Post stressed concrete beam pipe mudjacking agent

A technology for concrete beams and grouting agent, which is applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of aluminum powder gas generation greatly affected by ambient temperature and "hydrogen embrittlement of prestressed steel bars" , to achieve the effect of excellent water retention performance, good filling, and low sensitivity to temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] High-efficiency water-reducing component: 2.2%

[0036] Early expansion component: 8.5%

[0037] Middle and late expansion component: 35%

[0038] Mineral admixture composition: 52.95%

[0039] Antirust component: 0.5%

[0040] Water retaining agent component: 0.04%

[0041] Defoaming component: 0.6%

[0042] Retarding component: 0.2%

[0043] Air-entraining component: 0.01%

[0044] The present invention is obtained by uniformly mixing each component according to the above weight percentage.

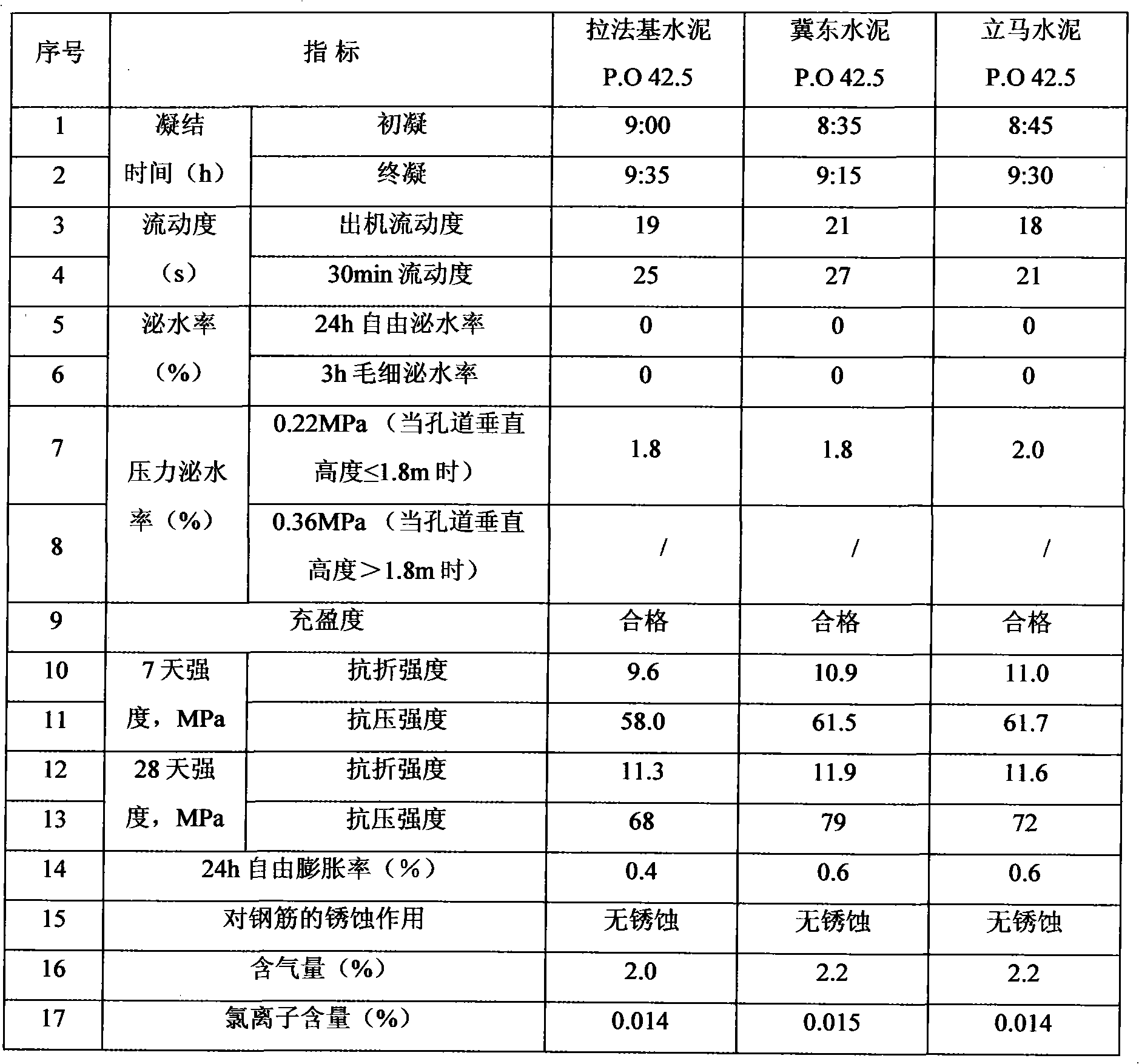

[0045] See Table 1 for the performance of the grouting material formed after the present invention mixed with cement (replacing cement 13%) and water prepared by the above formula.

