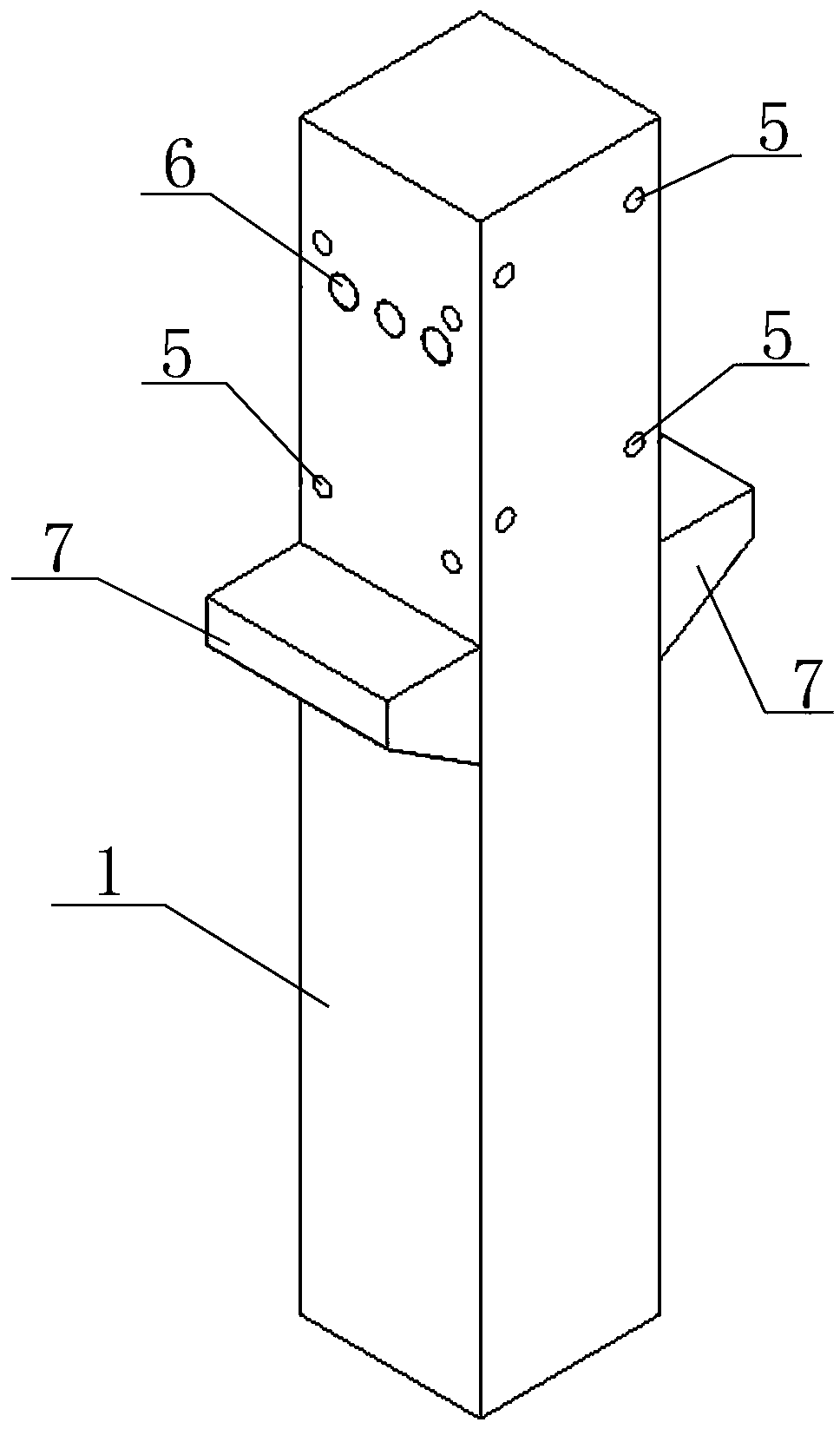

[0050] Such as Figure 1-13 As shown, this prestressed assembled integral concrete frame structure system includes prefabricated reinforced concrete columns 1, prefabricated prestressed concrete beams 2, prefabricated prestressed concrete slabs 3 and floor slabs poured on prefabricated prestressed concrete slabs 3 Layer 4; the prefabricated reinforced concrete column 1 is provided throughout the length, on the prefabricated reinforced concrete column 1, the connection position with the prefabricated prestressed concrete beam 2 is provided with a column first tunnel 6 passing through the post-tensioned curved prestressed tendon 12 and Through the post-tensioned high-strength finish-rolled threaded steel bar 13, the second channel 5 of the column; in the prefabricated prestressed concrete beam 2, a row of pre-tensioned prestressed tendons 11 is provided near the bottom position, and in the prefabricated prestressed concrete beam 2 There is a beam first tunnel 9 adapted to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com