[0046] Physical properties of grout

[0047] Table 1

[0048]

[0049] Note: the water-binder ratio used is (that is, water / (cement+grouting agent) is 0.31), the dosage of the present invention is internal blending, and the dosage of the grouting agent is 13%.

Embodiment 2

[0051] High-efficiency water-reducing component: 1.8%

[0052] Early expansion component: 6.0%

[0053] Mid-late expansion component: 45%

[0054] Mineral admixture component: 45.95%

[0055] Antirust component: 0.5%

[0056] Water retaining agent component: 0.03%

[0057] Defoaming component: 0.4%

[0058] Retarding component: 0.3%

[0059] Air-entraining component: 0.02%

[0060] The present invention is obtained by uniformly mixing each component according to the above weight percentage.

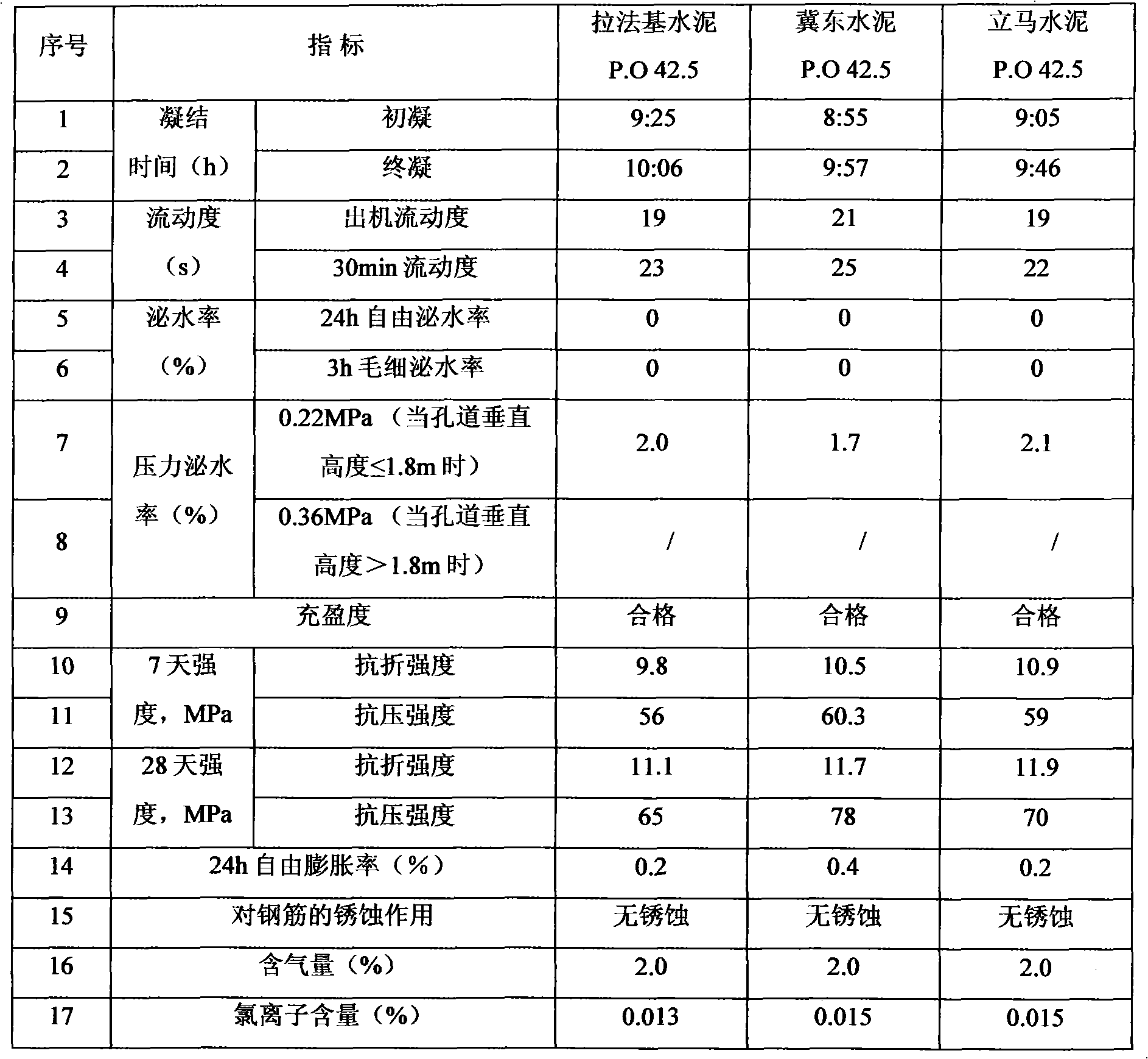

[0061] See Table 2 for the performance of the grouting material formed after the present invention mixed with cement (replacing cement 13%) and water prepared by the above formula.

[0062] Physical properties of grout

[0063] Table 2

[0064]

[0065] Note: the water-binder ratio used is (that is, water / (cement+grouting agent) is 0.32), the dosage of the present invention is internal blending, and the dosage of the grouting agent is 13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com